Lithium–sulfur chemistry permits larger power density utilizing low-cost sulfur as a substitute of metals present in lithium-ion batteries.

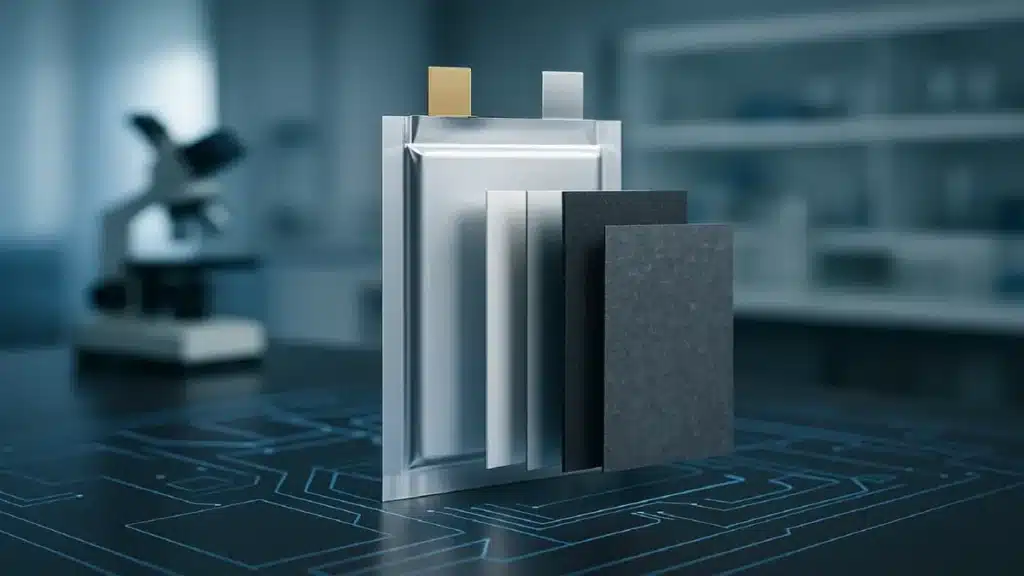

The analysis workforce has constructed a brand new solid-state lithium–sulfur (Li–S) battery that shops as much as 600 watt-hours of power per kilogram. The know-how goals to make batteries lighter, safer and extra environment friendly to be used in electrical automobiles, plane, drones and moveable energy programs

Lithium–sulfur batteries use sulfur as a substitute of the costly metals present in Li-ion cells. Sulfur is reasonable and simply accessible, and it may possibly retailer extra power by weight. However earlier variations of Li–S batteries confronted issues as a result of the liquid electrolytes inside them fashioned undesirable compounds known as polysulfides. These brought on power loss and decreased battery life.

To repair this, the German analysis workforce changed the liquid a part of the battery with strong supplies. This makes the battery extra secure and reduces chemical injury over time. The design makes use of a sulfur–carbon cathode, a skinny lithium-metal anode, and a hybrid strong electrolyte. The workforce goals to achieve 550 Wh/kg at a price under $86 per kilowatt-hour, making it appropriate for large-scale manufacturing.

The undertaking additionally makes use of the workforce’s DRYtraec coating methodology, which removes the necessity for chemical solvents throughout manufacturing. This course of saves as much as 30 per cent of manufacturing power and lowers carbon emissions. It additionally matches into present lithium-ion manufacturing strains, making it simpler for producers to undertake.

All testing and prototype work are happening at Fraunhofer’s Superior Battery Know-how Centre in Germany. The workforce plans to ship working prototypes throughout the subsequent few years for industries that want excessive power and low weight, reminiscent of electrical aviation and unmanned aerial programs.