Creator: Maury Wooden, VP Strategic Advertising

The financial and quality-of-life advantages of electrification is driving the adoption of HV to 48V DC-DC conversion throughout many markets. Built-in high-voltage to 48V energy modules have gotten extra widespread in EVs and different purposes as battery voltages improve. Find out how bidirectional fixed-ratio bus converter modules are optimizing energy supply in these programs.

Bidirectional, power-dense DC–DC converters are the best resolution for the brand new and difficult use circumstances offered by machine electrification throughout quite a few industries. This paper demonstrates how high-efficiency, fixed-ratio DC–DC converter modules are able to supporting transient regenerative hundreds with out the associated fee and complexity of liquid cooling.

Electrification, the societal motion away from fossil gasoline powered machines, is sweeping throughout all industrial, car and aerospace/protection gear classes. The financial and cultural forces driving this motion are well-known and customarily undisputed. Electrification has each environmental advantages (decrease related carbon emissions, for instance) and key efficiency advantages reminiscent of high-torque motors enabling excessive ranges of acceleration in electrical automobiles.

Excessive DC voltages starting from 270V as much as 1,000V are generally utilized in electrical gear and automobiles as a method to cut back energy losses within the bussing or cabling between the ability supply and the ability load (linear and rotational motors, actuators, sensors, processors, point-of-load low voltage regulators, and so on.). Excessive voltages additionally allow the supply of excessive ranges of transduced mechanical drive, each linear displacement and rotational displacement.

DC–DC converters play an important function in remodeling excessive voltages to decrease voltages, with or with out isolation, regulation and reverse operation, in electrical automobiles, information facilities, communications programs and industrial gear of all sorts. These energy converters might be carried out utilizing discrete parts or in modular bundle kind. DC–DC converters energy modules are the main focus of this text.

Over the previous 10 years or so, the dominant DC subsystem energy supply community (PDN) voltage of 12V has begun to transition to 48V (54V in information facilities), pushed by the numerous improve in load energy necessities, and the necessity to keep security extra-low voltage (SELV) ranges, heralding the emergence of HV-to-48VDC converters. Coincident with this evolutionary change of subsystem PDN voltage has been the adoption of 48V-centric dc–dc converter energy modules, which have quite a few ease-of-use, energy density, energy scaling and weight advantages, and which help regeneration (the return of vitality to the first energy supply).

Using excessive DC voltage is ramping in gear, automobiles and infrastructure

Electrolytic batteries, utilizing a fast-evolving number of chemistries, are sometimes used as each high-voltage and low-voltage dc energy sources and are clearly very best for cellular (non-tethered) and handheld purposes. The rechargeable nature of many battery sorts, from lead acid cells to the newest sodium-ion and graphene sorts, in addition to trendy supercapacitors, help regenerative vitality use circumstances that in mixture are destined to avoid wasting huge quantities of vitality globally.

In electrical automobiles, it’s common to see nominal battery pack voltages of 400VDC and 800VDC. Sooner or later, 800V battery packs are more likely to dominate, attributable to escalating vitality density traits. Gentle hybrid automobiles usually use 48VDC batteries, with some producers electing to make use of 12VDC multi-cell packs. Electrical automobiles embody not solely cars but additionally industrial and agricultural automobiles (together with building automobiles reminiscent of excavators and tractors) in addition to all forms of leisure car platforms (private watercraft, 4×4 off-road automobiles, snow machines, bikes, and so on.). With few exceptions, notably driving vary and the time required to refuel or recharge the car, the electrical variations of those car sorts are inclined to have superior end-user efficiency (reminiscent of acceleration, torque and journey high quality) than their inside combustion engine counterparts.

Why is 48VDC energy distribution changing 12VDC energy distribution?

