Mass market T-shirts journey greater than most People do. The supplies in them generally journey tens of hundreds of miles from their cotton area roots to retail racks.

Lower than 5 % of garments purchased in the US are made right here, as 1.5 million jobs in attire and textiles disappeared between 1979 and 2019.

Those that dream of renewed, home-grown provide chains have grasped for brilliant spots within the Trump administration’s chaotic storm of tariffs which have made it inconceivable for corporations to conduct enterprise as normal. Some advocates of gradual vogue have discovered hope within the White Home’s closure of a duty-free customs loophole that had favored fly-by-night quick fashions like Shein’s.

The secondhand clothes market could also be an early beneficiary of such insurance policies, however what concerning the few corporations already making garments from scratch domestically?

If anybody can reply that query, it’s T-shirt maker Eric Henry. His purpose-driven mission to supply near residence has saved his Burlington, North Carolina, enterprise afloat because the late Nineteen Seventies. In 1994, nevertheless, the North American Free Commerce Settlement (NAFTA) nearly broke his wholesale screen-printing outfit TS Designs, as prospects like Nike bailed for cheaper suppliers abroad.

Native farm-to-fashion

As a substitute of collapsing, Henry drove tougher right into a sustainability area of interest, launching a Cotton of the Carolinas challenge that fosters “mini provide chains.” Through the COVID-19 pandemic, he expanded that work right into a retail model, Strong State Clothes, to advertise pure fibers and dyes derived from walnuts and marigolds. Scanning a QR code on the garment label opens a web site of the faces, places and get in touch with particulars for every cotton farmer, fiber spinner and stitching operation.

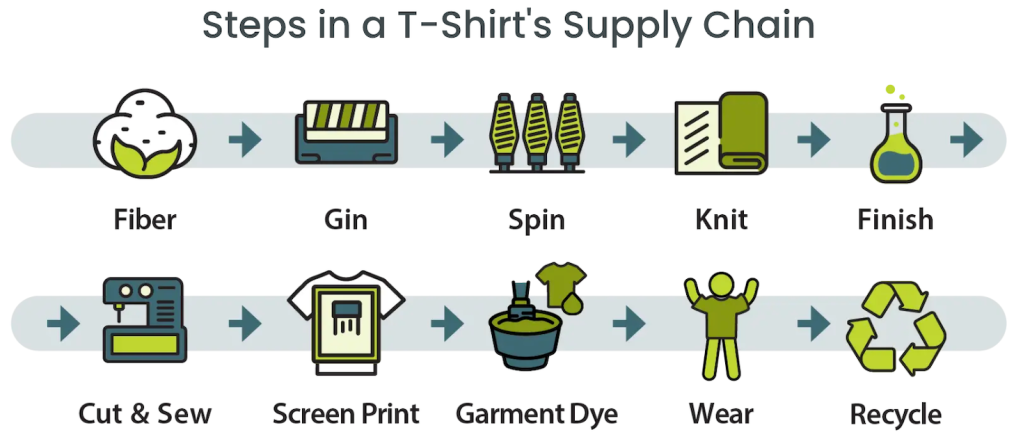

“I need to know the farmer,” mentioned Henry, who has launched a collective of small farmers, of his new The place Your Clothes web site. “I need to know the gin. I need to know specifics, as a result of our trade is so good at greenwashing. It’s a approach that we we verify ourselves, and the patron checks us.”

However a long time into his labors to advance “grime to shirt” manufacturing within the Southeast, Henry mentioned hyper-fast vogue has introduced the hardest challenges since NAFTA. And the powers-that-be in Washington are stripping away the helps that might assist corporations to revive U.S. manufacturing, and particularly sustainable practices, in response to Henry.

“On the finish of the day, income are essential,” Henry mentioned. “Earning money is essential. However I don’t need to do this if I’m hurting folks or the planet.”

He has spent the higher a part of 2025 making an attempt to make sense of seesawing tariffs as a way to afford the Spanish tools he must construct “the garment dye home of the long run.” In the meantime, federal funding for farmers’ sustainability and climate-related efforts is very unsure, with many packages delayed, canceled or in danger, impacting each Henry’s enterprise and the broader provide chain.

“It simply causes additional chaos within the market,” he mentioned. As well as, Henry fears that farmers who already promote cotton overseas at a loss will wrestle to draw patrons, as a result of tariff “sledgehammer.”

Doubling down

Nonetheless, Henry is doubling down on his goal. He desires to disrupt attire manufacturers’ sourcing by rising a producing cluster within the Southeast. He insists that environment friendly, localized manufacturing will justify the worth premium of his $50 tees for company patrons.

