US-based biotechnology firm Continuity Biosciences has invested in 3D printed microneedle know-how specialist PinPrint to broaden its focus from therapeutic supply into aesthetic and beauty purposes.

Designed to ship vaccines and lively brokers intradermally, PinPrint’s microneedle patches provide a possible different to conventional injections. With this funding, Continuity goals to boost its capabilities within the drug supply sector. The corporate can also be working with the Grattoni Lab at Houston Methodist Hospital to develop implanted nanofluidic platforms for prolonged, zero-order launch.

Moreover, Dr. Venugopalan is about to hitch PinPrint’s Board of Administrators (BoD). “This funding permits us to broaden from implanted nanofluidic methods to a non-implanted microfluidic platform,” mentioned Ramakrishna Venugopalan, PhD, Co-Founder and CEO of Continuity Biosciences.

“It opens up new potentialities for simpler supply of dermatologic, aesthetic, and beauty brokers instantly into the dermis,” Venugopalan mentioned.

Over-curing drawback solved with iCLIP

PinPrint was co-founded by Dr. Joseph DeSimone, Co-founder and former CEO of California-based 3D printer producer Carbon. Alongside Stanford College researchers, DeSimone developed a 3D printing technique that addresses resin over-curing, a problem that hinders the exact building of microchannels and voids in medical gadgets like microfluidic-backed microneedles.

The know-how behind PinPrint’s method relies on this resin 3D printing course of. Final yr, their analysis was revealed in Proceedings of the Nationwide Academy of Sciences (PNAS) journal, introducing the injection CLIP (iCLIP) technique.

iCLIP improves the decision and precision of 3D printed microfluidic gadgets by constantly feeding contemporary resin into destructive areas throughout printing, stopping over-curing and making certain a extra correct construction.

Not like conventional 3D printing strategies, which wrestle with over-curing that may distort the printed channels, iCLIP ensures that contemporary resin fills these areas, sustaining each the integrity and precision of the print. This capacity to regulate resin circulate results in the creation of microchannels with smaller diameters and heights, enhancing the performance of printed gadgets.

The iCLIP strategies is particularly priceless in purposes requiring excessive precision, corresponding to drug supply and biomedical gadgets. For instance, its microneedle patches goal to enhance the supply of vaccines and therapeutic brokers.

The iCLIP technique permits PinPrint to supply smaller, extra correct gadgets, bettering the supply of remedies whereas providing non-invasive options to conventional injection strategies.

Past microneedles, the iCLIP technique has broad potential purposes in areas like vascular networks, microarrays, and diagnostic gadgets. PinPrint is working to broaden its portfolio of merchandise utilizing iCLIP, with a deal with biomedical and pharmaceutical makes use of. This technique guarantees extra environment friendly drug supply methods, offering options to present strategies.

“By integrating high-resolution 3D printing with superior drug supply, we’re redefining the affected person expertise throughout therapeutic and beauty classes—providing a brand new customary for precision, personalization, and luxury,” mentioned Dr. DeSimone, at present Sanjiv Sam Gambhir Professor of Translational Medication and Chemical Engineering at Stanford.

Increasing microfluidic capabilities

Whereas PinPrint advances resin 3D printing for biomedical use, different corporations are additionally tackling microfluidic manufacturing challenges by complementary approaches.

