April twenty second is Earth Day – a strong reminder of our shared duty to protect the planet for future generations. Whereas the decision for local weather motion grows louder, Arduino is dedicated to making sustainability an ongoing precedence by means of concrete initiatives and international collaborations day-after-day of the yr.

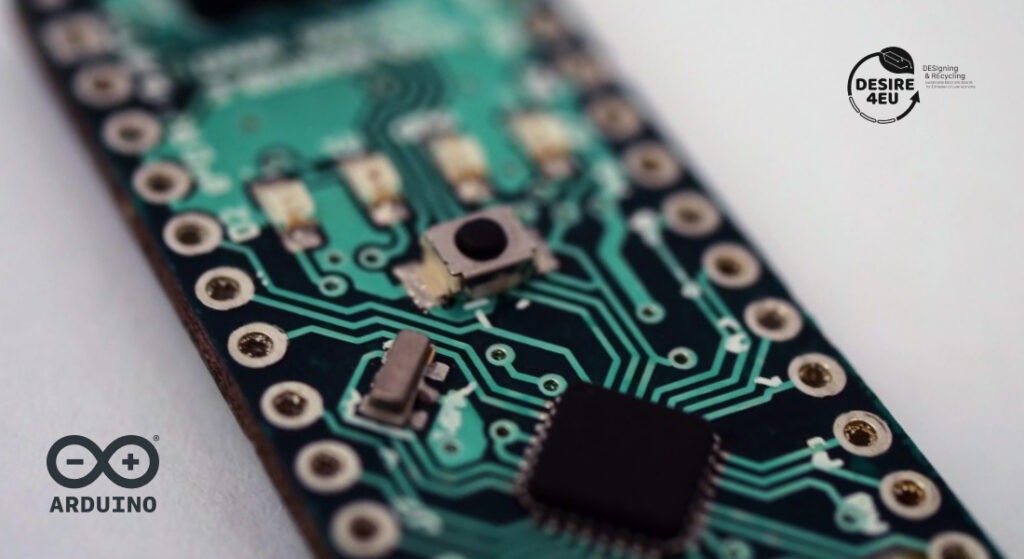

One of the crucial thrilling steps in that route is our work on bio-based printed circuit boards (PCBs) – introduced by co-founder David Cuartielles throughout this yr’s Arduino Days. It’s an effort to basically rethink how electronics are made, used, and ultimately disposed of.

Introducing the Desire4EU venture

Our bio-based PCB initiative is a part of Desire4EU, a European venture funded by the European Innovation Council (GA N°101161251). Operating from 2024 to 2028, it brings collectively researchers and engineers from Sweden, Italy, Hungary, Belgium, and France. The objective: to design and check bio-based multilayer PCBs that scale back environmental impression, with out compromising on performance or efficiency.

Companions embrace the Budapest College of Expertise and Economics, CROMA on the Université Grenoble Alpes, the Catholic College of Leuven, and others. Arduino is proud to contribute each open {hardware} designs and real-world testing because of the Arduino neighborhood – hey, that’s you!

The primary working prototypes have already been manufactured utilizing a brand new flame-retardant composite made out of PLA-flax, as a substitute of conventional fiberglass and epoxy. And sure, it really works: the crew has already efficiently replicated Arduino Nano and UNO boards utilizing this new bio-based substrate.

A holistic strategy for sustainability

As Pascal Xavier (researcher at CROMA and professor on the Expertise College Institute in Grenoble) identified throughout Arduino Days, making boards bio-compatible first and biodegradable second is a step ahead in managing rising volumes of e-waste that gather on our planet. However advantages don’t cease there, as a result of to benefit from the brand new supplies, researchers needed to decrease soldering temperatures – resulting in decrease vitality consumption throughout manufacturing. This helps scale back not simply end-of-life waste, however the whole environmental footprint of electronics manufacturing.

In line with a paper the crew printed on Nanotechnology within the early phases of the venture, meeting with the brand new materials continues to be appropriate with commonplace floor mounted expertise (SMT), that means no costly new infrastructure is required. Additionally, the brand new boards use optimized layouts to enhance yield and reliability – even with double-sided designs and through-hole vias.

Trying past the board: full lifecycle impression issues

All of those features (and extra) are being thought-about to validate the environmental advantages of the venture in a holistic perspective. A Life Cycle Evaluation (LCA) is being carried out by the crew on the Catholic College of Leuven, leveraging all the required knowledge to quantify how a lot waste and CO? might be saved, the vitality financial savings throughout manufacturing, and the potential for bio-leaching. The latter gives a option to get well high-purity copper from used PCBs utilizing bacterial processes, as a substitute of energy-intensive chemical remedies.

In the intervening time, we estimate that 90% of the standard FR4 substrate (the composite materials made with woven fiberglass material and an epoxy resin binder historically used) might be changed with sustainable supplies – with out altering the conduct of the board throughout use at excessive environmental circumstances?.

Designing with the planet in thoughts (and barely altering a factor)

What modifications when design meets bio-compatibility? Surprisingly little in keeping with Attila Géczy (head researcher in bio-based electronics on the Budapest College of Expertise and Economics), who took half within the Arduino Days announcement to supply fascinating technical particulars. Most present Arduino board designs might be tailored with minimal modifications. A couple of structure tweaks – like teardrop pads and improved through constructions – assist guarantee dependable manufacturing, however the general workflow stays acquainted to any embedded designer. That’s essential if we wish these applied sciences to be adopted broadly, not simply experimentally.

Be a part of the answer!

As a part of the Desire4EU venture, we’ll be making a gift of 1,000 beta boards beginning in April 2026 – constructed on this new sustainable substrate and that includes an open-source design with LoRa® wi-fi connectivity.

We’re searching for testers, educators, and innovators to assist us consider efficiency in real-world functions. If you happen to’re interested by becoming a member of this system, keep tuned: we’ll share extra within the coming months.

Within the meantime, you may discover the full scientific paper on the venture, printed in Nanotechnology within the early phases of analysis, in addition to comply with the venture’s improvement on the official Desire4EU web site.

Collectively, let’s construct electronics which are smarter, extra accountable – and constructed to final in each sense.