A brand new compact laser displacement sensor redefines short-range measurement with micron-level accuracy, even on darkish, shiny, or irregular surfaces—boosting productiveness and reliability throughout demanding industrial environments.

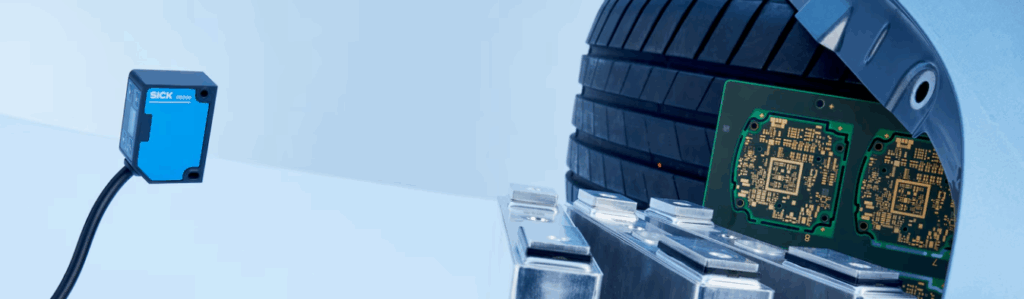

SICK has unveiled the OD200, a compact short-range laser distance sensor engineered for precision measurement in essentially the most demanding industrial environments. Designed with a newly developed triangulation core, high-resolution dynamic receiver system, and an optimized optical setup,it achieves steady, dependable, and repeatable efficiency even on darkish, shiny, or irregular surfaces. The sensor is good for purposes involving reflective supplies corresponding to carbon composites, textured metals, and die castings, the place different sensors usually falter because of poor gentle circumstances or floor inconsistencies.

The important thing options are:

- Measuring vary: 25 mm to 160 mm

- Repeatability: as little as 2 µm

- Excessive-speed efficiency: as much as 3 kHz course of velocity

The core energy lies in its capability to ship excessive measurement accuracy, even in high-speed manufacturing environments. The sensors are perfect for in-line inspection, high quality assurance, and meeting verification throughout industries like automotive, electronics, aerospace, robotics, and client items manufacturing. Its superior optics guarantee dependable detection of low remission or complexly structured surfaces, considerably lowering measurement errors, downtime, and rework.

Ease of integration is a standout characteristic. With a compact design and plug-and-play compatibility, the it matches seamlessly into tight industrial areas. It helps all customary interfaces, together with IO-Hyperlink, analog outputs (present/voltage), and digital I/Os, guaranteeing clean deployment in Business 4.0 environments. An intuitive menu-driven show and SOPAS configuration software program streamline set up, calibration, and diagnostics. IO-Hyperlink additional enhances entry, permitting full management even when sensors are mounted in hard-to-reach areas.

Past simply measuring distance, it contributes to course of optimization. The sensor supplies real-time knowledge like publicity time and sign peak width, enabling customers to watch efficiency and conduct predictive upkeep. This steady suggestions helps forestall unplanned downtime and enhances productiveness.

Nick Hartley, Product Supervisor at SICK, summarizes: “The OD200 presents unmatched measurement stability and ease of integration. With its compact housing, quick response, and talent to sort out even essentially the most troublesome supplies and lighting circumstances, it delivers excessive efficiency and reliability the place different sensors fall brief.”