If you stroll into Cascade Espresso’s facility north of Seattle, you instantly sense two issues: the unmistakable scent of freshly roasted beans, and a crew that’s genuinely pleased with the work they do.

That second half didn’t occur accidentally.

It’s the results of a daring determination Cascade made about 4 years in the past: exchange one of the crucial painful, turnover-heavy, inconsistent handbook jobs within the manufacturing unit with collaborative robots. What began as a single low-risk experiment snowballed into a scientific, company-wide transformation touching productiveness, folks, and tradition.

I lately sat down with Cascade’s COO, Ron Kane, to retrace that journey. Ron’s spent greater than 30 years in meals and beverage—Nestlé Waters, Monster Power, craft beer—so he’s seen each taste of automation challenge, from the profitable to the painful. His perspective is extraordinarily grounded in what producers reside day-after-day.

Right here’s Cascade’s story, and the teachings any meals and bev manufacturing unit can apply.

When development meets actuality

In 2020, Cascade shifted from serving one main buyer (80% of their quantity) to supporting a broad portfolio of manufacturers, particularly progressive ecommerce gamers. It unlocked development, however elevated complexity in a single day.

The issue? Practically every part downstream was nonetheless handbook.

- Operators had been hand-stacking dozens of pallet configurations

- Turnover on the palletizing function was over 60%

- New hires had been educated nearly weekly on intricate customer-specific patterns

- High quality errors—like misaligned labels on shipments—had been eroding buyer satisfaction

And culturally, no person needed the palletizing job. It was bodily demanding, low selection, and traumatic.

“It didn’t present worth for us as a manufacturing unit. It wanted to be finished, but it surely actually ought to have been automated if there was a solution to do it.”

– Ron Kane, COO

The problem was the identical one many mid-sized producers face: conventional palletizers had been too large, too costly, and too advanced for his or her footprint.

The primary leap: A sensible, low-risk check

When Cascade bought a brand new high-volume Okay-Cup line, Ron noticed a possibility: in the event that they had been upgrading processing and packaging, why cease there?

He evaluated the complete image: labor, ergonomics, turnover, uptime, and buyer necessities and proposed trialing a cobot palletizer. The preliminary ROI estimate was just below two years, already strong.

What occurred subsequent shocked everybody.

Their native associate, Olympus Controls, rolled the system into place. Inside hours, it was bolted down. By the following afternoon, it was palletizing reside manufacturing.

No cages. No advanced programming. No weeks of commissioning.

Operators discovered the interface in minutes. The protection conduct instantly earned their belief. And the cultural shift occurred quicker than anticipated: the crew named the robotic, embellished it for holidays, and handled it as a further coworker.

“We put in the robotic, didn’t lose any headcount, and it grew to become a part of the persona of the manufacturing unit.”

9 months to payback, not two years

When the primary audit was full, the numbers got here in…

Precise ROI: 9 months.

Why the dramatic distinction?

- Increased uptime than anticipated

- Constant throughput, even throughout variable quantity

- No unplanned labor protection for downtime

- Fewer high quality points

- Rising quantity on the road

In three years, Ron can depend on one hand the variety of days any palletizer has been down. And people uncommon points? Normally from packaging anomalies, not the robotic.

That reliability grew to become the explanation Cascade may scale confidently.

Scaling systematically: From one to 6 (and counting!)

-2.jpg?width=685&height=385&name=Robotiq%20Background%20(Cascade%20Coffee)-2.jpg)

As soon as the primary cell proved itself, Cascade replicated the method throughout each retail bag line within the manufacturing unit.

As a result of their mechanics and engineers already understood the interface, subsequent installations grew to become almost plug-and-play:

- Nonetheless delivered in crates

- Nonetheless bolted down in hours

- Nonetheless operational the following day

- Nonetheless simple to troubleshoot independently

One line went from crate arrival to operating manufacturing by the top of the primary shift.

And their crew began collaborating with our engineers on efficiency upgrades—like early adoption of dual-case choosing to spice up throughput with out rising pace.

The outcome was: a standardized, repeatable palletizing technique throughout your complete web site.

Actual enterprise affect: Hundreds of thousands saved, folks lifted up

Cascade Espresso invested just below seven figures throughout all methods.

They’ve already recouped a number of hundreds of thousands in labor effectivity.

However the half Ron speaks about with essentially the most pleasure isn’t the monetary return; it’s the folks.

The staff who as soon as rotated by way of the toughest job within the plant are nonetheless there. Many have moved as much as higher-skill roles.

“They’re constructing careers, not simply doing jobs. They’re incomes extra for his or her households. They’re extra assured working larger gear as a result of they discovered on the cobot first.”

Automation didn’t scale back headcount. It truly created new alternative.

And it was an incredible match culturally as effectively. The robots have names, vacation outfits, and recurring appearances on Cascade’s LinkedIn web page. They’ve change into a part of the crew!

Classes for producers contemplating automation

Listed here are the takeaways Ron would give anybody simply beginning their automation journey:

1. Your actual ROI will possible be higher than your spreadsheet.

Producers usually underestimate the impact of constant throughput and overestimate downtime threat.

2. Begin the place the ache is highest and the labor is hardest to retain.

Palletizing jobs burn folks out rapidly. Fixing that ache advantages the entire operation.

3. Tradition issues as a lot as expertise.

Talk clearly that automation removes undesirable duties—not folks.

4. Standardize early.

As soon as one cell is operating effectively, you may replicate it effectively throughout comparable traces.

5. A powerful native associate makes all of the distinction.

Olympus Controls helped Cascade deploy quick and adapt rapidly, at the same time as wants modified.

What this story actually reveals

Automation doesn’t should be costly, dangerous, or disruptive. When finished systematically (and with folks in thoughts) it turns into a catalyst for higher work, higher throughput, and higher enterprise.

Cascade Espresso went from handbook palletizing with excessive turnover to a completely automated, extremely engaged crew that’s assured, rising, and able to tackle extra.

Their journey is strictly why we consider in Lean Robotics: begin small, scale quick, and construct functionality by way of each part: design, combine, function.

Ron stated it greatest:

“You gave us the primary steps. We wouldn’t be pursuing automation this aggressively with out that early success.”

And that’s the sort of affect we would like each producer to expertise.

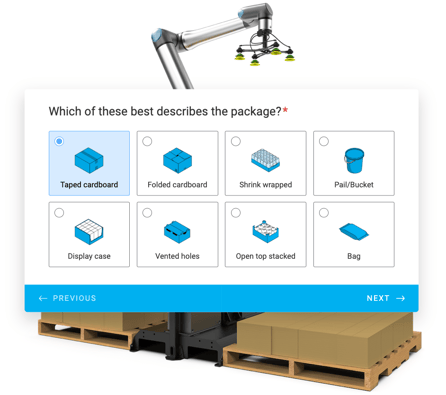

If you wish to see whether or not palletizing automation is smart to your facility, begin with the Palletizing Match Device — a fast, interactive solution to see if Lean Palletizing is the precise match to your line.

Need extra tales from actual factories like yours?

Observe Robotiq on LinkedIn and be part of over 75,000 producers seeing how automation retains folks secure, and manufacturing operating sturdy.

-2.jpg?w=696&resize=696,0&ssl=1)