India’s electronics development story is not going to be written by meeting alone. Embedding Design for Manufacturing into each stage of product creation is the step that may rework ambition into international competitiveness—and make India a real chief in electronics.

India’s push towards self-reliance in electronics is being examined throughout high-stakes sectors—defence, railways, vitality, aerospace, and industrial techniques—all of which demand {hardware} that’s rugged, dependable, and scalable.

The outdated mannequin of import dependence and meeting is giving option to one thing much more bold: digital design for manufacturing (DFM).

Not a peripheral observe, DFM has change into the inspiration for producing {hardware} that meets international requirements whereas withstanding real-world working challenges, making it indispensable to India’s rise as a severe electronics contender.

The Indian Electronics Ecosystem: Context and Imperatives

Defence, aerospace, railways, oil and fuel, and renewable vitality are all shifting quickly in the direction of digitisation, making a surge in demand for {hardware} that may stand up to harsh situations whereas delivering constant efficiency. Assembly this demand requires greater than incremental upgrades—it requires a design philosophy that anticipates scale, reliability, and manufacturability from the outset.

For instance, Indian Railways is endeavor the large-scale deployment of related techniques to boost each operational effectivity and security throughout its huge community. On the similar time, Industrial IoT is remodeling key sectors corresponding to oil and fuel, manufacturing, and vitality, necessitating using strong gateways and clever edge gadgets to make sure dependable information processing and connectivity. In the meantime, the buyer electronics market continues its speedy growth, fuelling demand for revolutionary, high-quality merchandise that meet evolving person expectations.

This evolution is underpinned by a nationwide push for ‘Made in India’ electronics, not simply as an meeting hub, however as a design and manufacturing powerhouse. Geopolitical shifts and provide chain disruptions have opened alternatives for India to emerge as an alternative choice to China. Nevertheless, this additionally exposes vulnerabilities, particularly in part sourcing, R&D infrastructure, and manufacturing maturity.

DFM: Rules and Technical Foundations

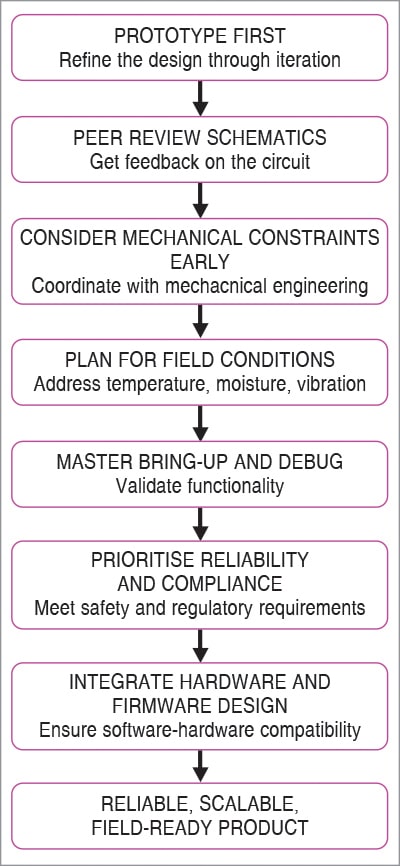

DFM is an engineering method targeted on creating digital merchandise which can be optimised for manufacturing, meeting, testing, and long-term efficiency. By incorporating DFM rules early within the design course of, engineers be sure that merchandise are simple to fabricate at scale, preserve constant high quality, stay cost-effective, adjust to related {industry} requirements, and carry out reliably in real-world situations.

DFM is central to making sure that the product strikes seamlessly from idea to manufacturing. A design mustn’t solely be purposeful at prototype stage but additionally strong sufficient to be fabricated, assembled, and examined repeatedly and reliably.

The advantages of DFM are important throughout the product lifecycle. By minimising manufacturing defects and the necessity for rework, DFM helps decrease general manufacturing prices. It additionally facilitates improved automation and scalability, enabling extra environment friendly manufacturing processes. Moreover, DFM contributes to enhanced product high quality and better buyer satisfaction, whereas accelerating time-to-market for brand new merchandise.

India-specific DFM Challenges

India stays closely depending on imported parts—particularly semiconductors, sensors, and superior shows. This exposes the availability chain to price fluctuations and delays.

Manufacturing infrastructure limitations embody:

PCB Fabrication

Superior PCBs (for instance, having >6 layers, positive traces) are difficult to supply domestically, particularly for low-volume runs.

Enclosure Fabrication

High quality, low-volume enclosure manufacturing is proscribed, affecting startups and SMEs.

Testing Labs

Entry to licensed, third-party testing amenities is scarce, inflicting delays in validation and compliance.

Abilities and ecosystem gaps embody:

Design Experience

Many engineers lack expertise in DFM, compliance, and system reliability.

Academia-industry Disconnect

Curricula usually lag behind {industry} wants, particularly in utilized design and compliance engineering.

Prototyping Ecosystem

The ecosystem for speedy prototyping and validation remains to be maturing, with lengthy lead occasions and regulatory hurdles.

India has confirmed itself a worldwide software program powerhouse. Nevertheless, many software program engineers coming into embedded domains are usually not educated in systematic {hardware}–software program co-design. Startups and SMEs, whereas nimble, usually lack the luxurious of time or structured mentorship.

In consequence, firmware engineers are sometimes pushed into initiatives with a “code-first” mindset—writing code with out correct structure, documentation, or planning. This method can rapidly result in unscalable, untestable, and difficult-to-debug codebases.

Go-to-market Pressures: Hidden Dangers for Startups and SMEs

EFY++ CONTENT: ACCESS TO THIS CONTENT IS FREE! BUT YOU NEED TO BE A REGISTERED USER.