3-phase BLDC motor management to a compact, high-performance type issue utilizing GaN FETs for 48 V techniques.

Environment friendly Energy Conversion (EPC) has launched a brand new high-performance reference design geared toward reworking how engineers strategy 3-phase BLDC (brushless DC) motor management. The analysis board integrates gallium nitride (GaN) FET expertise right into a compact, environment friendly platform optimized for 48 V motor techniques, making it preferrred for robotics, drones, e-bikes, and industrial automation.

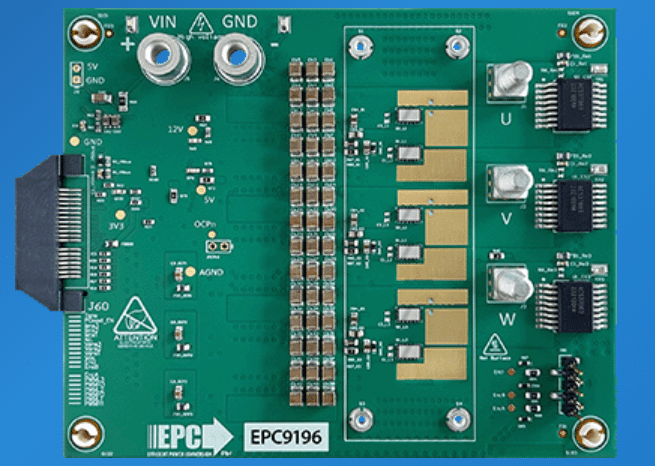

On the coronary heart of the EPC9196 is a set of six EPC23102 built-in GaN half-bridge FETs. These gadgets mix ultra-low RDS(on), quick switching, and high-frequency efficiency in a thermally environment friendly, low-inductance bundle. The end result: diminished losses, minimal lifeless time, and near-silent motor operation—even at excessive speeds.

The important thing options are:

- Helps section currents as much as 50 A (20 ARMS steady)

- Handles bus voltages from 20 V to 80 V

- Appropriate for a variety of motor purposes

- Constructed-in protections:Underneath-voltage lockout, Over-temperature shutdown, Fault reporting for secure operation

- Designed for strong, dependable efficiency in demanding situations

Designed with system integration in thoughts, it contains the Microchip dsPIC33CK-based controller on the companion EPC9147 controller board, enabling sensorless FOC (field-oriented management) of BLDC motors with real-time pace and torque suggestions. This helps builders rapidly implement superior management algorithms and get their purposes working sooner.

It has mixture of excessive energy density and ease of use. Regardless of its compact footprint (130 mm x 100 mm), it options optimized structure and thermal administration, minimizing parasitic results and maximizing effectivity. Whether or not you’re prototyping next-gen motor drives or benchmarking GaN in opposition to silicon MOSFETs, the board affords a quick path to high-performance design.

It’s an entire improvement platform for engineers able to discover some great benefits of GaN in real-world motor management techniques. With rising demand for high-efficiency, light-weight, and compact energy options, EPC’s GaN-based motor drive platform affords a glimpse into the way forward for movement management design.