A brand new solvent-based UV patterning approach permits high-resolution 2D semiconductor circuits with out harsh chemical substances or excessive temperatures, providing a sustainable path for next-generation chip fabrication.

Researchers from the Ulsan Nationwide Institute of Science and Know-how (UNIST) and Yonsei College have developed an eco-friendly approach that straight patterns two-dimensional (2D) semiconductors onto substrates—eliminating the necessity for typical high-temperature or chemical etching processes. The strategy might speed up the commercialization of low-power, high-density semiconductor circuits.

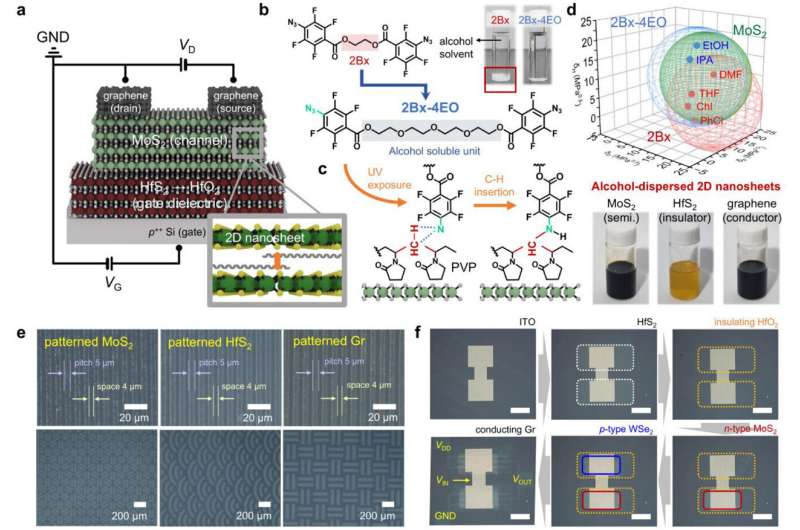

The innovation lies in combining 2D nanomaterials reminiscent of molybdenum disulfide (MoS₂) with a UV-curable cross-linker dispersed in an alcohol-based solvent. Not like conventional fabrication strategies that depend on poisonous natural solvents, this strategy makes use of isopropanol—an environmentally safer different—to exactly outline and solidify circuit patterns utilizing ultraviolet mild. The unreacted materials is just rinsed away with water, forsaking clear, sharply outlined 2D semiconductor buildings.

2D supplies like MoS₂ are prized for his or her atomically skinny, layered construction, which affords superior digital efficiency and power effectivity. Nonetheless, their fragile nature makes them troublesome to course of utilizing typical deposition or etching strategies. The brand new methodology resolves this problem by introducing a room-temperature, solvent-based photopatterning course of that avoids structural injury.

The staff, led by Professor BongSoo Kim of UNIST together with Professors Joohoon Kang and Jeong Ho Cho of Yonsei College, fine-tuned the chemistry of azide-based cross-linkers to make them soluble in isopropanol—one thing beforehand thought inconceivable. This adjustment allowed steady dispersion of 2D supplies and environment friendly UV-induced cross-linking, guaranteeing uniform and reproducible circuit formation.

Efficiency assessments demonstrated the strategy’s technical viability. Fabricated MoS₂ transistors confirmed a cost service mobility of 20.2 cm²/V·s, a threshold voltage of two.0 V, and an on/off ratio of two.7 million. Arrays of 49 transistors maintained steady operation for over 60 days, and the method enabled the creation of each p-type and n-type semiconductor circuits, together with NOT, NAND, NOR gates, and SRAM cells. By extending UV cross-linking know-how—beforehand utilized in quantum dot shows—to 2D supplies, this system marks a essential step towards greener, scalable, and high-precision semiconductor manufacturing.