Introduction

Silicon has been the first driver of the computing development for many years, however Moore’s Legislation is now reaching its limits. As the necessity for chips to be sooner and extra energy-efficient grows, the stress on provide chains are like by no means earlier than attributable to shortages and geopolitical tensions.

That is the place AI and quantum computing come into play. It isn’t science fiction; they’re serving to uncover new semiconductor supplies and optimizing manufacturing scheduling in wafer fabs. This ends in shorter lead instances, decreased dangers, and a extra resilient provide chain.

For engineers and procurement groups, the message is easy: maintaining within the chip world

will quickly require leveraging each quantum computing and AI collectively.

Quantum Computing and AI Integration in Semiconductor Innovation

Quantum computing works with qubits, which, not like classical bits, can exist in superposition, representing each 0 and 1 concurrently. This allows quantum processors to deal with advanced simulations that classical computer systems wrestle with, equivalent to modelling atomic-level behaviour in new semiconductor supplies.

AI enhances this functionality. By making use of predictive analytics to quantum simulations, machine studying fashions establish promising materials candidates, predict their efficiency, and advocate changes. This transforms what was as soon as a sluggish trial-and-error course of into actionable insights, saving years of laboratory work.

Take Google’s Willow processor for example. It’s the follow-up to Sycamore, and whereas not constructed solely for supplies analysis, it demonstrates how quantum methods can scale and scale back errors. When mixed with machine studying, it offers an unprecedented view of fabric properties important for chip innovation.

As Anima Anandkumar factors out: “AI helps us flip the uncooked complexity of quantum simulations into insights engineers can truly use.”- Anima Anandkumar, Professor, Caltech & Senior Director of AI Analysis, Nvidia.

Collectively, AI and quantum computing are laying the muse for a essentially new strategy to chip design.

AI-Pushed Materials Science: Operational and Market Impression

In terms of discovering new semiconductors, atomic-level precision is essential. AI- powered quantum fashions can simulate electron behaviour in supplies equivalent to graphene, gallium nitride, or perovskites. This allows researchers to guage conductivity, power effectivity, and sturdiness earlier than performing laboratory assessments, vastly accelerating materials qualification.

The sensible impression is important. Materials validation historically took years, however early research point out that timelines might be shortened by 30 to 50 %. This permits wafer fabs to function extra effectively, align manufacturing with new improvements, and decrease idle time.

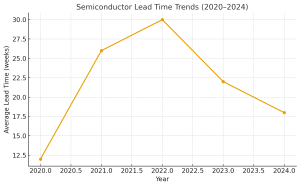

Market pressures additional complicate the scenario. Throughout the 2021 scarcity, lead instances elevated from roughly 12 weeks to over a yr. With AI, corporations can anticipate provide chain disruptions and proactively regulate sourcing methods. Quantum simulations additionally increase the vary of usable supplies, decreasing reliance on a single provider or high-risk area.

Determine 1. Semiconductor lead instances spiked from 12 weeks in 2020 to over 30 weeks in 2022 earlier than easing. AI-quantum integration can assist stabilize these fluctuations by enabling predictive analytics and diversified sourcing.

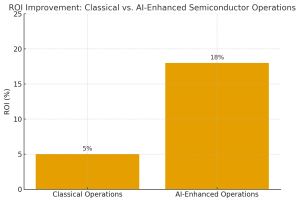

The return on funding is outstanding. In response to Deloitte, corporations that combine AI into R&D and provide chain operations are reaching double-digit effectivity features, primarily attributable to improved yield forecasting and decreased downtime. Google’s quantum analysis group has demonstrated that AI-driven simulations can slender the listing of promising supplies from hundreds to only a few inside weeks, a course of that might usually take years utilizing classical computing. This dramatic compression of the R&D cycle essentially modifications aggressive dynamics.

Strategic Insights for Procurement and Provide Chain Leaders

For procurement and provide chain leaders, that is greater than only a technical improve; it represents a real strategic benefit. AI-powered quantum instruments assist optimize lead instances, enabling extra exact provider contracts and decreasing the necessity for extra buffer inventory. Predictive analytics additionally enable groups to establish potential dangers earlier than they have an effect on wafer fabs or delay buyer deliveries.

Provide chain resilience can be enhanced. When AI-guided quantum simulations affirm various semiconductors that may be sourced from totally different areas, procurement groups scale back publicity to geopolitical dangers or pure disasters. This strategy aligns with nationwide initiatives such because the U.S. CHIPS and Science Act and the EU Chips Act, each of which promote stronger native manufacturing and extra resilient sourcing methods. Quantum-AI modelling offers the technical confidence required to qualify these various provide streams.

“The upward trajectory for the business within the short-term is obvious, however the corporations that may handle their provide chains and entice and retain expertise would be the ones well-positioned to maintain and profit from the AI increase.”- Mark Gibson, World Know-how Chief, KPMG

Determine 2. Corporations adopting AI-enhanced semiconductor operations obtain significantly greater ROI, with consulting research reporting double-digit effectivity features in comparison with classical operations.

On the finish of the day, corporations that efficiently combine these applied sciences don’t simply deliver merchandise to market sooner; additionally they acquire a real aggressive edge in at the moment’s unpredictable world markets. Within the semiconductor business, a delay of some weeks may end up in billions in misplaced income, so agility is crucial for survival.

Future Outlook: Scaling Quantum AI Impression on Semiconductor Manufacturing

Wanting forward, the subsequent main growth seems to be full-stack quantum-AI design. Think about quantum processors working full-chip simulations whereas AI optimizes them for velocity, effectivity, and manufacturability. Though we aren’t there but, incremental advances in photonic circuits and spintronic parts are already producing tangible outcomes.

For manufacturing groups, the problem will likely be sustaining flexibility in provide chains. As new supplies transfer from simulation to pilot manufacturing, procurement and fab groups should scale in coordination. As we speak’s quantum processors will not be excellent, as they nonetheless face limitations in qubit counts, error charges, and scalability, but when progress continues, sensible industrial purposes may emerge inside the subsequent ten years. Firms that start planning now, by growing roadmaps and forming strategic partnerships, will acquire a major benefit.

Conclusion

Proper now, the semiconductor business is at a important turning level. Combining AI’s predictive capabilities with quantum computing’s atomic-level insights can speed up discovery, shorten lead instances, and make provide chains considerably extra resilient. For engineers and procurement leaders, the message is obvious: adopting AI-quantum integration is not only about expertise; it’s about remaining aggressive. The subsequent main development in silicon is not going to happen by likelihood. Will probably be rigorously designed, optimized, and engineered utilizing AI and quantum computing collectively.