Greater distribution voltage delivers the identical energy with decrease present. As a result of distribution energy losses (sometimes utilizing copper or aluminum busbars or cables) are a operate of the sq. of the present (P = I2R), in excessive energy purposes these substantial conduction losses attributable to busbar and cable resistance might be diminished by utilizing increased distribution voltages. Busbars and cables are sized in keeping with present carrying capability (known as ampacity), and a 4x improve in voltage and a 4x lower in present has a considerable influence on sizing, weight and price. For instance, to conduct 200A, a copper busbar wants a cross-sectional space of about 0.0625 sq. inches, whereas to conduct 800A, a copper busbar wants a cross-sectional sq. of about 0.3125 sq. inches, a distinction of an element of 5 [3]. The dimensions and weight of busbars and cabling related to 48VDC are thinner, lighter and thus cheaper than these related to 12VDC energy supply networks.

Exploring the capabilities of excessive voltage to 48V conversion with a fixed-ratio converter module

The technical capabilities of superior 48V energy modules unlock new ranges of effectivity and efficiency. For instance, the Vicor BCM6135 sequence is a household of fixed-ratio, remoted (4242V), bus converter energy modules with built-in magnetics and by design are inherently bidirectional, supporting regenerative battery purposes.

One member of this household, a 2.5kW steady-state-rated module, has a ratiometric conversion “Ok issue” (the equal of transformer turns ratio) of 1/16 and is rated to transform nominal 800V to nominal 50V.

Attributable to its circuit topology and zero-voltage and zero-current switching, its peak effectivity is 97.3%, leading to 67.5W of energy loss as warmth (2.7% x 2.5kW) to thermally handle at peak energy supply (3.1kW) for a given case temperature of TCASE of 70°C. The volumetric energy density is excessive at 159kW/L (module dimensions are 61.3mm by 35.4mm by 7.3mm); module weight is 58g, yielding a steady massimetric energy density of 43.1W/g.

Determine 1: BCM6135 Bus Converter Module.

The BCM6135 (see Determine 1) helps instantaneous bidirectional start-up and steady-state operation. Moreover, the BCM6135 acts as a capacitance multiplier, scaling the majority capacitance throughout the high-voltage (HI) bus to the low-voltage (LO) bus by the sq. of the Ok issue (162 = 256). This attribute saves the associated fee, weight and area of the bypass or bulk capacitors that in any other case can be required on the low-voltage bus.

Moreover, the excessive switching frequency of the BCM allows extraordinarily quick load step transient (di/dt) efficiency of 8 MA/s, permitting the module to interchange auxiliary batteries and supercapacitors in any other case wanted to help the transient load steps in demanding purposes, together with these in high-performance computing and electrical automobiles.

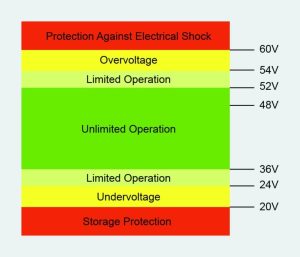

The BCM’s vast enter voltage vary (from 520V to 920V) helps all kinds of DC voltage distribution requirements. Extensive enter voltage vary is likely one of the attributes of the proprietary Sine Amplitude Converter (SAC) topology used within the BCM. The significance of vast enter voltage vary is properly illustrated by the advice of the German Affiliation of the Automotive Trade, or VDA, VDA 320: Electrical and Digital Elements in Motor Automobiles – 48V On-Board Energy Provide–Necessities and Checks (model 01/20/2025), also called LV 148, developed by the automotive OEMs Audi, BMW, Daimler, Porsche and Volkswagen as a typical OEM normal for 48VDC voltage vary parts. This steering recommends that the battery possess a vast voltage working vary between 36V and 52V, restricted working modes between 24V and 54V (see Determine 2).

Determine 2: VDA 320 48VDC voltage vary advice.

The skinny (7.3mm) BCM6135 module household is overmolded and electroplated for thermal agility, shielded and interconnected by floor mount terminals or through-hole pins, and the three-dimensionally interconnected ChiP bundle affords low thermal impedance and excessive thermal adeptness, together with a coplanar thermal interface to warmth sinks and chilly plates.

