What sorts of jobs are rising from the large investments in India’s semiconductor trade? Do we now have the expertise to satisfy this demand? If not, how are the federal government, academia, and trade addressing the hole—and the way can these efforts be accelerated to construct the best expertise quicker? To discover these questions, EFY’s Rahul Chopra had the chance to talk with Dr Ashwini Ok Aggarwal, a seasoned chief who has worn many hats inside the semiconductor ecosystem. Here’s what he shared.

Q. What sort of job alternatives or profession alternatives are rising now due to the expansion within the semiconductor sector and all of the investments occurring?

A. The semiconductor trade in India is reaching an inflection level. With main mega and giga initiatives introduced, we’re seeing investments of near ₹150 billion being applied. Tata’s fab is progressing at an amazing tempo. Tasks from firms corresponding to Kaynes, Micron, CG Semi, and lots of smaller gamers are additionally taking form.

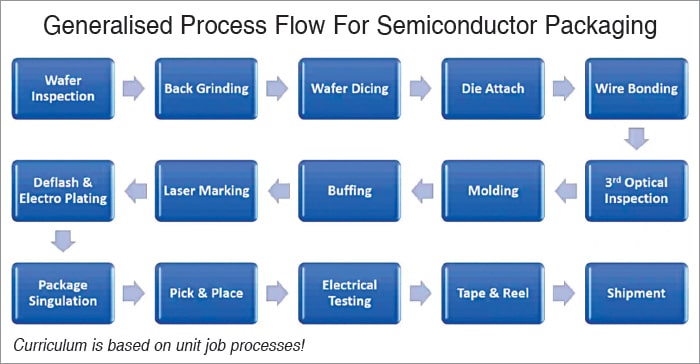

As this unfolds, it’s inevitable that India might want to develop manufacturing expertise. Whereas India has lengthy been designing chips, we now must design our future within the ‘Make in India’ period. Careers are evolving, and we’re seeing rising demand for expert professionals throughout all the ecosystem, not simply at fabs however all through the worth chain.

Q. Are you able to give some examples of the sorts of jobs being created?

A. Let me quote the CEO of Utilized Supplies. In a gathering, he as soon as mentioned, “I want I had individuals who knew atomic layer deposition or may perceive plasma engineering within the nation; I might give 10 job letters on the spot.”

Design stays key, little doubt. However we are actually finishing the circle with manufacturing. A fab, as a course of trade, requires greater than electronics engineers—it additionally wants mechanical, supplies, chemical, pc, electrical, and EHS (setting, well being, and security) engineers.

Every of those disciplines performs an important function in enabling the profitable operation of a fab. Along with technical roles, there’s a important demand for professionals in well being and security. Specialists who handle hazardous chemical compounds and manufacturing facility operations are important. These expertise are additionally extremely transferable. An industrial security engineer skilled in semiconductor manufacturing can work within the chemical sector or tackle roles overseas.

Q. What different forms of items are rising to help the semiconductor ecosystem in India?

A. Utilized Supplies and Lam Analysis have each introduced main investments. Utilized Supplies started with a $400 million venture in India. They’ve already acquired a ₹3.5 billion land parcel in Bengaluru to construct a provider and check ecosystem. That is prompting their international provide chain companions to take India critically. As an illustration, Rockwell Automation has introduced a $66 million venture in Chennai to construct clever energy techniques for Utilized’s international tools. That is only one instance; comparable developments are additionally going down with different firms.

Fabs additionally want speciality gases, bulk gases, ultra-pure water, sensors, and rather more. Water know-how turns into particularly important, precision in each drop results in revenue in each wafer. Even cleanroom creation and upkeep are specialised engineering capabilities.

| Dr Ashwini Ok Aggarwal is at present a Professor of Apply at Manav Rachna Worldwide Institute of Analysis & Research (Faridabad/Delhi NCR); Sr Member IEEE; Founder Chair IEEE EPS, Delhi-NCR Chapter. He’s additionally the Nation Advisor of Society for Info Show. He has over 42 years of trade expertise – over a decade at Utilized Supplies—a world chief in Semiconductor Gear. He has co-authored the AICTE curriculum for Semiconductor manufacturing electives and is the chair of the Semiconductor manufacturing ability committee at Electronics Sector Ability COuncil. He’s additionally the chair of the manufacturing expertise committee for semiconductor packaging beneath MEITY-ISM advisor (packaging). |

Q. May you elaborate extra on the engineering behind fabs? What precisely occurs beneath the cleanroom?

A. Positive. The actual engineering fantastic thing about a fab lies within the sub-fab, which is situated under the cleanroom. That is the place utility feeds, fuel pipelines, security techniques, and abatement techniques are put in. It entails extraordinarily detailed industrial engineering. Even earlier than building begins, industrial engineers should map out the piping, feeds, sensor placements, scrubbers, and extra. Each ingredient should be pre-designed to make sure security and maximise yield. It goes far past utilizing EDA instruments; precision engineering is required to construct the infrastructure itself.

Q. How do you see India overcoming the problem of making new ability units, updating curriculums, and exposing college students to new tools and instruments?

Oops! That is an EFY++ article, which suggests it is our Premium Content material. That you must be a Registered Consumer of our web site to learn its full content material.

Good Information: You’ll be able to register to our web site for FREE! CLICK HERE to register now.

Already a registered member? If YES, then merely login to you account under. (TIP: Use ‘forgot password’ function and reset and save your new password in your browser, should you forgot the final one!)