The fiber does digital work after which breaks down in soil. It might assist scale back waste from garments and different wearable units.

Researchers at Seoul Nationwide College have developed a sort of fiber that works like digital supplies however breaks down after use. It features throughout its life after which degrades in soil or enzyme-rich environments, leaving no waste. The aim is to scale back the issue of digital textile waste.

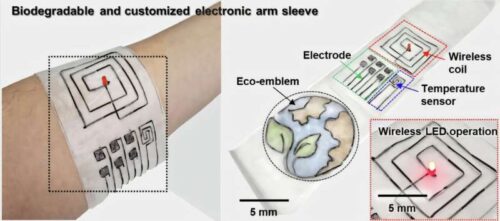

The staff examined this fiber by constructing a sleeve. The sleeve included a temperature sensor, EMG electrodes, and a wi-fi energy coil. It labored throughout motion and underneath completely different environmental circumstances. As soon as now not used, the sleeve—together with an embroidered image—started to interrupt down and decomposed in just a few months.

The fiber reveals efficiency with electrical conductivity round 2,500 S/m. It may well stretch as much as 38% with out breaking, face up to over 20 wash cycles, and survive greater than 5,000 bends. These options match or exceed many present e-textile supplies. The fiber can also be suitable with dry-jet wet-spinning, a course of that allowed the staff to supply over 10 meters in a single run.

The fiber is made by combining tungsten microparticles with a polymer referred to as PBAT (poly(butylene adipate-co-terephthalate)), making a conductive core. It’s then coated with an outer layer produced from polyanhydride (PBTPA), which gives power whereas nonetheless permitting the fiber to interrupt down.

This growth provides a doable strategy to take care of waste from wearable units. Matching a tool’s life with its use can result in new choices in patches, uniforms, sensors, and healthcare techniques.

The analysis brings collectively biodegradability, power, and manufacturing. Future work will give attention to including reminiscence and logic to help extra units. The staff can also be exploring “triggerable” degradation—designing supplies that break down in response to indicators like gentle, warmth, or pH, permitting for lifespans based mostly on use.

Annually, the world generates over 92 million tons of textile waste, a lot of it from supplies that don’t break down. With extra use of wearable electronics—similar to watches, bands, and clothes with sensors—the issue turns into extra advanced. E-textiles usually comprise steel wires, plastic layers, adhesives, and circuits, making them laborious to recycle.

This analysis reveals it’s doable to construct wearable units that may additionally return to the surroundings after use.