Regenerative energetic suspension with out energetic cooling

The BCM6135 conversion effectivity at excessive ambient temperature (70°C) and sourcing 50A output present at 48V is often 97.3%. This high-voltage to 48V energy module is commonly utilized in steady load purposes, however it is usually properly suited to transient pulse load purposes and relying on the heart beat obligation cycle of the load, probably can be utilized with passive cooling (no compelled air or liquid cooling). Regenerative electrical car energetic suspension (which might be mixed with energetic anti-roll management) is a superb instance of a bidirectional use case that’s characteristically transient. The linear motors that actuate the energetic suspension are activated solely when bumps and potholes are encountered. The sort of system utility is finest modeled and described utilizing peak energy conversion metrics.

In years previous, 12VDC has been proven to be insufficient (inside cheap dimension, weight and price constraints) to energy energetic suspension motors. Observe that an electrical car’s 800VDC essential battery could possibly be used to energy an energetic suspension subsystem, however working 800VDC to the car’s periphery reduces security, notably to first responders to crash accidents.

The assured peak energy ranking of this BCM6135 mannequin is 3.1kW for 20ms, with 25% obligation cycle, on the low finish of its working voltage vary (i.e., low line operation; the total steady working vary is 17V to 57.5V). As might be anticipated, the height energy output derates for longer durations of the transient demand. Growing an application- stage peak energy specification for an energetic suspension is advanced, as worst-case highway floor profile, cooling technique, dimension, weight and price constraint targets can fluctuate enormously. Nevertheless, to reduce dimension, weight and price, it’s sometimes strongly most popular to make use of passive thermal administration for the energetic suspension DC-DC converter subsystem (i.e., conductive/convective heatsinks however no fan compelled air or circulating liquid cold-plates).

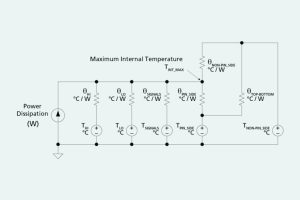

The design problem to satisfy these constraints quantities to validating that the ability converter module can meet the height transient load calls for with out incurring thermally activated module shut down. The BCM6135 is electroplated on each side, and the warmth sink(s) ought to ideally contact each side of the bundle. The module, which has a bundle thermal capacitance of 44.5 J/Ok, contains an inside temperature sensor, which together with the 2 sided thermal mannequin, allows estimation of the utmost inside MOSFET “junction” temperature as proven in Figures 3 and 4.

Determine 3: BCM6135 two-sided cooling thermal resistance mannequin utilizing electrical component

equivalence.

Determine 4: BCM6135 two-sided annotated thermal resistance mannequin with component worth annotation.

Estimation of inside module temperature profile

The thermal capacitance is used to calculate the thermal time fixed of the module throughout a transient thermal occasion. This time fixed is the product of thermal capacitance and thermal resistance. The worth given for thermal capacitance in product datasheets is a calculated worth that assumes the product is at a uniform temperature internally (all through the module) always throughout the transient thermal occasion. It is a linearized simplification, nevertheless it permits the product designer a technique to shortly estimate the temperature-versus-time habits of the product early within the product design cycle. The simplification of uniform inside temperature additionally implies that the thermal time fixed higher displays precise product efficiency when utilized for double-sided cooling of the 48V energy module utilizing warmth sinks.

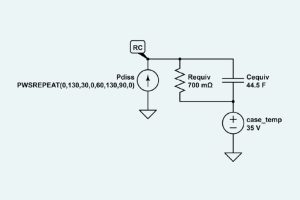

For instance, an equal circuit to mannequin the thermal resistance of the BCM6135 is proven in Determine 5. Electrical resistors are analogous to thermal resistances in items of levels Celsius per watt [°C/W]. A present supply is analogous to a warmth supply in items of watt [W]. A voltage supply is analogous to a temperature supply on this circuit mannequin with items of levels Celsius [°C].

