Heading into 2026, digital transformation is not a distant objective; it’s a each day actuality. It’s outlined by the fast development of sensible belongings throughout the commercial panorama. At its core, being ‘sensible’ means an asset should have the power to speak, which locations the commercial community on the middle of operations. The Cisco Industrial IoT crew is devoted to making sure these connections are safe and resilient, whatever the atmosphere, making your digital journey seamless.

However connecting gadgets is simply half the battle. The true problem is sustaining them and working this infrastructure over time, guaranteeing they continue to be resilient, safe, and environment friendly all through their complete operational lifecycle.

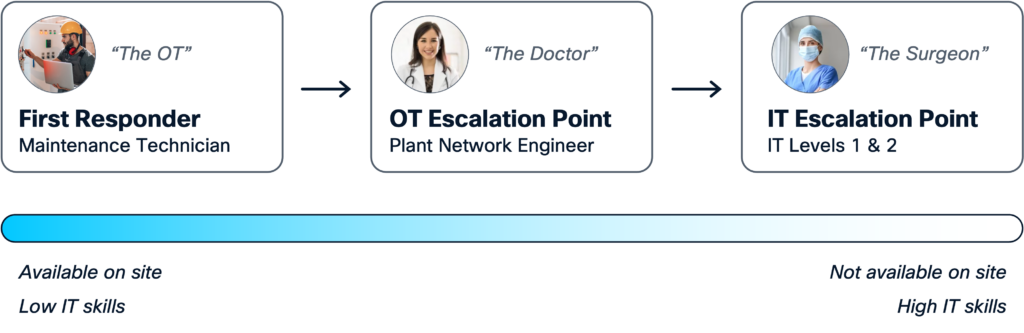

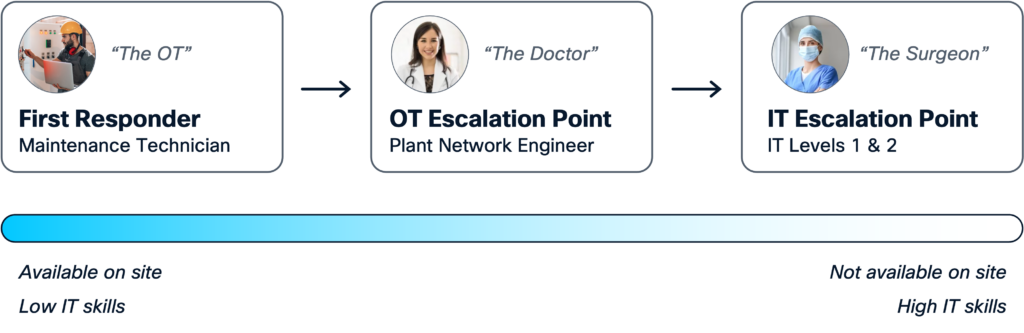

In my conversations with prospects, I’ve seen a typical sample in how industrial websites deal with issues. It’s a three-level escalation mannequin:

- Stage 1: The upkeep technician (the firefighter). They’re on-site 24/7. They’re consultants at mechanical fixes and primary provisioning. Whereas they’re the primary responders with broad information, they typically lack IT or networking experience.

- Stage 2: The plant community engineer (the physician). When the “firefighter” hits a networking wall, they name the “physician.” This particular person has the experience however is never on-shift 24/7, is extra pricey, and will not even be on-site, so that you would want to attend to have any points mounted.

- Stage 3: The IT specialist (the surgeon). If the issue is systemic or extra critical, it goes to the “surgeon.” They’ve the deepest information however are the furthest faraway from the manufacturing facility flooring and as soon as once more, it could possibly take extra time to get the issue mounted.

The objective of our newest innovation is straightforward. We’re specializing in the place a lot of the issues are, utilizing AI to place extra instruments within the upkeep technician’s toolbox. If the “firefighter” can resolve a networking subject on the spot, you don’t have to attend for the “physician,” and your operations get again on-line sooner.

This week at Cisco Stay EMEA, we’re launching AgenticOps for industrial networks, a set of AI-driven capabilities designed to upskill the frontline employee.