“Let’s discuss concerning the attire that you simply make that you simply by no means promote,” he mentioned he’ll inform manufacturers. “Let’s discuss concerning the attire that you simply make that you simply mark down. Let’s discuss how when one thing occurs within the market it takes you six months to reply. I can reply in every week.”

Native challenges

Henry provides an unusually granular degree of transparency, however he isn’t the one maker pushing a U.S. farm-to-fashion mannequin. American Large of San Francisco sells its “Biggest American T-shirt,” spun from North Carolina cotton, for $65.

Imogene + Willie spent 4 years bringing to life T-shirts sourced and crafted inside 400 miles of Nashville. The $56 white or black shirts are the fruits of its Cotton Mission, which concerned a seventh-generation farmer in Alabama, a third-generation spinner in North Carolina and a social enterprise garment store in Tennessee.

And this fall, Renaissance Fiber of Winston-Salem, North Carolina, will begin transport its first-edition $55 hemp shirt, which is farmed in Montana and refined and knitted within the Carolinas.

“Every shirt is a wearable piece of historical past, a testomony to American innovation, and a blueprint for a extra resilient, sustainable and American-made future,” the corporate’s web site states. The imaginative and prescient is romantic. In actuality, native producers face quite a few disadvantages relative to a company operation with in-house capabilities and shock-absorption capability at scale.

Take into account Henry’s newest year-long cycle to supply a batch of roughly 1,000 shirts inside 800 miles from residence. It begins in spring, with seedlings planted by the Texas Natural Cotton Cooperative — maybe the final natural cotton producer within the nation. A close-by ginning operation then eliminated the seeds.

Ordinarily, Henry could have turned to the most important cotton spinner within the U.S., however Hurricane Helene worn out the North Carolina firm’s final home facility in 2024.

“Then the massive cloth finisher, Carolina Cotton Works, in a 30-day discover went out of enterprise final yr and knocked a giant gap in what we’re making an attempt to do,” Henry mentioned. Fortuitously, the close by spinner Henry selected, Beverly Knits, had snapped up a ending operation simply 60 miles from his workplace — along with proudly owning textile finisher Hemingway Attire in South Carolina.

“Finally, we want the manufacturers; they’ve the retail channels,” he mentioned. “However we will make attire manufacturing viable on this nation, doing it this completely different approach.”

Can extra tight-knit, localized provide chains reach the US? Or are these dirt-to-shirt efforts destined to be boutique manufacturers that may solely serve shoppers who can afford 10 occasions the worth of a mall or Amazon tee?

A threadbare trade

Margaret Bishop, a professor on the Parsons Faculty of Design, is pessimistic about prospects for a significant revival of textile manufacturing on this nation.

“Fifteen years in the past, I mentioned we may nonetheless efficiently manufacture in the US,” she mentioned. “I now not consider that we will on any vital scale.”

People typically don’t need to work in humid dye retailers or mills, she mentioned. And along with tariffs, the White Home’s crackdown on undocumented employees is making even authorized immigrants fearful to come back to work in attire jobs, she added.

Furthermore, offering the number of yarns and materials essential to sustain with seasonal fashions requires the form of specialization that now not exists within the U.S.

“We don’t have the big fiber producers, the big weaving mills, the big knitting mills,” Bishop mentioned. “We’ve outsourced it abroad.”

Nonetheless, Bishop mentioned, there could also be home alternatives to supply particular items such T-shirts, denim and specialised uniforms.

Regional manufacturing websites

Gray Matter Ideas, for instance, is eyeing the Southeastern U.S. to construct an AI-enabled manufacturing facility to churn out socks and ultimately T-shirts. The New York-based firm sells its fundamentals, together with undershirts and boxers, to manufacturers like Wrangler and DKNY.

The plant would provide roles for engineers and technicians with attire and manufacturing levels – a far cry from a sweatshop stereotype, in response to Robert Antoshak, vp of world sourcing. “I’ve this advertising picture of individuals strolling round in white lab coats: ‘Take a look at our socks, have a look at our underwear, our T-shirts.’”

Increasing some home manufacturing would convey sustainability advantages, in response to Antoshak. For instance, home cotton is simpler to hint. “We are able to actually inform a dirt-to-shirt story that’s U.S.-manufactured and -grown,” he mentioned.

Along with the momentum behind homegrown, pure fiber shirts, efforts are taking root to create round manufacturing hubs for polyester. Goodwill Industries Worldwide of Rockville, Maryland, is partnering with polyester recycling enterprise Reju to provide secondhand vogue waste to rework into new textiles.

Mentioned Goodwill CEO Steve Preston: “To the extent that we’ve these recycling amenities constructed right here, it is probably not that huge of a step then to develop in that very same area individuals who can spin that into yarn, fairly than promoting it and sending it to the opposite aspect of the world.”