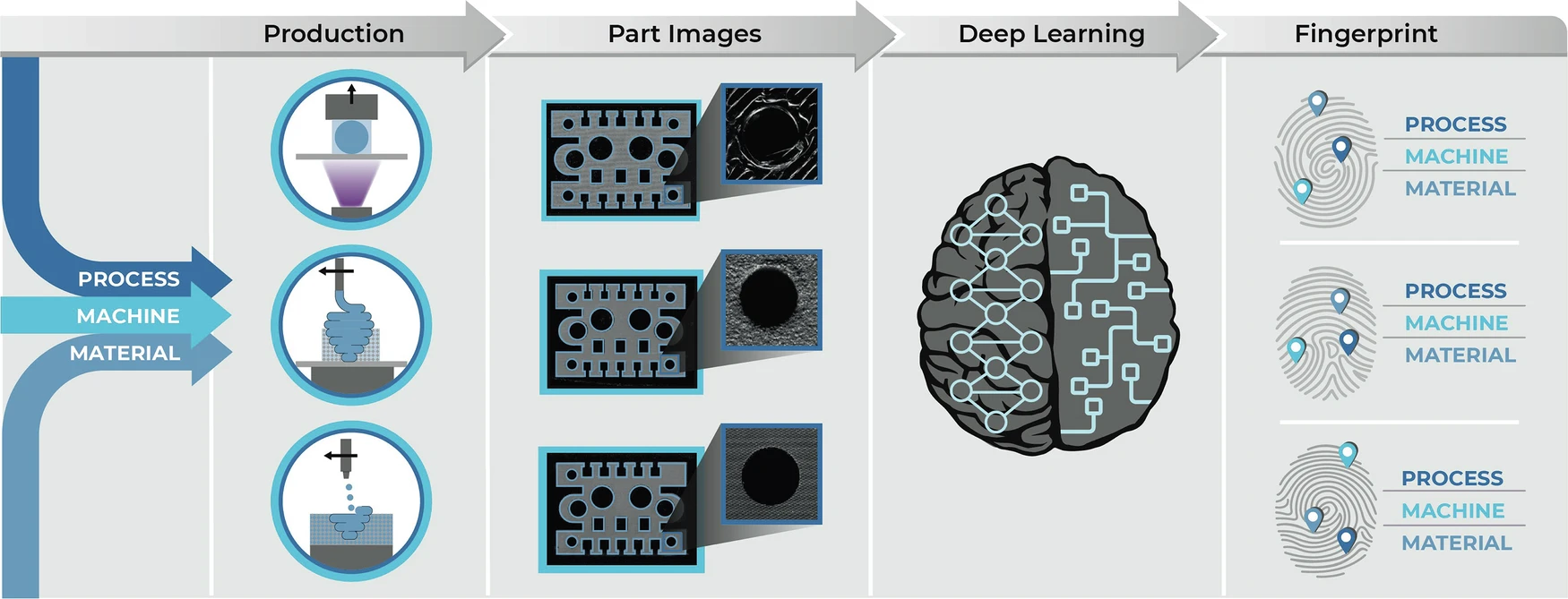

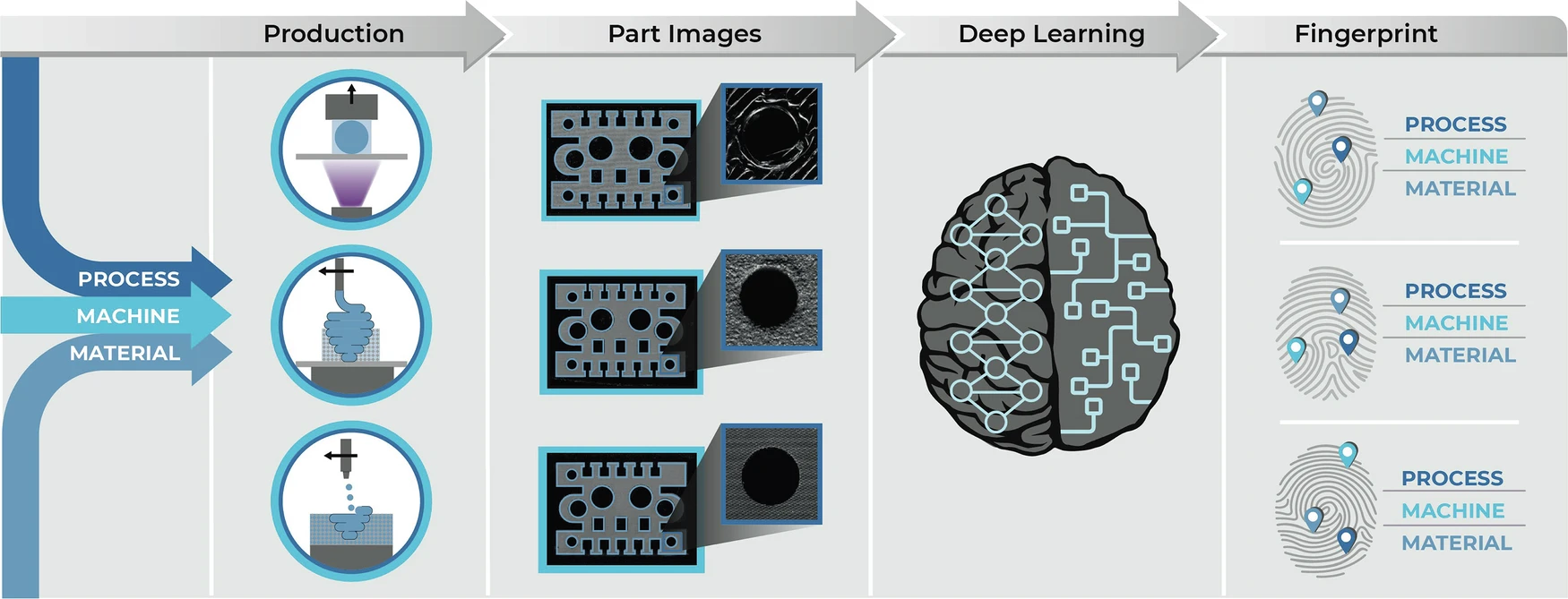

Researchers from the College of Illinois Urbana-Champaign have developed a brand new methodology for figuring out the supply of 3D printed components utilizing high-resolution pictures and deep studying. The strategy analyzes manufacturing fingerprints – distinctive bodily traits embedded in components throughout manufacturing – to find out which printer created a part. This expertise addresses important challenges in manufacturing provide chains, the place monitoring components throughout a number of suppliers has historically been troublesome.

The examine examined this identification methodology on 9,192 components produced from 21 totally different sources, utilizing three distinctive designs and 6 supplies. Researchers achieved over 98% accuracy in figuring out the supply printer. The system may additionally decide the manufacturing course of, materials kind, and particular location the place the half was printed throughout the machine.

Not like earlier analysis that targeted totally on consumer-grade desktop printers, this examine focused industrial additive manufacturing gear utilized in manufacturing environments. 4 kinds of AM gear and 7 totally different printer fashions have been included within the testing. The strategy proved efficient throughout various supplies and half designs.

Conventional half identification strategies like labels, RFID tags, or laser engravings will be simply compromised or eliminated. By analyzing inherent bodily attributes created throughout manufacturing, this deep studying strategy affords a safer different. The system can determine patterns which are undetectable to human inspectors.

Manufacturing supply identification has important purposes for high quality management, defect identification, provide chain administration, and authenticity verification. This turns into notably useful in additive manufacturing, the place distributed provide chains pose distinctive challenges. The expertise gives a brand new device for validating supplies, processes, and accomplished components in complicated manufacturing networks.

Supply: nature.com