- For Manufacturing: The agentic capabilities assist the upkeep technicians establish operational and misconfiguration points in actual time. These capabilities assist technicians establish and root trigger points to maximise community availability. It turns an operational problem right into a step-by-step repair {that a} non-expert can comply with. No want to attend for the physician!

- For Utilities: To maintain the lights on and forestall outages, utilities are constructing ‘smarter’ grids by deploying 1000’s of cellular-connected industrial routers to watch and management energy move remotely. Managing a community unfold throughout a whole territory is a large endeavor, which is why we’ve built-in AI into the Cisco Subject Community Director (FND). Now, operations groups can troubleshoot connectivity and automate deployments at scale while not having to name in a specialist engineer. As an alternative of searching by way of advanced dashboards, you merely ask FND: ‘Which gadgets are offline?’ or ‘How can I optimize mobile utilization?’ These agentic capabilities flip troubleshooting from a frantic race in opposition to alarms right into a guided expertise.

Whether or not you use tens or lots of of websites, holding them operating is essential, however it all begins with guaranteeing they’re safe. However managing safety throughout distributed places is a significant ache level.

To unravel this, we’re introducing Cisco Cyber Imaginative and prescient Website Supervisor. This software acts as a central nervous system on your safety, permitting you to robotically distribute software program upgrades and the most recent risk intelligence to each web site concurrently. It supplies insights to set off alerts when industrial community visitors flows to or from surprising places. It screens the well being of the OT safety infrastructure to make sure each web site is roofed.

Moreover, we’ve launched a brand new Cisco Cyber Imaginative and prescient software for Splunk. This brings OT-specific safety knowledge straight into the fingers of your safety groups, giving them a unified view of the worldwide safety posture with out including software complexity. It simplifies multi-site safety knowledge into customizable dashboards, permitting each plant managers and safety groups to drive actions.

