Researchers on the FAMU-FSU Faculty of Engineering are growing instruments that use synthetic intelligence to establish defects in powder-based steel 3D printing. The $2.2 million mission, funded by the Air Drive Workplace of Scientific Analysis, focuses on binder jetting know-how. This 3D printing technique makes use of liquid binder to hitch powdered supplies and is valued for creating advanced steel elements with larger productiveness than different steel printing processes.

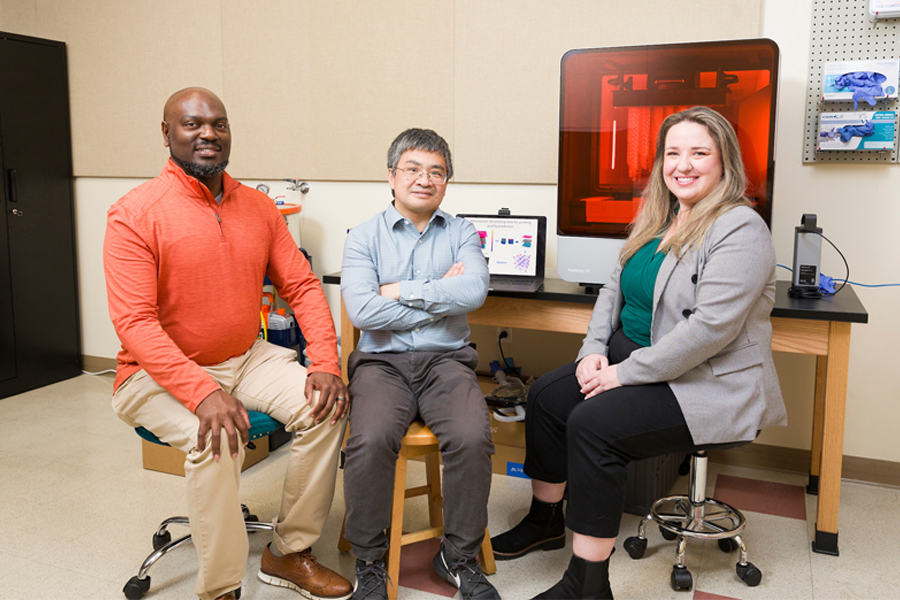

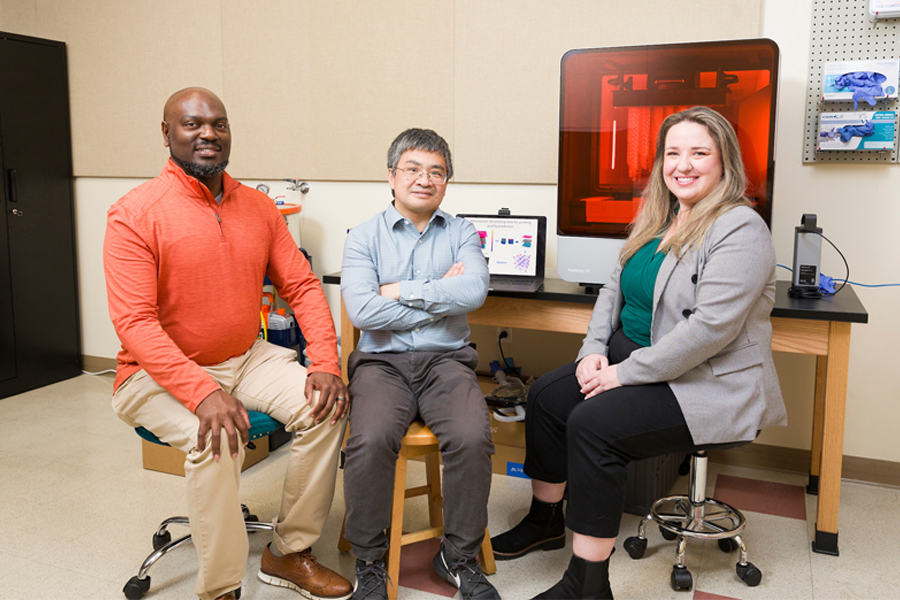

The analysis group, led by Affiliate Professor Hui Wang, is making use of combinatorial generalization (CG) to enhance defect prediction fashions. “Combinatorial generalization represents a computational reasoning functionality that helps next-generation AI by mimicking human recognition habits that generates new information from knowledge,” Wang stated. The mission goals to deal with porosity points that generally happen in powder-based fabrication.

Powder-based 3D printing serves quite a few industries together with aerospace, automotive, healthcare, and navy purposes. The researchers are collaborating with Pennsylvania State College and HP Inc. to advance this know-how. Penn State is contributing simulations and XCT knowledge modeling, whereas HP is offering entry to knowledge from their 3D Printing and Digital Manufacturing Middle of Excellence.

The mission provides important instructional alternatives for college students. FAMU-FSU doctoral and undergraduate college students have participated in HP internships, gaining sensible expertise within the discipline. The funding additionally helps researchers purchase important experimental supplies and small-scale testing tools for the faculty.

“This know-how might democratize manufacturing, making it simpler for inexperienced producers to advance from lab testing to large-scale manufacturing,” Wang defined. Past manufacturing purposes, the analysis has potential advantages for system upkeep and cybersecurity. The interdisciplinary method combines experience in industrial and manufacturing engineering with new AI capabilities.

Supply: information.fsu.edu