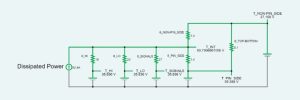

Determine 5: BCM6135 thermal mannequin equal electrical circuit assumes bundle high and backside cooling with an equal thermal resistance of 0.7°C/W and case temperature of 35°C.

The equal circuit assumes bundle high and backside cooling with an equal thermal resistance of 0.7°C/W and case temperature of 35°C, thermal capacitance of the module of 44.5J/Ok, and that the module dissipates 130W throughout 30 seconds-on, 30 seconds-off repeatedly repeated pulses.

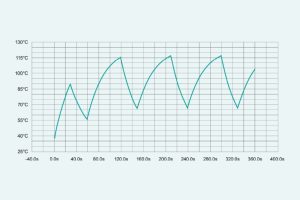

Simulation outcomes for this circuit are proven in Determine 6; the working situations are 520 VHI, 32.5 VLO, 80A low-side peak output present (2.6kW peak output energy). Through the first energy pulse, the utmost inside temperature will increase to about 90°C. The following pulse reveals a rise in most inside temperature to about 115°C. Repeated pulses would present most inside temperature stays round 115°C.

Determine 6: Simulated BCM pulsed energy thermodynamics below the working situations 520 VHI, 32.5 VLO, 80A low-side peak output present. First energy pulse reveals the utmost inside temperature will increase to about 90°C, adopted by a rise to about 115°C. Repeated pulses would present most inside temperature limits to about 115°C.

Utility testing of the module ought to at all times be performed to validate preliminary modeled estimates of transient efficiency and to correctly design a passive convective heatsink.

Lab check outcomes

The BCM6135 is inherently bidirectional with instantaneous switching of the directional mode of operation. The conversion effectivity of the module is similar whatever the path of present move.

Within the regenerative energetic suspension utility, the 800V battery is sourcing present when the car is touring over clean highway surfaces and the suspension actuation motor is the 48V load. When a pothole is encountered by the car, the motors within the suspension momentarily develop into mills (compression), and the voltage on the low aspect of the BCM will increase above the voltage of the 800V battery divided by the conversion Ok issue (Ok = 1/16 on this utility). This distinction in potential causes the bus converter to swap the path of present move, with out inside loop controller intervention. The 800V battery then momentarily turns into the load (rebound) and recovers vitality by charging by its battery administration system circuit.

As soon as the displacement from the pothole has subsided, the bus converter will as soon as once more step down the 800V battery and provide present to the suspension linear motors. All of this happens with out intervention by the car’s on-board processors. The frequency of those suspension actuations ranges from about 1Hz to 10Hz. Apparently, the highway floor profile is basically an analog of the bus converter load step dynamics.

It’s the potential distinction between the bus converter excessive and low sides that defines the present amplitude and path.

Think about that the load on the low aspect is a passive load (reminiscent of a resistor) and on the excessive aspect there’s a battery with a possible of 800V. The BCM will act as a Ok = 1/16 voltage transformer and create a possible on the low aspect equal to 50V. Present will move by that resistor and is decided by voltage utilized throughout the resistor.

If an vitality supply is added to the low aspect with potential of 51V and replaces the resistor, the potential distinction between the output of BCM (50V) and that vitality supply (51V) will likely be unfavorable (–1V), and the present will begin flowing in the wrong way. The extent of this present will likely be outlined by the full path resistance contained in the BCM and the battery.

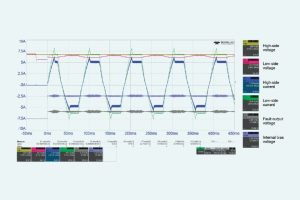

This may be visualized with the BCM linked to 800V supply on the excessive aspect and a bidirectional energy provide on the low aspect. By various the voltage on the bidirectional energy provide ±100mV, present will move alternatively in each instructions, and the height present will likely be 100mV divided by the BCM output resistance. For a bus converter output impedance of 25mΩ, this yields a peak present of roughly 4A flowing bidirectionally below these assumptions (Determine 7).

