New edge-wound inductors constructed with powdered iron cores provide steady efficiency as much as +180 °C, mushy saturation, and as much as 30% greater present dealing with—boosting effectivity in EVs, hybrids, and high-power automotive methods.

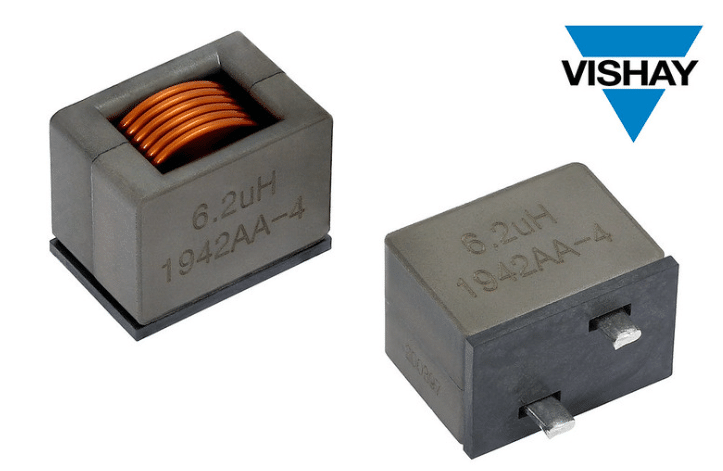

Vishay Intertechnology has launched two new energy inductors that push the boundaries of automotive efficiency. The IHDM-1107BBEV-2A and IHDM-1107BBEV-3A—rugged, edge-wound, through-hole gadgets—are engineered to deal with excessive temperatures as much as +180 °C whereas sustaining steady inductance and mushy saturation. Constructed with powdered iron alloy core expertise, these inductors mark a big improve over typical ferrite-based options.

Designed within the compact 1107 case dimension, these Automotive Grade inductors provide an ultra-low DCR—down to only 0.22 mΩ—which helps reduce energy losses and enhance system effectivity. Their edge-wound coil design improves rated present dealing with, delivering as much as 30% greater saturation and rated present ranges at +125 °C in comparison with ferrite counterparts. The mushy saturation ensures a predictable inductance roll-off as present will increase, no matter temperature—essential for high-reliability automotive energy electronics.

With excessive isolation rankings as much as 350 V and full AEC-Q200 qualification, these inductors are tailor-made for demanding automotive environments. They’re preferrred to be used in DC/DC converters, inverters, on-board chargers (OBC), area management items (DCU), and EMI filters in ICE, HEV, and EV platforms.

The IHDM-1107BBEV household is available in two performance-optimized variants:

- 2A: Inductance from 0.47 to 7.5 µH; saturation present as much as 422 A

- 3A: Inductance from 0.68 to 12.0 µH; saturation present as much as 248 A

Thermal efficiency is powerful, with rated warmth currents reaching as much as 128 A. Floor-mount, press-fit, and naked copper terminal choices can be found on request, alongside customized configurations for inductance, DCR, and voltage score. All fashions are RoHS-compliant, halogen-free, and Vishay Inexperienced, and have hot-dipped tin plating to scale back whisker progress. Manufacturing portions and samples can be found now, with lead occasions of 14 weeks. In a sector that calls for effectivity below strain, the IHDM inductors mix thermal resilience, electrical stability, and customizability—prepared to satisfy the rising energy calls for of electrified mobility.

For extra data, click on right here.