3D Methods, the U.S.-based 3D printing pioneer headquartered in Rock Hill, South Carolina, has unveiled a trio of application-specific options at RAPID + TCT 2025 aimed toward remodeling manufacturing effectivity. The announcement contains the brand new Determine 4 135 platform for high-mix, low-volume manufacturing, a process-optimizing module for EXT Titan Pellet printers, and QuickCast Diamond, a construct model for precision funding casting patterns utilizing the PSLA 270 SLA system.

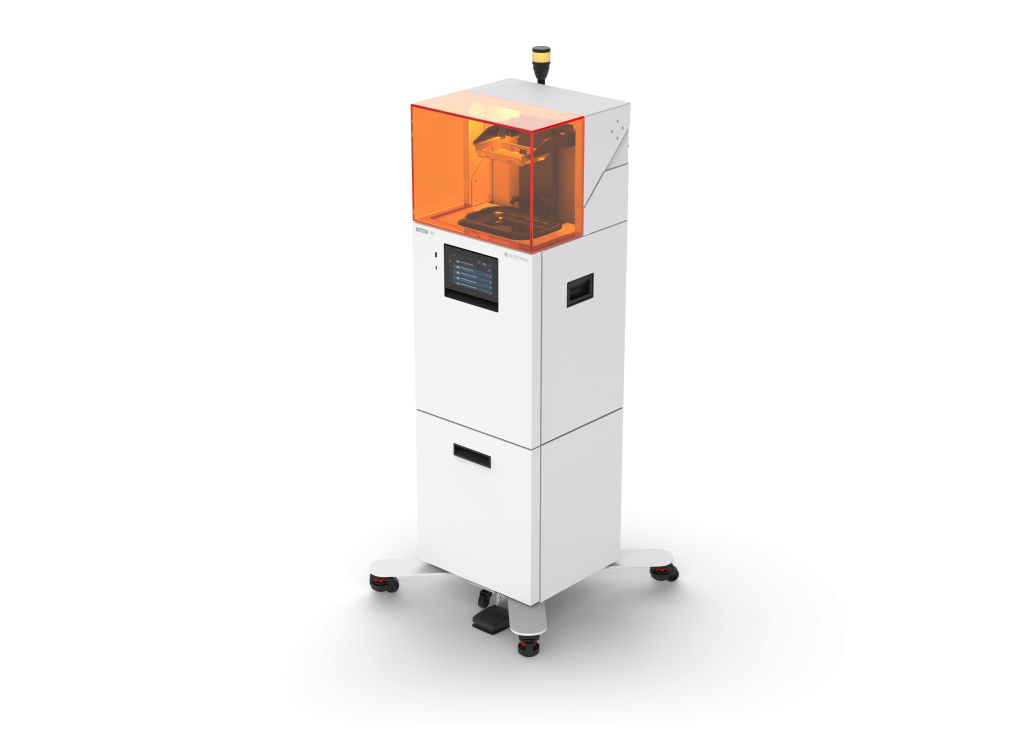

Versatile precision manufacturing with Determine 4 135

The Determine 4 135 system is engineered to handle the rising demand for HMLV workflows in industries resembling motorsports, furnishings, electronics, and healthcare. Conventional injection molding is cost-effective solely at scale and requires devoted tooling for every half variant. In contrast, the Determine 4 135 permits speedy half manufacturing with out tooling, supporting tons of of half variations at excessive throughput and considerably decrease price.

The platform is paired with Determine 4 Powerful 75C FR Black, a flame-retardant materials rated UL94 V0 at skinny wall sections (0.4 mm) with long-term thermal resistance of as much as 150°C (electrical) and 130°C (mechanical). In response to 3D Methods, this mix permits customers to fabricate exact, production-grade components resembling electrical connectors, medical enclosures, and customized furnishings {hardware} with repeatable high quality and minimal post-processing.

