A compact 50 W thick movie resistor, rated for 50 °C case temperature, provides huge resistance choices and direct heatsink mounting for dependable operation in high-stress automotive and industrial environments.

Assembly the rising want for compact, high-performance passive parts in next-generation autos, Vishay Intertechnology has launched a 50 W thick movie energy resistor designed for direct heatsink mounting and excessive environmental endurance. The system, certified to the AEC-Q200 automotive commonplace, is constructed for high-reliability purposes in electrical and hybrid powertrains the place steady operation beneath stress is essential.

The important thing options are:

- 50 W rated at 50 °C case temperature (heatsink mounted)

- Ceramic factor designed for direct heatsink mounting

- Broad resistance vary from 0.010 Ω to 450 kΩ

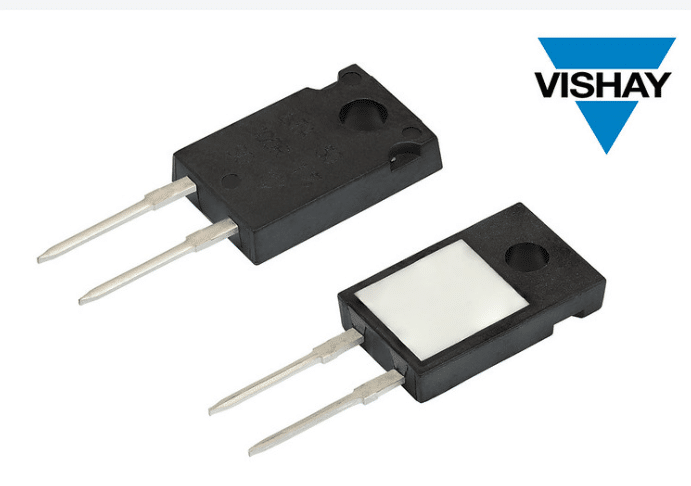

Housed in a TO-220 bundle, the Sfernice LTA 50 withstands temperatures as much as +175 °C whereas sustaining efficiency beneath excessive humidity, vibration, and electrical transients. This rugged design makes it well-suited for safety-critical automotive methods, together with battery administration, motor management, and onboard charging circuits.

The resistor covers a large resistance vary from 0.010 Ω to 450 kΩ, with tight tolerance choices right down to ± 1 %. Its non-inductive development minimizes parasitic results in fast-switching circuits, whereas its excessive dielectric power of 1500 Vrms and limiting factor voltage of 500 V guarantee electrical robustness in high-energy environments.

In sensible use, the LTA 50 can function a pre-charge or discharge resistor in battery administration methods (BMS) or inverter modules, serving to handle inrush currents and shield high-voltage parts in EVs, HEVs, and PHEVs. The system’s compact footprint and direct-mount functionality simplify thermal administration, permitting designers to attain greater energy density with out compromising reliability.RoHS compliance and an environmentally sturdy construct additional improve the half’s suitability for long-life purposes in harsh situations, from under-the-hood electronics to industrial drives and energy provides.

With manufacturing now underway and lead occasions of about 10 weeks, the LTA 50 provides to the corporate’s rising lineup of automotive-qualified passive parts engineered for high-efficiency, high-temperature efficiency within the evolving panorama of electrified mobility.

For extra data, click on right here.