Robots that plan in seconds, adapt on the fly and work in sync. This AI may change how factories run. Learn extra!

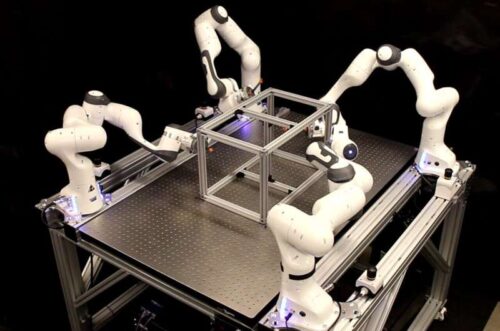

Scientists at UCL, Google DeepMind, and Intrinsic have developed an AI system referred to as RoboBallet that permits teams of robotic arms to coordinate actions quicker than real-time. The system may enable factories to adapt if a robotic fails or if the structure modifications, whereas additionally serving to producers optimize robotic placement for effectivity and throughput.

RoboBallet is designed for meeting strains and manufacturing unit flooring, the place a number of robots share areas with obstacles. It automates the planning of robotic actions, a job that’s presently dealt with manually by specialists and might take tons of of hours. With RoboBallet, motion plans are generated in seconds.

A key function of the system is scalability. Conventional planning algorithms battle when various robots are concerned as a result of complexity grows. RoboBallet makes use of a graph neural community mixed with reinforcement studying (RL). This enables the system to be taught coordination methods as an alternative of memorizing layouts, making it appropriate for large-scale industrial use.

In reinforcement studying, RoboBallet learns by trial and error, receiving rewards when duties are accomplished, with larger rewards for quicker completion. The graph neural community allows robots to deal with obstacles and different robots as nodes in a community, serving to them plan their actions.

In accordance with a analysis paper printed in Science Robotics, RoboBallet skilled for a couple of days earlier than it was in a position to produce plans in seconds. It managed as much as 40 duties with eight robotic arms in layouts it had not seen earlier than.

The system has potential purposes in automobile manufacturing, electronics meeting, and robotic building, particularly in settings the place robots should work shut collectively.

At current, RoboBallet focuses on reaching duties, reminiscent of transferring an arm to some extent for welding. Future variations may prolong to operations like pick-and-place, portray, and managing job order. Researchers additionally intention to adapt it for robotic groups with completely different features and extra complicated obstacles.

RoboBallet doesn’t but deal with each manufacturing unit case, reminiscent of duties that should observe a set sequence or robots with completely different talents. Its structure is designed to assist these options in future updates.