Convert an affordable air fryer right into a high-performance 3D printer filament dryer

— October twenty fourth, 2025

Submit a few 3D printing drawback — any 3D printing drawback — on-line and all the highest feedback will probably be: “Is your filament dry?” That could be a prudent query to ask, as a result of filament that has absorbed moisture will wreak havoc on print high quality and might even trigger complete print failure. If you wish to maintain your plastic good and moisture-free on a funds, then try Milos Rasic’s element14 mission on changing a $10 air fryer right into a 3D printer filament dryer.

There are many devoted filament dryers in the marketplace and so they aren’t significantly costly. However in addition they aren’t sophisticated and it’s simple to construct one with some parts out of your elements bin and an affordable air fryer from a thrift retailer.

Filament dryers work by heating and circulating air. Some use desiccant to extend passive drying, however the heating course of alone is sufficient to attract moisture out of filament. An air fryer already has a heating parts and followers for air circulation, so Rasic simply wanted to manage them with a suggestions loop from a temperature sensor.

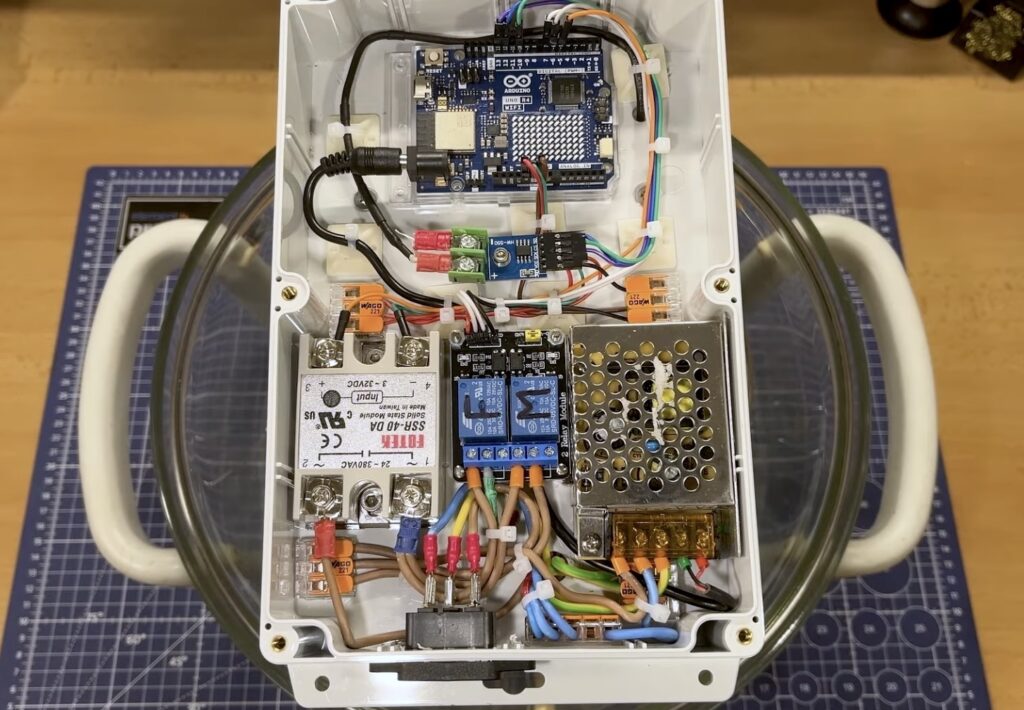

He used an Arduino UNO R4 WiFi board, which controls the 220V fan and heater via a trio of relays: one grasp relay, one relay for the fan, and one solid-state relay (SSR) for the heating component. The Arduino screens temperature via a DFRobot DFR0558 temperature sensor.

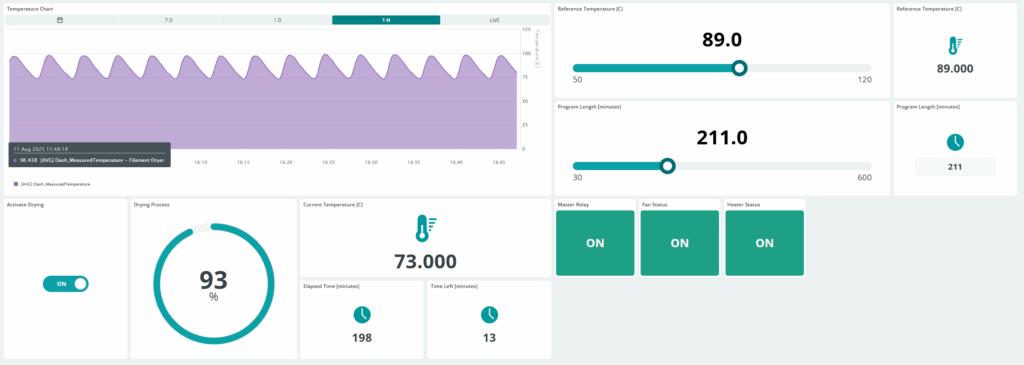

Rasic then constructed a web-based person interface with the Arduino Cloud, so he can run drying jobs and see standing data at any time.

One main advantage of this setup is that it might get very popular and can simply exceed 90°C. Many low-cost filament dryers received’t go over 60°C, in order that’s an enormous benefit for folks working with cussed filament that’s reluctant to launch moisture.