Safe your spot now for unique AM insights at our Additive Manufacturing Benefit on-line convention protecting aerospace, house, and protection.

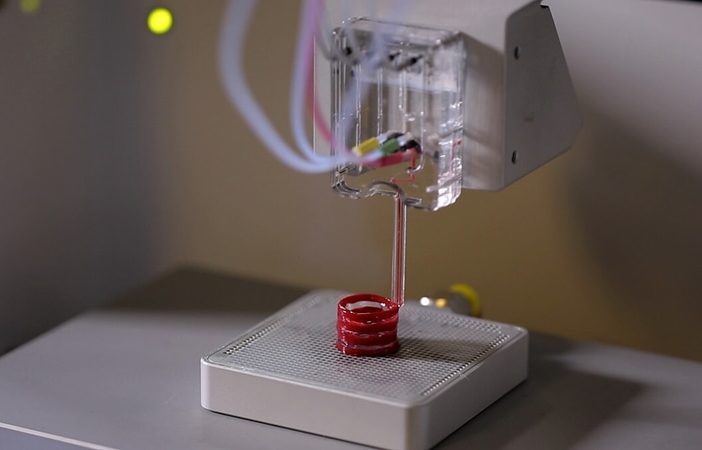

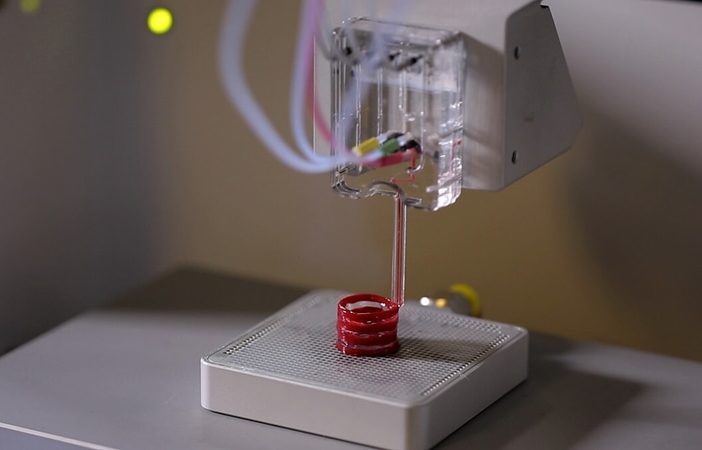

Researchers at Wake Forest College and College of Miami have developed a technique to 3D print insulin-producing human islets utilizing a bioink comprised of alginate and decellularized pancreatic tissue. The work was offered on the ESOT Congress 2025.

Printed in bioRxiv, and led by Dr. Quentin Perrier of Wake Forest College College of Medication, the staff constructed dense islet clusters that preserved their form and performance over time. In contrast to present islet transplant methods that ship cells into the liver and face excessive failure charges, this strategy is meant for implantation beneath the pores and skin.

The surgical necessities are minimal and contain solely a neighborhood anesthetic and a small incision, which may make the process simpler to tolerate and extra constant in final result. Notably, their printed constructs remained alive and attentive to glucose for 3 weeks, demonstrating the feasibility of utilizing 3D printing to provide purposeful islets for future implantation in kind 1 diabetes remedy.

“Our aim was to recreate the pure atmosphere of the pancreas in order that transplanted cells would survive and performance higher,” Dr. Perrier informed MedicalXpress.

Towards skin-implanted diabetes remedy

To make sure the islets would survive the printing course of, the researchers decreased the stress utilized to the cells by adjusting mechanical settings. They printed at a stress of 30 kPa and a velocity of 20 mm/min, situations that helped shield the structural integrity of the fragile clusters.

Publish-printing exams confirmed that greater than 90% of the cells remained viable and that the islets persistently responded to glucose by releasing insulin. The quantity of insulin produced exceeded that of typical islet preparations, indicating a excessive stage of retained perform.

The printed islets have been designed with inner porosity that allowed vitamins and oxygen to maneuver effectively all through the construction. This characteristic helped keep cell viability and supported the form of tissue integration wanted for long-term perform after implantation. The improved move situations additionally inspired early blood vessel formation, which is important for the survival of implanted cell clusters.

All through the 21-day commentary interval, the constructions maintained their form and performance. They didn’t clump or collapse, issues which have affected earlier efforts to provide comparable constructs. The staff believes that utilizing precise human islets, reasonably than animal-derived cells, marks a step ahead in creating therapies that may translate extra immediately into medical settings.

Ongoing experiments contain testing the printed islets in animal fashions to know how they behave after implantation. The researchers are additionally evaluating storage methods, together with cryopreservation, to find out how the printed tissues will be preserved and transported.

As well as, they’re working to adapt the method to different sources of insulin-producing cells, together with these derived from stem cells and porcine donors.

Though the strategy continues to be in early levels of growth, it presents a potential different to every day insulin remedy. Additional analysis might be required to evaluate how nicely the printed islets carry out in dwelling methods, and “if medical trials verify its effectiveness, it may remodel remedy and high quality of life for tens of millions of individuals worldwide,” stated the lead writer.

Bettering diabetes care

3D printing is rapidly changing into a robust device in reshaping how we deal with, and monitor diabetes making care extra customized and constructed to final.

Again in 2022, Canadian 3D bioprinting agency Side Biosystems partnered with JDRF to develop a 3D bioprinted tissue remedy aimed toward treating kind 1 diabetes. The aim was to create a cell-based implant that restores insulin manufacturing, probably eliminating the necessity for every day injections.

With JDRF offering each funding and many years of analysis experience, the partnership was anticipated to speed up progress towards human trials. Whereas particular particulars of the remedy remained beneath wraps, it centered on repairing pancreatic perform by way of engineered tissue, providing a promising path towards a extra lasting and much less invasive remedy for kind 1 diabetes.

In India, BITS Hyderabad researchers developed a low-cost, non-invasive machine to watch diabetes by analyzing glucose and lactate ranges in sweat. Utilizing 3D printing, CO₂ laser expertise, and graphene electrodes extracted in-house, the staff created a conveyable sensor that operated on electrochemiluminescence, emitting mild in response to chemical reactions triggered by sweat.

The depth of this mild was used to measure lactate focus, with machine studying bettering the precision of the readings. Designed to attach with smartphones by way of an app, the machine was additionally being tailored right into a wearable format, with business rollout focused inside 6 to 9 months on the time of reporting.

What 3D printing developments do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits the printed assemble with 10,000 IEQ/mL of HI bioink. Picture by way of Wake Forest College.