Fabric8Labs, a San Diego-based producer specializing in Electrochemical Additive Manufacturing (ECAM), has been chosen by AEWIN Applied sciences to produce thermal administration elements for its subsequent technology of Edge AI techniques. AEWIN, a supplier of high-performance community platforms and a member of the Qisda Enterprise Group, will combine ECAM-produced copper elements into its upcoming cooling infrastructure.

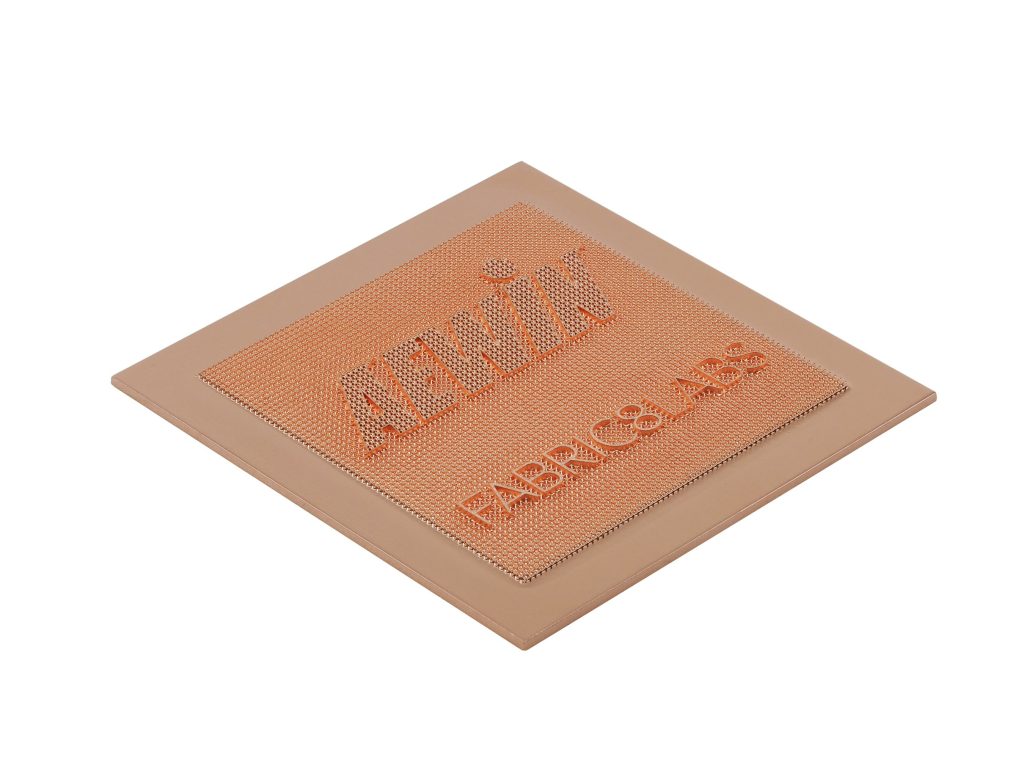

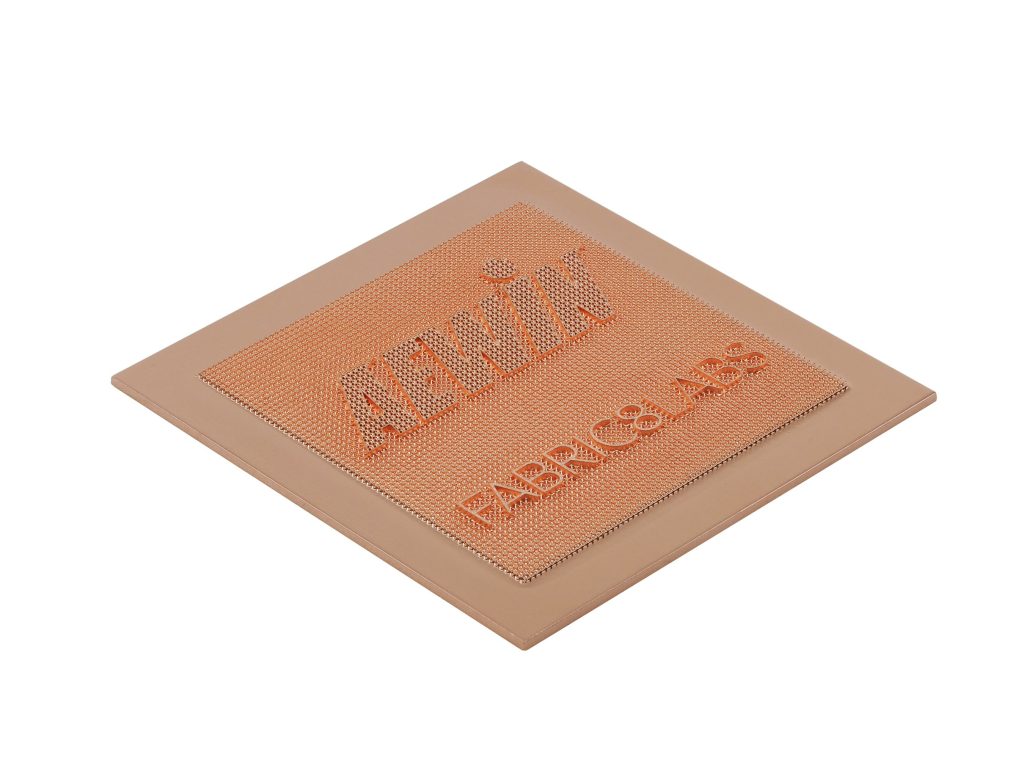

The partnership addresses rising thermal challenges in high-density computing environments. Fabric8Labs’ ECAM course of permits the additive manufacturing of pure copper constructions with excessive geometric decision. AEWIN is deploying ECAM-based 3D micro-mesh boiler plates that enhance warmth exchanger floor space by over 900% and supply thermal enhancements larger than 1.3 °C per 100W in comparison with main standard alternate options.

“Our collaboration with AEWIN represents a big step ahead towards the way forward for thermal administration. We’re thrilled to help AEWIN by enabling them to realize their sustainability targets and meet the rising energy calls for of superior AI accelerators,” mentioned Ian Winfield, Vice President of Product & Functions at Fabric8Labs.

AEWIN’s system-level designs are optimized for each PFAS and PFAS-free coolants, supporting varied two-phase immersion cooling methodologies. In accordance with Dr. Liu, Director of the Superior Technical Growth Division at AEWIN Applied sciences, “The exponential progress of knowledge and Edge AI complexity requires essentially the most superior on-premises computing. Via our superior system-level design, we’re in a position to leverage Fabric8Labs’ ECAM know-how to optimize options for prime effectivity, energy utilization effectiveness, and diminished whole value of possession.”

The ECAM manufacturing platform permits the manufacturing of 3D cooling constructions with out requiring powder beds or laser-based processes. Fabric8Labs’ strategy permits for the fabrication of advanced copper geometries appropriate for thermal administration functions, together with capillary community designs that improve coolant circulate on the boiling interface. AEWIN experiences that the usage of these ECAM-enabled boiler plates helps reaching Energy Utilization Effectiveness (PUE) beneath 1.02.