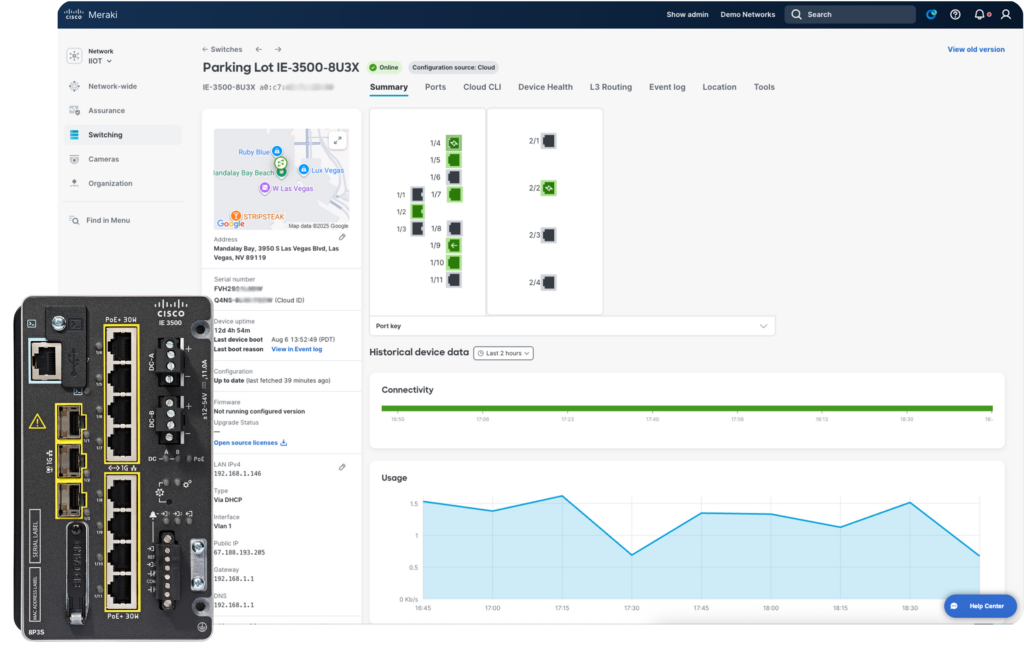

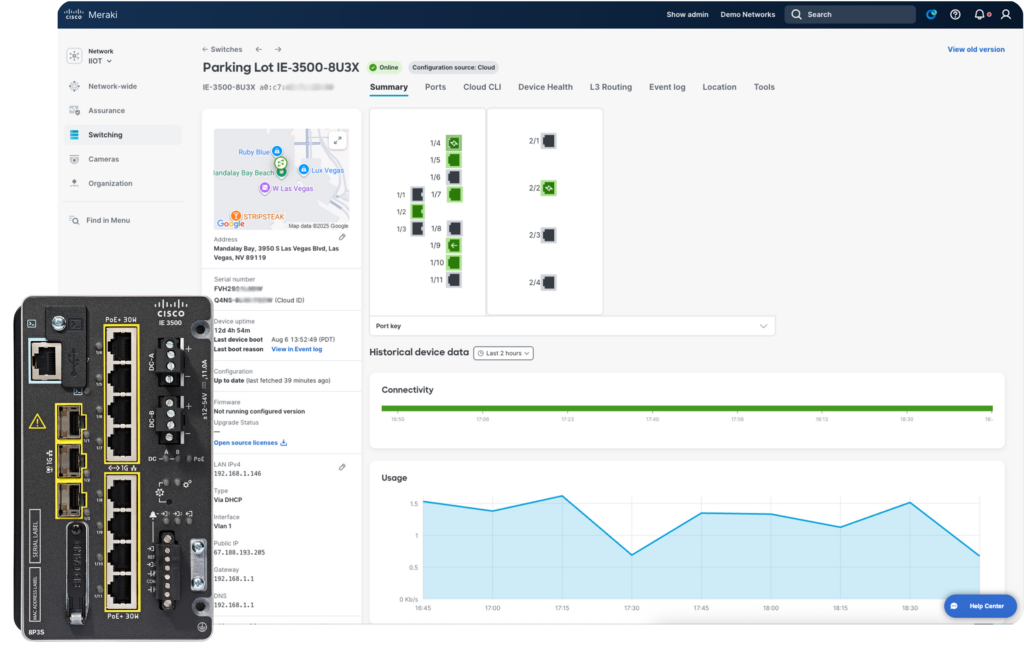

For a lot of of you, the problem is extending your community into areas that aren’t fairly “industrial”, not a manufacturing facility flooring or a utility grid, however not a conventional workplace house both. We name these rugged networks, areas like out of doors areas requiring Wi-Fi, safety cameras, gate entry controls, drive-thrus, charging stations, and even ATMs.

To simplify this, we’re excited to announce cloud administration for Cisco rugged switches, particularly the Cisco IE3500 Rugged Sequence switches. Now, your IT crew can lengthen the enterprise community into difficult bodily environments whereas managing every part from the identical acquainted cloud dashboard. It’s the identical IT expertise you’re keen on, constructed for the robust environments you should attain.

We aren’t simply speaking about these applied sciences; we’re exhibiting them to you in motion. This week at Cisco Stay in Amsterdam, we have now constructed a pallet-sized manufacturing facility that produces Cisco branded hockey pucks within the World of Options.

You may stroll by way of your entire lifecycle of a product:

- Injection molding: the place the puck is fashioned.

- Printing and labeling: the place the branding is utilized.

- Packaging and cargo: the place the product is ready for the actual world.

As you watch the puck transfer by way of the road, you will notice the Cisco IE3100 Heavy Obligation Sequence switches with 90-watt 4PPoE, Cisco IE3500 Rugged Sequence switches operating Cisco Cyber Imaginative and prescient with Safe Gear Entry and our AgenticOps for industrial networks working within the background to maintain the method transferring. You will notice our new Unified Edge server operating digital PLCs to reveal the facility of Software program Outlined Automation. It’s a hands-on have a look at how a related manufacturing facility flooring turns innovation into one thing you may see, comply with, and expertise from begin to end.

Our message this week in Amsterdam is evident: we need to give your frontline industrial groups the arrogance to behave. The groups that see the complete image immediately can act with confidence when it issues most. By empowering the “firefighter” with AI and simplifying multi-site safety, we’re serving to you construct a extra resilient, self-sufficient industrial future.

As we proceed the week right here at Cisco Stay EMEA, I encourage you to see these improvements in motion. Come see the manufacturing facility for your self!