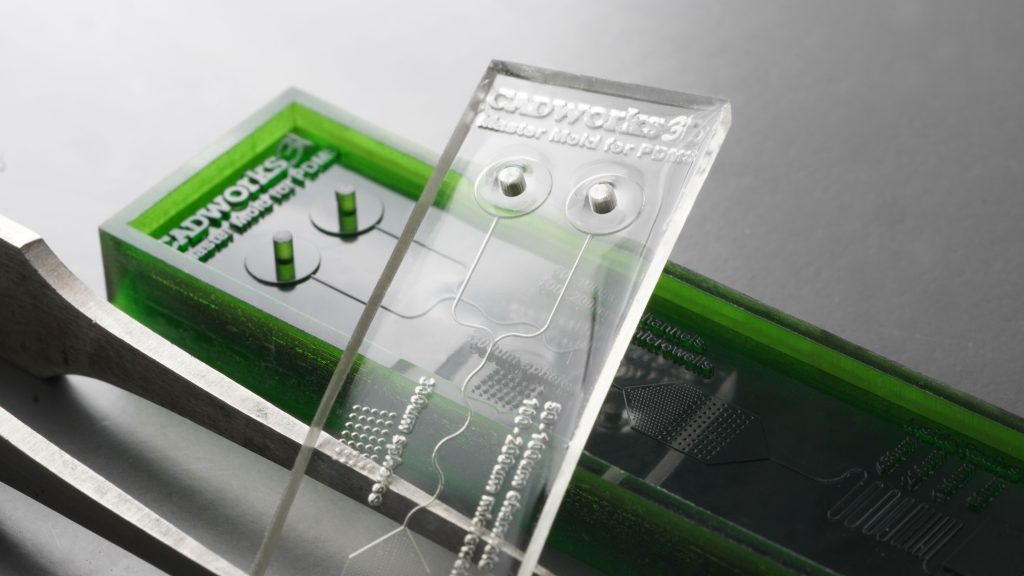

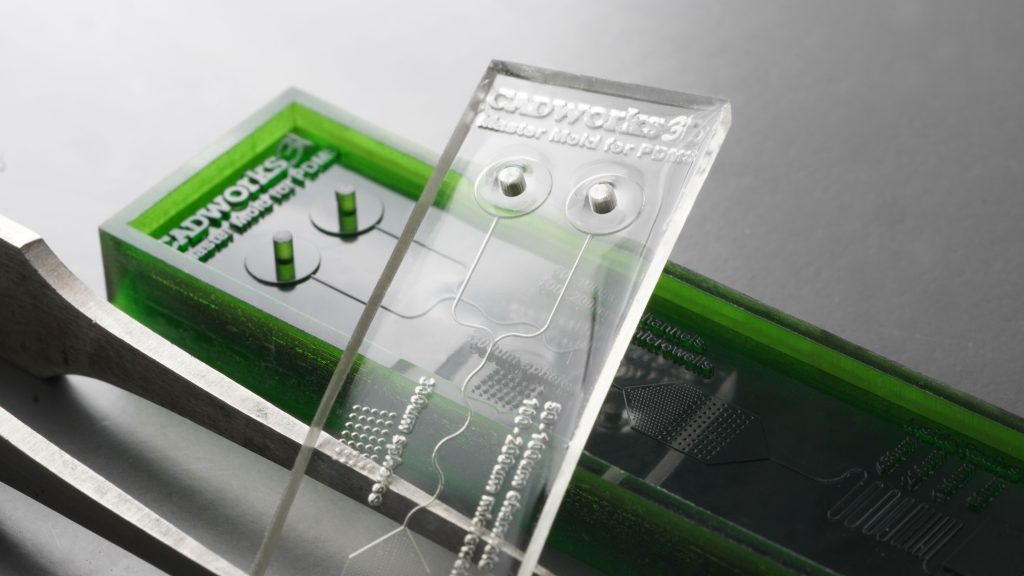

In 2023, Canadian 3D printer producer CADworks3D launched a singular strategy to fabricating PDMS gadgets for microfluidic purposes. Having built-in 3D printing with specialised photopolymer supplies, the corporate has created a extra environment friendly course of for producing high-precision microfluidic gadgets.

With its ProFluidics 285D Digital Mild Processing (DLP) 3D printer and Grasp Mildew for PDMS System resin, CADworks3D permits researchers the flexibility to shortly prototype and customise advanced microstructures. This improvement enhances the delicate lithography workflow, decreasing manufacturing time and prices whereas delivering superior machine options. The result’s a quicker, extra accessible technique for creating tailor-made microfluidic options.

By way of software program, Microlight3D and Eden Tech goal to supply superior microfluidic design instruments for the healthcare, diagnostics, and analysis sectors. Combining Microlight3D’s Sensible Print UV with Eden Tech’s FLUI’DEVICE design platform, this transfer is alleged to cut back design cycles, slicing them by as much as 90% in comparison with conventional CAD strategies.

The brand new answer enhances the accessibility, customization, and scalability of microfluidic gadgets. It permits faster design iterations, lowers manufacturing prices, and ensures easy integration with manufacturing methods. This partnership affords a novel device for each tutorial and industrial customers, streamlining workflows and accelerating time-to-market.

What 3D printing developments must you be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals microfluidic enabled microneedle patch. Picture by way of PNAS.