Determine 7: Oscilloscope display screen seize of bus converter bidirectional present move by various the voltage on the bidirectional energy provide ±100mV, present will move alternatively in each instructions, and the height present will likely be 100mV divided by the BCM output resistance. The bus converter output impedance is likely to be sometimes 25mΩ, so this yields a peak present of roughly 4A flowing bidirectionally below these assumptions.

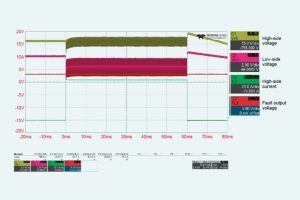

In lab assessments (Determine 8), the BCM6135 has demonstrated peak energy of 4kW (80A at 50V) for 60ms, an indicator that the module design is thermally strong throughout dynamic hundreds.

Determine 8: Oscilloscope display screen seize – 4kW for 60ms. In lab assessments the BCM6135 has demonstrated peak Energy of 4kW (80A at 50V) for 60ms, an indicator that the module design is thermally strong throughout dynamic hundreds.

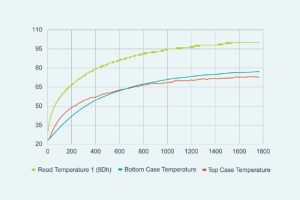

In a second lab check (Determine 9), the load was pulsed from 16A to 80A with a ten% obligation cycle (900ms at 16A and 100ms at 80A). The working situation is 520VHI and 32.5VLO; that is the low finish of the supported BCM6135 voltage vary. The typical energy supply was 720W (22A at 32.5V). Over the course of half-hour (1800s), the inner sensor “learn temperature” (a proxy for junction temperature) indicated a steady-state temperature of ~100°C, significantly beneath the utmost allowable junction temperature of 125°C. The check setup was passive cooling with a single-sided warmth sink. That is one other constructive indicator for the focused passively cooled utility.

Determine 9: 10% obligation cycle 16A to 80A load step with 100°C steady-state learn temperature after 1800 seconds (with single-sided warmth sink).

Alternatively, in a 3rd lab check (see Determine 10), with the identical thermal administration setup, the common energy supply was elevated to 1.1kW (22A at 50V). On this check, the working situation is 800VHI and 50VLO; that is the excessive finish of the supported BCM6135 voltage vary. The load was pulsed from 17.5A to 70A with a ten% obligation cycle (900ms at 17.5A and 100ms at 70A). In 7.5 minutes, the sensed inside temperature was 100°C and was nonetheless rising (not in regular state). However 7.5 minutes (450 seconds) is a for much longer period than 20 seconds, so this can be a constructive indicator that the BCM6135 might meet some energetic suspension design necessities.

Finally, the BCM6135 was lab characterised to help a median energy of 1.3kW for 30 seconds with a passively-cooled warmth sink throughout the sealed-enclosure working temperature vary.

Energetic suspension design goals embody highway floor profile assumptions (amplitude and period of bumps and holes that may be mitigated), and these assumptions bear straight on the required peak energy functionality of the DC-DC converter. The electromagnetic traits of the linear motor additionally influence the DC-DC converter necessities. That mentioned, the BCM6135 is an indispensable bus converter module for modern energetic suspension, energetic anti-roll management DC-DC converter subsystems.

Conclusion

The financial and quality-of-life advantages of electrification is driving the adoption of HV to 48V DC-DC conversion throughout gear sorts all through the worldwide economic system. Built-in high-voltage to 48V energy modules have gotten extra widespread in EVs and HEVs as battery voltages improve and 48V low voltage buses develop into extra widespread.

Subsequent-generation bidirectional fixed-ratio bus converter modules are able to assembly electrically and thermally demanding necessities in transient regenerative use case purposes reminiscent of energetic electrical car suspensions. The passively cooled findings offered are important in gentle of the accelerating pattern in the direction of extra expensive liquid-cooled energy supply programs.