A low-temperature methodology to create safer, high-performance solid-state batteries, probably reworking vitality storage in all the pieces from smartphones to electrical automobiles.

In a promising leap for next-gen vitality storage, researchers at Penn State are advancing solid-state battery know-how that might substitute the normal—and infrequently hazardous—lithium-ion batteries present in telephones, laptops, and electrical automobiles.

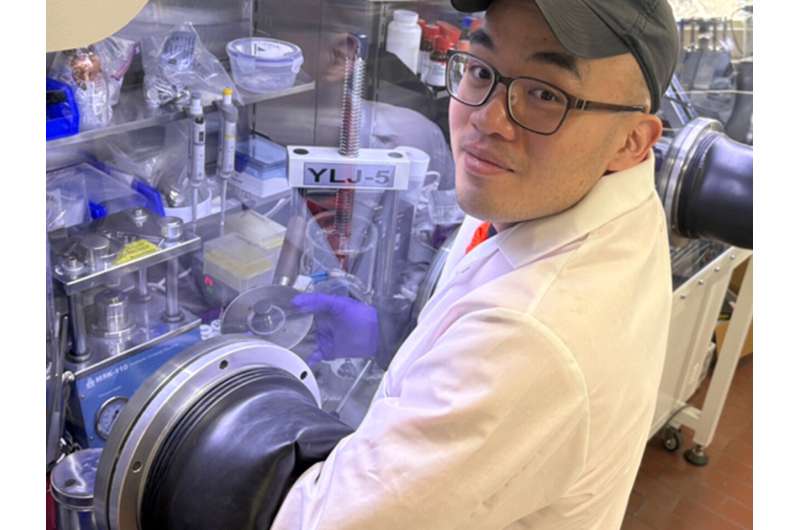

The staff, led by Hongtao Solar, assistant professor of business and manufacturing engineering, is specializing in solid-state electrolytes (SSEs), which substitute the flammable liquid electrolytes in typical batteries. SSEs provide superior thermal stability and security, however traditionally, they’ve been troublesome to provide resulting from excessive processing temperatures and poor conductivity.

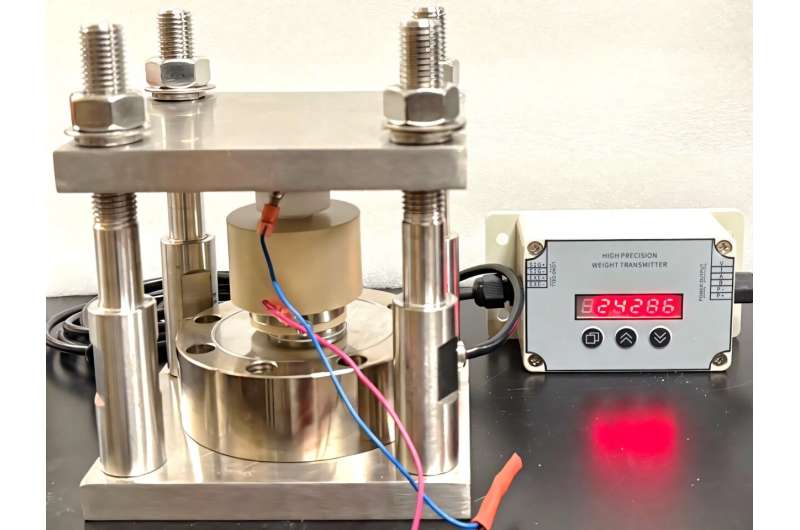

To resolve this, Solar’s staff employed a method generally known as chilly sintering—a low-temperature course of that compresses ceramic powders into dense kinds utilizing stress and a small quantity of solvent. This methodology allowed the researchers to create a brand new ceramic-polymer composite SSE known as LATP-PILG, combining the excessive conductivity of a poly-ionic liquid gel (PILG) with the steadiness of ceramic LATP. “Conventional sintering requires temperatures close to 1,000°C,” Solar defined, “however chilly sintering lets us maintain it to round 150°C. That’s low sufficient to protect the polymer parts whereas densifying the ceramic.”

A significant innovation lies in how the staff tackled ion transport points. Usually, grain boundaries in ceramic supplies impede conductivity. However by integrating PILG into the grain boundaries, they created engineered pathways that improve ionic motion and cut back vitality loss. The ensuing composite SSE not solely boasts excessive room-temperature conductivity, but in addition helps a wider voltage window (0 to five.5 volts), in comparison with the 0 to 4 volts typical of liquid electrolytes. This implies the batteries can use high-voltage cathodes and ship extra vitality.

Trying forward, Solar envisions broad functions for chilly sintering past batteries—into semiconductor manufacturing and normal ceramics processing. “Our subsequent step is creating a sustainable, scalable manufacturing mannequin,” he stated. “That’s the place the way forward for this know-how lies.”