A typical lab software could also be distorting what we expect we find out about lithium batteries. A frozen twist now reveals a more true image and it adjustments the story.

When one thing is measured it may be modified by the act of measurement. A typical case is checking tire strain. When the gauge is hooked up, air escapes and the strain shifts. The identical problem exists in supplies analysis. To observe a chemical response inside a cloth, scientists fireplace X-rays at it, however the beam itself can set off reactions and alter the fabric. This has restricted progress in areas akin to rechargeable batteries.

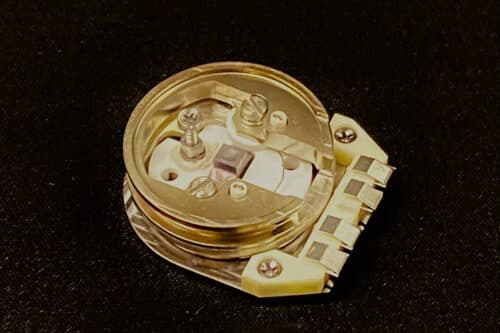

Lithium metallic batteries are a key case. They will retailer extra power and cost quick, however they fail after just a few cycles. A skinny layer types on the anode throughout the first cycle. It lets lithium ions move and blocks electrons. This layer controls battery life and security. To look at it, researchers use X-ray photoelectron spectroscopy. Customary XPS is completed at room temperature in a vacuum. Below these situations the layer composition adjustments and turns into thinner, so the software overwrites what it’s alleged to learn.

A Stanford staff modified how the identical technique is used. They froze battery samples proper after the layer fashioned at −200 °C. They then examined the layer at about −110 °C utilizing XPS. Below these chilly situations the layer remained unchanged. Utilizing each commonplace XPS and the frozen model referred to as cryo XPS, the staff studied how batteries carry out with totally different electrolytes. Customary XPS gave weak hyperlinks between the chemistry of the layer and battery efficiency. Cryo XPS gave sturdy hyperlinks. This implies the frozen technique yields knowledge that higher displays the actual state of the interface throughout operation.

In addition they noticed that commonplace XPS alerts can mislead battery design. Customary XPS confirmed excessive lithium fluoride within the layer, which is linked to longer battery life. Cryo XPS confirmed a lot much less. The identical mismatch appeared with lithium oxide. This means that some previous design decisions could relaxation on distorted knowledge.

Lithium metallic batteries have excessive power potential however endure from security and life cycle points that come from this skinny protecting layer. With a extra correct view of what the layer incorporates throughout use, researchers can design higher electrolytes or coatings to stabilize it. The work additionally calls into query previous interpretations made utilizing room temperature XPS. The cryo technique offers a extra trustworthy image and will assist progress in different batteries and in unrelated supplies the place the probe itself adjustments what’s measured.