Based in 2015, Fabric8Labs develops ECAM techniques for electronics, medical units, communications gear, and semiconductor manufacturing. Its know-how is designed to help dense thermal architectures in information facilities and Edge AI infrastructure. The additive course of is able to producing detailed constructions with diminished materials waste in comparison with standard subtractive or powder-based strategies.

AEWIN will exhibit its superior immersion cooling platform using ECAM-enabled thermal elements at Computex 2025, Sales space No. M0120.

3D Printed Thermal Parts Develop Throughout Sectors

Donkervoort Automobielen, a Dutch supercar producer, not too long ago partnered with Australia-based Conflux Know-how to combine 3D printed water-charge air coolers (WCAC) into its P24 RS mannequin. Utilizing aluminum alloys and tailor-made fin geometries, the Conflux-designed WCAC items scale back weight from 16 kg to simply 1.4 kg per cooler. By relocating the system into the engine bay and shortening the inlet tract, the brand new thermal structure enhances throttle response and packaging effectivity. The additively manufactured design, impressed by System 1 cooling know-how, was tailored for a road-legal automobile.

In one other latest instance, Alloy Enterprises developed a high-efficiency chilly plate for NVIDIA’s H100 PCIe card, addressing energy density challenges in superior computing. The element was fabricated from 6061 aluminum utilizing the corporate’s proprietary Stack Forging course of. It options 180-micron microcapillaries, gyroid infill, and monolithic inlet/outlet channels—all optimized utilizing nTop’s generative design software program. With a ultimate weight beneath 550 grams, the liquid chilly plate delivers focused cooling by way of simulation-derived inside constructions.

Prepared to find who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to remain up to date with the newest information and insights.

Take the 3DPI Reader Survey — form the way forward for AM reporting in beneath 5 minutes.

Featured picture reveals ECAM permits high-resolution, personalized designs. Picture by way of Fabric8Labs.