By leveraging projector-based stereolithography and a excessive course of functionality index (CpK > 1.33), the Determine 4 135 is positioned to complement and even change injection mould tooling in demanding functions the place accuracy, velocity, and traceability are required.

Enhancing pellet extrusion effectivity with real-time management

For big-format and industrial-scale polymer functions, 3D Methods has launched a brand new patent-pending module for its EXT Titan Pellet 1070 and 1270 printers. The add-on contains two essential options; Half Solidity Optimization, which actively adjusts the extrusion circulate fee to cut back voids and inconsistencies, bettering inner half density and chopping machining time by as much as 50%; and Print Mattress Mapping, which Scans and maps the construct floor in beneath 60 seconds, making a numeric top map to information leveling. This will cut back leveling time by 60% in comparison with prior strategies.

The module is designed for additive manufacturing environments the place EXT Titan printers are used to create jigs, fixtures, tooling, and manufacturing components. It can ship customary on new EXT Titan Pellet methods with the elective milling spindle toolhead, and might be field-installable on present machines beginning Q3 2025.

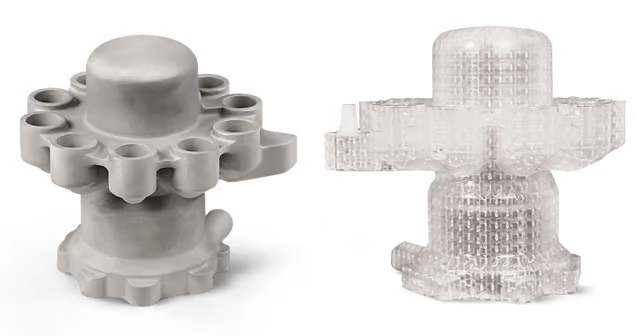

Accelerating funding casting with QuickCast Diamond

QuickCast, first launched by 3D Methods within the Nineteen Nineties, helped set up 3D printing as a priceless device in funding casting workflows. Now, the corporate has enhanced this functionality with QuickCast Diamond, a brand new construct model for its PSLA 270 printer that mixes SLA precision with the excessive throughput and materials flexibility of its Determine 4 methods.

Used to supply grasp patterns for steel casting in sectors like aerospace and power, QuickCast Diamond permits the speedy design of sacrificial constructions with glorious floor end and no geometric limitations. When processed by means of 3D Methods’ 3D Dash software program, the PSLA 270 can rapidly ship mid-sized casting timber at a fraction of the time and price of conventional tooling.

This function goals to additional cut back time-to-part and cost-per-part for producers producing turbine blades, automotive impellers, and related geometrically advanced components.

Dr. Jeffrey Graves, president & CEO, 3D Methods, emphasised the strategic nature of the releases, stating:

“Our historic R&D surge in 2024 yielded dozens of polymer and steel merchandise, all pushed by a rising demand to handle an growing variety of functions utilizing additive manufacturing. These new product introductions underscore our unwavering dedication to delivering application-specific options that handle our clients’ quickly evolving wants.”

Adoption of high-mix, low-volume manufacturing

The additive manufacturing business is more and more pivoting towards HMLV manufacturing as corporations search extra agile methods to answer market variability, half customization, and provide chain challenges. Current interviews with business leaders, together with HLH Speedy, spotlight how producers are adopting AM to bridge the hole between prototyping and scaled manufacturing with out sacrificing velocity or high quality. Government surveys revealed by 3D Printing Trade additionally verify that flexibility, velocity to market, and application-specific options are high priorities heading into 2025. In opposition to this backdrop, 3D Methods’ newest options replicate an ongoing shift towards AM platforms that may ship precision, repeatability, and price effectivity throughout diversified product portfolios.

What 3D printing developments do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the newest 3D printing information.

It’s also possible to comply with us on LinkedIn and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals 3D Methods EXT 1070 Titan Pellet 3D printer. Picture by way of 3D Methods.