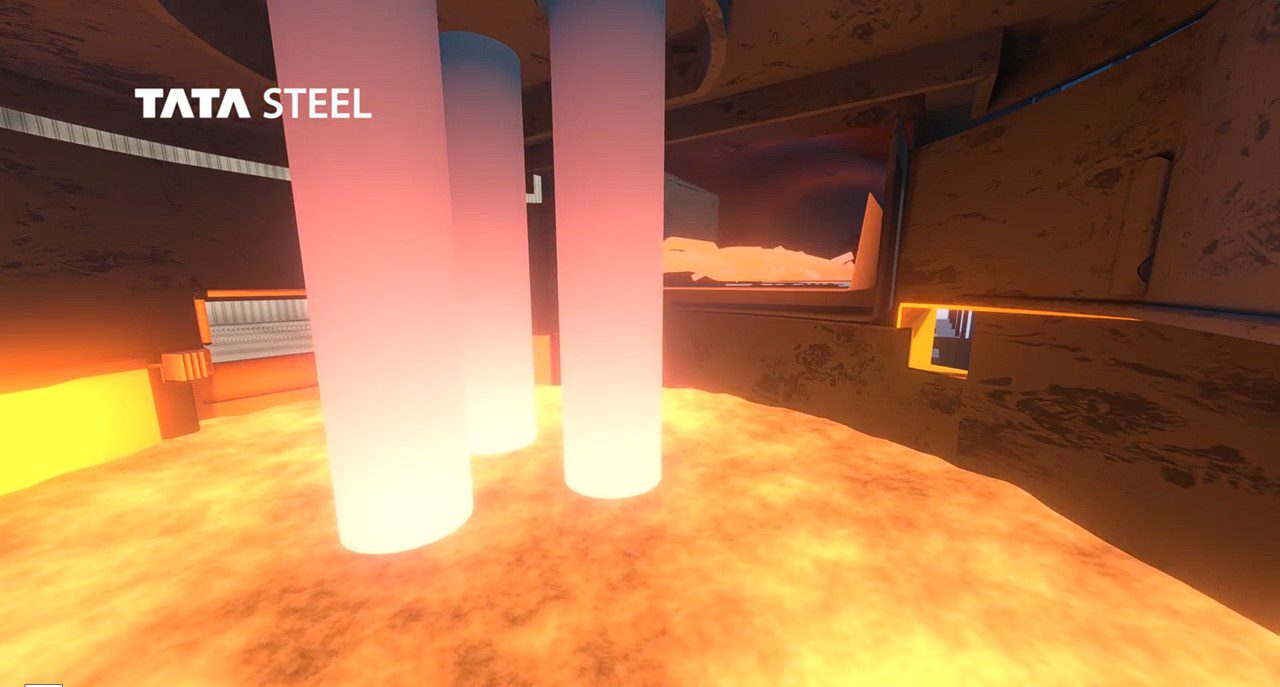

Development has begun on Tata Metal UK’s Electrical Arc Furnace (EAF) facility in Port Talbot, stated to be the UK’s largest low-carbon steelmaking facility.

At a ground-breaking ceremony on Monday 14 July, the group’s chairman, Natarajan Chandrasekaran, marked the opening of this new part within the mission, described by Enterprise Secretary Jonathan Reynolds as “nice information for Welsh steelmaking”.

The UK authorities has dedicated £500 million in the direction of an total £1.25 billion funding by the group in efforts to modernize and decarbonize its UK operations, a transition to low-CO2 steelmaking that features development of the brand new EAF, the decommissioning of two getting old blast furnaces and coke ovens, and the availability of further supporting infrastructure, coaching and different preparations for lower-emissions operations.

In some analyses, electrical Arc Furnaces can reduce CO₂ emissions by as much as 80–90% in comparison with conventional blast furnace–primary oxygen furnace (BF‑BOF) steelmaking, particularly if powered by renewable electrical energy.1

Tata Metal UK stated the brand new EAF — set to be commissioned on the finish of 2027 — is anticipated to scale back Port Talbot’s carbon emissions by roughly 90%, equal to five million tonnes of CO₂ per 12 months, whereas securing high-quality sustainable metal manufacturing and supporting 5,000 UK jobs instantly.

Talking forward of the ceremony, Mr Chandrasekaran stated the ground-breaking marked “the start of… a brand new period for sustainable manufacturing in Britain”.

The Port Talbot EAF might be one of many largest on the planet, melting UK-sourced scrap metal to provide 3 million tonnes of metal per 12 months. As a part of Tata Metal UK’s broader decarbonisation technique, the mission additionally contains new ladle metallurgy amenities, infrastructure upgrades, and partnerships with main know-how suppliers comparable to Tenova, ABB, and Clecim.

Development is being led by foremost contractor Sir Robert McAlpine, alongside a regional provide chain that features Darlow Lloyd & Sons, Mii, Skelton Thomas, Wernick Buildings, Andrew Scott Ltd and Programs Group.

Secretary of State for Wales Jo Stevens stated:

“The UK Authorities acted decisively to make sure that steelmaking in Port Talbot will proceed for generations to come back, backing Tata Metal with £500 million to safe its future within the city, together with £80 million to assist staff and the broader group. Our Metal Technique can even ship £2.5 billion of funding to rebuild the UK business, preserve jobs and drive development.

“The development of Tata’ s new furnace realises the promise we made to the group, whereas the event of floating offshore wind, plans for a Celtic Freeport and thousands and thousands extra for native regeneration all imply that Port Talbot has a vivid future.”

First Minister Eluned Morgan stated:

“This can be a momentous day for heavy business in Wales, as the electrical arc furnace has secured the long-term way forward for metal making at Port Talbot. Seeing spades within the floor in the present day gives a tangible signal of Tata’s intention to proceed producing metal within the space, an business which has offered high quality jobs to native folks for generations.

“The beginning of the development part is nice information for Port Talbot and neighbouring communities, and I’m particularly happy that Tata has dedicated to using native contractors and native staff the place it could actually.”

Notes

[1] “Low-carbon manufacturing of iron and metal: Know-how choices, financial evaluation, and coverage”, Joule, April 2021. https://www.cell.com/joule/fulltext/S2542-4351percent2821percent2900095-7?utm_source=chatgpt.com