A brand new rhodium-based materials combines distinctive power, elasticity, and conductivity to boost probe pin efficiency and prolong the lifetime of semiconductor testing techniques.

As semiconductor units shrink and combine extra densely packed circuits, testing precision and reliability have turn out to be essential on the wafer degree. To handle the mechanical limits of present probe pin supplies, a brand new rhodium alloy—TK-SR—has been developed by TANAKA PRECIOUS METAL TECHNOLOGIES , to ship an unprecedented stability of power, elasticity, hardness, and conductivity.

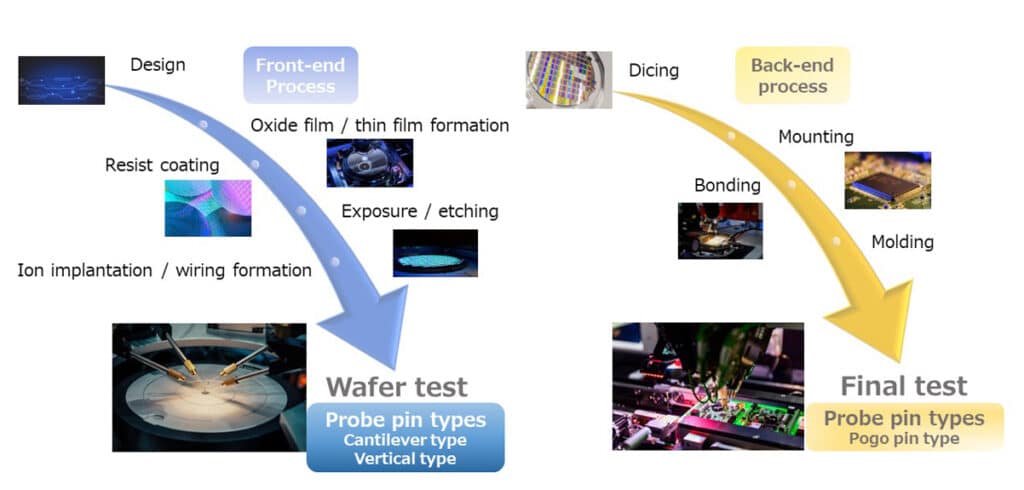

Probe pins, utilized in probe playing cards throughout front-end semiconductor testing, are subjected to repetitive micro-scale mechanical hundreds—typically tens of millions of cycles—whereas carrying take a look at currents to wafer contacts. Even minor deformation or fatigue in a pin can result in failure, leading to expensive downtime and substitute of probe playing cards. The TK-SR alloy instantly targets this situation by considerably rising the elastic restrict and sturdiness of rhodium wire, enabling constant efficiency underneath excessive cyclic stress.

The important thing options are:

- Excessive Energy & Elasticity

- Enhanced Hardness

- Extremely-Wonderful Wire Functionality

- Subsequent-Technology Materials Processing

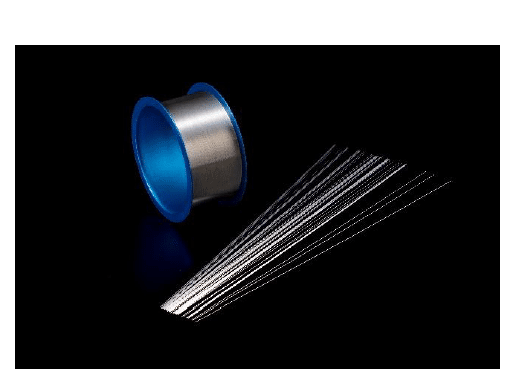

Developed utilizing superior materials processing know-how, this materials could be drawn into ultra-fine wires as slim as 18 micrometers. This degree of precision helps testing of narrow-pitch, high-density semiconductor packages used throughout smartphones, information facilities, and automotive electronics. By sustaining each mechanical stability and electrical conductivity, the fabric ensures decrease contact resistance and improved reliability in repeated probing operations.

In line with the corporate, its enhanced mechanical properties scale back deformation and breakage threat, serving to prolong probe card lifespan and decrease whole price of possession. In comparison with standard rhodium wire, it displays increased yield power and stress tolerance—key components for sustaining contact accuracy and lowering pin substitute frequency.

By 2030, the corporate goals to double the cargo quantity of TK-SR in comparison with its present rhodium-based probe merchandise, underscoring demand development in semiconductor take a look at infrastructure. Additional info on the probe pin portfolio, together with wire, plate, and plating options for semiconductor testing, is on the market by clicking right here.