AI can discover hidden cracks inside machines and buildings in actual time, serving to stop accidents and preserve industries secure.

Reliability and security are essential in industries like semiconductors, power, automotive, and metal, the place tiny cracks or defects can vastly influence efficiency. As a result of these flaws are hidden inside supplies, non-destructive testing (NDT) has been used to test their situation with out inflicting harm. Nonetheless, precisely detecting and mapping inner defects stays very difficult. Indicators from bodily sensors, like ultrasonic or electromagnetic waves, are sometimes distorted by elements reminiscent of geometry, materials properties, and real-world situations. This makes it inherently troublesome to pinpoint the placement and measurement of defects precisely.

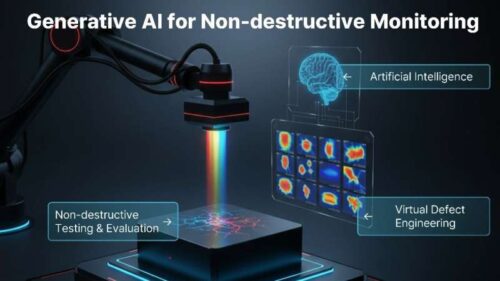

However what if synthetic intelligence (AI) may “see” what people can’t? Impressed by this concept, a analysis crew in South Korea from Chung-Ang College have developed DiffectNet. This diffusion-enabled conditional goal technology community can create high-fidelity, defect-aware ultrasonic photographs. Their findings have been revealed on 1 November 2025 in Mechanical Techniques and Sign Processing.

By overcoming the restrictions of conventional strategies, AI can elevate the integrity and security of commercial methods to a brand new stage. The expertise represents a basic breakthrough, creating generative AI able to reconstructing hidden cracks inside constructions in actual time, surpassing the bodily limits of typical approaches.

Correct AI detection and reconstruction of inner defects can allow accident prevention, even in environments which are troublesome or harmful for people to entry. In energy vegetation, for instance, even a tiny crack can set off catastrophic accidents. AI-based real-time monitoring permits early warnings of potential anomalies, lowering threat.

In semiconductor and superior manufacturing amenities, AI can nearly reconstruct inner defects with out halting gear, bettering high quality management whereas sustaining productiveness. The expertise will also be utilized to real-time monitoring of infrastructure, reminiscent of buildings and bridges, supporting smarter and extra resilient city security administration.

These purposes illustrate how AI is enabling engineering capabilities as soon as thought not possible. By performing because the “eyes” of constructions, AI opens new prospects for real-time defect reconstruction and prediction in reliability-critical industries, together with aerospace, energy technology, semiconductor manufacturing, and civil infrastructure.