Conrad Nichols, a senior vitality storage expertise analyst at market intelligence agency IDTechEx, previews a number of the key findings from a brand new report.

The Li-ion battery (LIB) recycling market has continued to develop quickly by gamers establishing new partnerships, securing provide offers, and gathering giant volumes of funding. Key gamers have additionally endured with developing new commercial-scale services using mechanical, hydrometallurgical, and pyrometallurgical recycling applied sciences. These applied sciences are properly understood and are more and more getting used at commercial-scale to provide middleman merchandise for brand new Li-ion battery manufacturing, akin to black mass, battery-grade metallic salts, precursor cathode lively materials (pCAM), and CAM.

Nonetheless, these applied sciences wrestle to economically recycle lower-value LFP cathodes. With the rising penetration of this chemistry in electrical automobile (EV) and battery vitality storage system (BESS) markets, the long-term growth of direct Li-ion battery recycling applied sciences will likely be essential, given their proposed manufacturing of cheaper recycled cathode materials. Furthermore, conventional LIB recycling applied sciences have targeted on recovering high-value cathode supplies, akin to lithium, nickel, and cobalt. Recyclers may capitalize on commercializing battery-grade graphite recycling applied sciences to extend the general worth that might be extracted from recycling LIBs. Available in the market report, “Li-ion Battery Recycling Market 2025-2045: Markets, Forecasts, Applied sciences, and Gamers”, IDTechEx forecasts that the Li-ion battery recycling market will likely be valued at US$52B in 2045, primarily based on the worth of supplies that might be extracted from accessible end-of-life (EOL) LIBs and manufacturing scrap. Importantly, nevertheless, continued innovation and developments in direct LIB recycling and battery-grade graphite recycling applied sciences will likely be wanted for this full worth to be captured.

Advances in direct Li-ion battery recycling applied sciences: industrial exercise, challenges, and prospects

It’s extensively identified that LIBs adopting ternary chemistries akin to NMC (nickel manganese cobalt oxide) are extra worthwhile to recycle than LFP chemistries because of the inclusion of nickel and cobalt within the cathode. Nonetheless, LFP chemistry demand is rising inside each EV and BESS markets, the place prioritizations on value, security, and cycle life could also be seen relying on the applying. Subsequently, strain is beginning to mount for the event of extra financial recycling applied sciences, which might enormously profit LFP recycling. Specifically, this might embrace direct LIB recycling applied sciences.

