Excessive-power induction cookers may cause interference. This reference design reveals how one can scale back EMI and make the cooker work and warmth correctly.

Half-bridge induction cookers are extensively used as a result of they’ll ship each high- and low-power heating effectively. Nevertheless, at excessive energy, the quick switching of IGBTs generates narrow-band electromagnetic interference (EMI), which might disrupt close by digital gadgets. As households more and more depend on a number of digital programs, electromagnetic compatibility (EMC) has turn out to be a important concern for engineers designing induction cookers. Shoppers count on home equipment to function reliably with out affecting different gadgets, and engineers face the problem of balancing excessive energy output with low EMI.

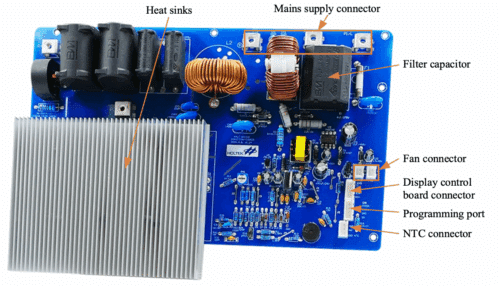

Holtek’s EMC-enhanced half-bridge induction cooker reference design addresses these challenges, offering a framework that design engineers can leverage to enhance EMI efficiency and reliability. The design employs a dual-board construction consisting of an influence heating board and a show management board. The show board, managed by the MCU, handles contact enter, LED driving, and noise immunity, whereas speaking with the facility heating board by way of the I2C interface. This separation of management and energy permits engineers to isolate noise-sensitive features and enhance system stability.

The facility heating board is constructed across the MCU, a extremely built-in controller tailor-made for half-bridge induction cookers. This MCU options 12-bit complementary PWM outputs with dead-time management, permitting engineers to adapt the outputs to a variety of IGBTs. It consists of 9 over-voltage safety (OVP) circuits, which offer AC voltage surge safety, over-current safety for the IGBT and resonance present, LC resonant present and voltage part detection, and AC voltage zero-cross detection. An built-in OPA circuit amplifies and measures AC present, enabling correct energy calculation. The MCU additionally helps frequency jittering, a method that modulates the IGBT switching frequency to cut back peak interference and again voltage, additional reducing EMI. Engineers can use these options to guard the system, optimize efficiency, and simplify adaptation to completely different {hardware} configurations.

The reference design incorporates a devoted EMC circuit that works with frequency jittering to disperse interference power throughout a wider spectrum. This features equally to a variety spectrum method, decreasing the amplitude of peak EMI indicators and enhancing CE carried out interference margins. For engineers, which means that compliance testing will be achieved extra simply, and designs are extra strong towards electromagnetic noise in real-world environments.

The half-bridge structure itself gives excessive reliability and environment friendly energy conversion. Twin IGBT inverter modules deal with alternating present constructive and destructive half-cycles, delivering excessive present conversion effectivity and diminished losses. In operation, a rectifier converts 50 Hz AC to DC, which passes by way of an LC resonance circuit and the IGBT switching circuit. That is transformed right into a 20–50 kHz high-frequency AC present, producing a magnetic area within the induction coil. When cookware is positioned on the cooktop, the magnetic area induces eddy currents within the metallic base, producing warmth effectively.

Holtek has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) structure, and extra. The corporate’s web site has extra information in regards to the reference design. To learn extra about this reference design, click on right here.