Dalhousie College has partnered with Defence Analysis and Growth Canada (DRDC) to handle crucial elements provide challenges for Canada’s ageing submarine fleet. The collaboration focuses on creating additive manufacturing processes for naval parts as Canada prepares to switch its Victoria-class submarines, that are scheduled for decommission within the mid-2030s. Till new submarines arrive, anticipated round 2035, sustaining the present fleet stays important for navy readiness.

The challenge tackles a big logistical downside: sourcing substitute elements for decades-old submarines when authentic producers might not exist. Cameron Munro, a defence scientist with DRDC at Halifax’s Atlantic Analysis Centre, explains the present scenario: “If you must change an element on a submarine that was constructed 35 years in the past, you could discover that the producer not exists.” Conventional procurement strategies for customized parts can take years, creating delays that affect operational readiness.

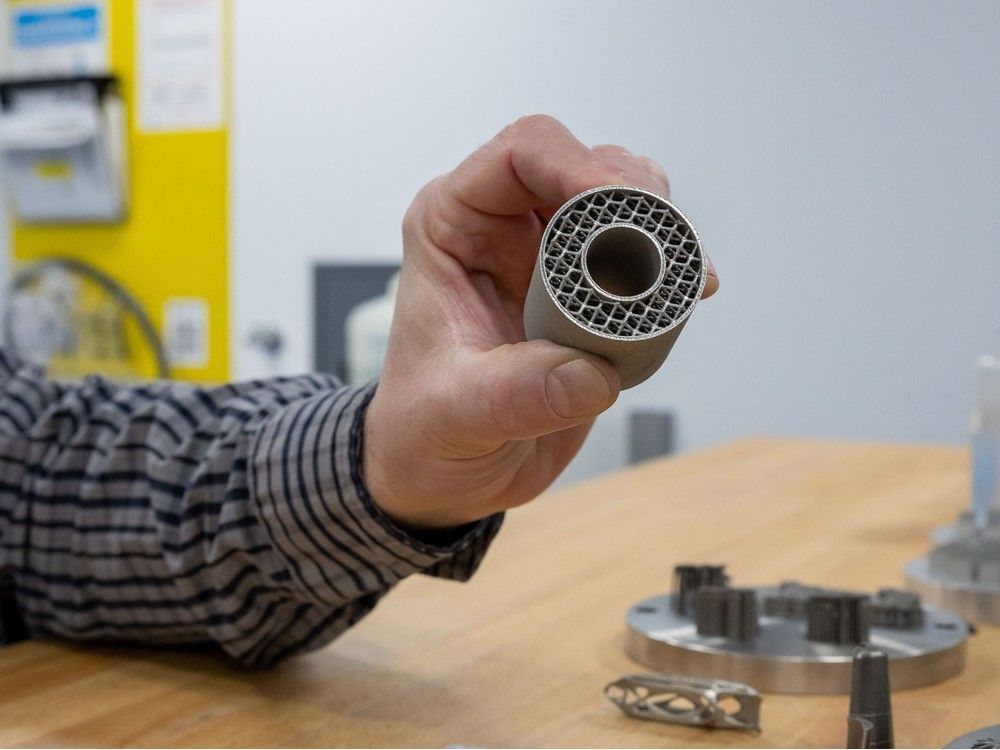

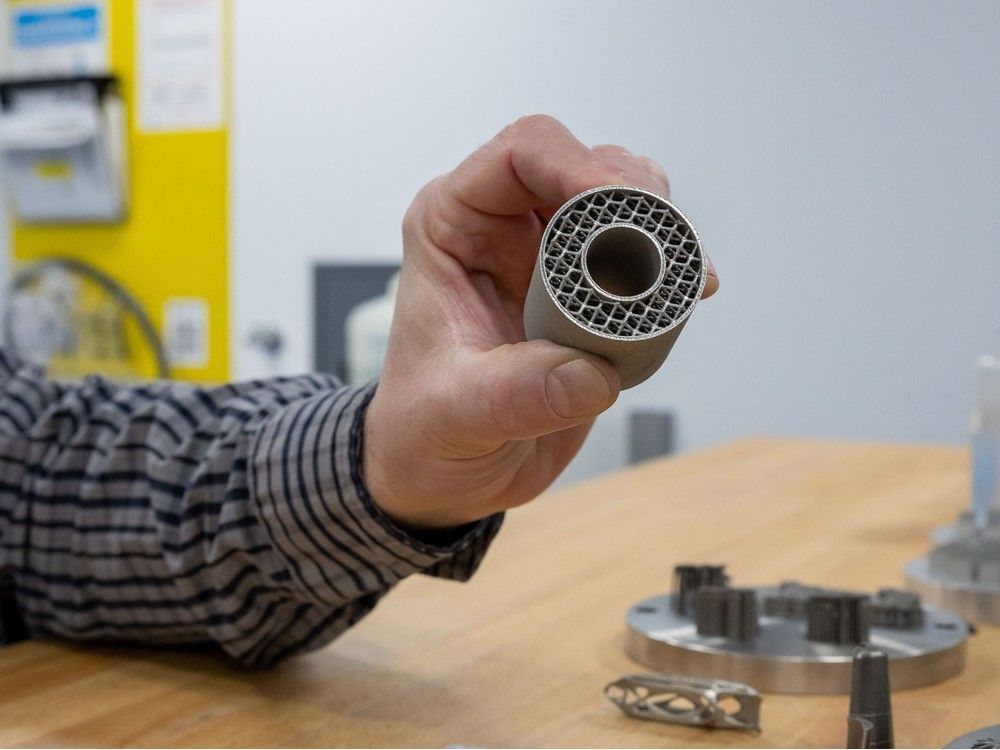

Supplies engineer Dr. Paul Bishop is main the analysis at Dalhousie, using specialised 3D printing methods to manufacture steel parts straight from powders. “Dalhousie has designed and commissioned an exceptionally complete suite of infrastructure for this know-how — globally aggressive and nationally distinctive,” says Dr. Bishop. The college’s analysis group is pioneering work with defense-standard naval alloys which have by no means earlier than been studied for additive manufacturing purposes.

The partnership positions Dalhousie as an middleman between DRDC and Canadian producers. By creating basic “recipes” for supplies and processing parameters, the college creates specs that firms can implement with out intensive analysis funding. This method permits the Royal Canadian Navy to keep up possession of the analysis and keep away from dependency on single suppliers for crucial parts.

In line with Munro, the challenge extends past fast wants: “This challenge isn’t nearly making one or two parts — it’s about constructing long-term industrial capability in Canada.” The initiative goals to allow on-demand manufacturing of elements quite than sustaining massive inventories, doubtlessly decreasing prices whereas guaranteeing availability. The analysis is supported by NSERC, the Canadian Basis for Innovation, and trade companions.

Dr. Bishop emphasizes the data switch side of the collaboration: “The true objective is to supply the Navy and the supporting trade companions with knowledge that outline dependable processes that can be utilized at scale.” This method helps better self-reliance in sustaining Canada’s naval capabilities, with Munro noting, “We have to enhance our skill to assist Canada’s navy platforms domestically.”

Supply: dal.ca