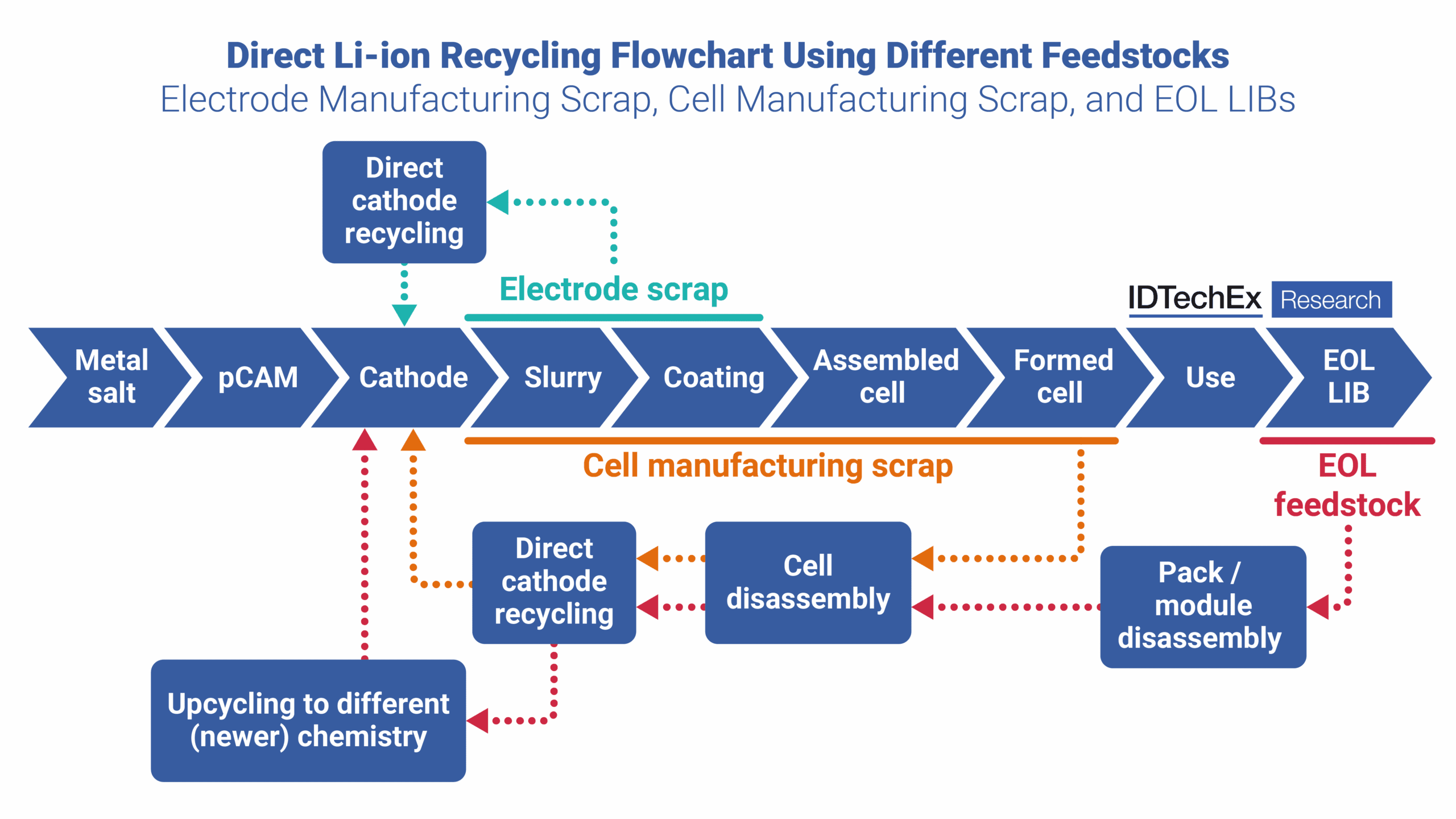

Direct recycling includes reactivating the battery materials to get well capability misplaced throughout biking. Not like pyro- and hydrometallurgical strategies, the crystal construction of Li-ion cathodes is prevented from being damaged down. If the CAM is repairable, it may be relithiated through a spread of strategies, together with thermal, hydrothermal, and electrochemical processes.

Direct recycling applied sciences being developed may supply a less expensive different to conventional LIB recycling applied sciences. These claims are being steered by a number of key gamers, as investigated within the new report. A number of of those gamers are additionally in pilot levels of direct LIB recycling expertise growth, with just a few near commencing industrial operation of their first direct LIB recycling plant.

Whereas direct LIB recycling proposes a less expensive resolution, two key challenges embrace demonstrating efficiency over prolonged biking (>1000 cycles) with minimal capability fade, and upcycling chemistries to fulfill new market demand. If an EOL LIB is used because the direct recycling feedstock, this may doubtless should be upcycled to a more moderen chemistry because the feedstock will lag demand for brand new, doubtlessly increased efficiency, chemistries. Upcycling is subsequently doubtless so as to add to course of value, attributable to further processing and doubtlessly added course of vitality depth, decreasing the industrial viability of the expertise.

Nonetheless, LIB cell manufacturing scrap coming from totally different factors within the cell manufacturing course of will even be a key feedstock for direct LIB recycling. Electrode scrap, together with assembled and fashioned cells can all kind elements of cell manufacturing scrap feedstock. Since this feedstock is made accessible throughout ongoing cell manufacturing, this chemistry won’t require upcycling. This may increasingly subsequently see this feedstock turn into favoured for direct recycling applied sciences within the medium time period, which might be additionally helpful for the uptick in LFP adoption being noticed in present EV and BESS markets. Nonetheless, with the nice majority of LFP cell manufacturing occurring in China, this area of interest profit is just more likely to be realized by Chinese language LIB recyclers within the medium-term.

No matter feedstock, if upcycling course of prices might be minimized, and prolonged biking efficiency of recycled cathodes might be demonstrated, direct recycling applied sciences may trigger a a lot larger shift in each LIB recycling and virgin cathode manufacturing markets in the long run.

Rising exercise of battery-grade graphite recycling expertise growth for Li-ion

Business restoration and recycling of graphite from Li-ion batteries (LIBs) is restricted because of the comparatively decrease worth of graphite in comparison with increased worth cathode supplies, and because of the problem of recycling graphite again to a product with battery-grade purity (>99.95%). Nonetheless, the rising recognition of LFP, makes an attempt for extra localised provide chains, ongoing reliance on China for battery graphite provides, and continued development in graphite anode demand, alongside rising strain for a extra round Li-ion battery trade, has all began to place give attention to the recycling of graphite from LIBs.

A number of key gamers want to commercialize battery-grade graphite recycling applied sciences. This consists of Li-ion recycling gamers akin to American Battery Know-how Firm (ABTC), Ascend Parts, and Cylib. Key gamers targeted on graphite recycling embrace Inexperienced Graphite Applied sciences, EcoGraf, Graphite One, and X-BATT. A few of these gamers are claiming that their recycled graphite is, or near, battery-grade, and a few are in levels of verifying anodes utilizing recycled graphite in checks with clients (e.g., EV battery producers). Whereas these preliminary checks look promising, recycled graphite purity and anode efficiency over prolonged biking (>1000 cycles) have to be demonstrated to advertise the industrial viability of those recycling applied sciences.

Crucially, given the decrease worth of graphite in comparison with different crucial battery supplies, the strategies used to purify and get well recycled graphite will even should be carried out at low value to make sure the financial viability of battery-grade graphite recycling applied sciences.

Li-ion battery recycling expertise outlook

Conventional LIB recycling applied sciences, together with mechanical, hydrometallurgical, and pyrometallurgical processes, are commercially accessible, properly understood, and capacities for these applied sciences are increasing globally. Nonetheless, growing direct recycling and battery-grade graphite recycling applied sciences may assist LIB recyclers notice improved profitability. These applied sciences may additionally permit for the extra financial recycling of LFP Li-ion batteries. If each the efficiency of anodes utilizing recycled graphite and the efficiency of immediately recycled cathodes might be proven to not be considerably worse than their virgin counterparts, and course of prices might be saved low, these prospects may turn into a extra widespread actuality within the long-term. Each applied sciences proceed to bear growth, with some direct LIB recyclers trying to quickly fee their first commercial-scale plant.

For extra info on this report go to www.IDTechEx.com/LIRecycling.