Researchers from Zhejiang College and Taizhou College have developed 3D printed bone fixation implants that mix structural help with focused antibiotic supply.

Led by Liwen Zhang, the workforce used stereolithography (SLA) to manufacture personalized bone nails created from dental resin composites infused with ceftriaxone sodium, an antibiotic generally used to stop infections throughout surgical procedure.

Orthopaedic implants utilized in bone restore are sometimes restricted by poor biocompatibility or a scarcity of therapeutic perform. Printed in Nature Scientific Experiences, this research addresses each points by introducing an implant that not solely helps therapeutic bone but additionally helps management an infection on the website. Fabricated utilizing commercially out there Anycubic Photon and Mono X 3D printers, the design highlights the potential of accessible, customizable manufacturing in medical settings.

Combining construction with drug supply

To construct the implants, the workforce first developed a customized resin formulation. They blended ethoxylated bisphenol A dimethacrylate (BPA2EODMA) with triethylene glycol dimethacrylate (TEGDMA) in a 7:3 ratio, an optimum combine for power and printability. The formulation included 1% TPO photoinitiator to allow UV curing.

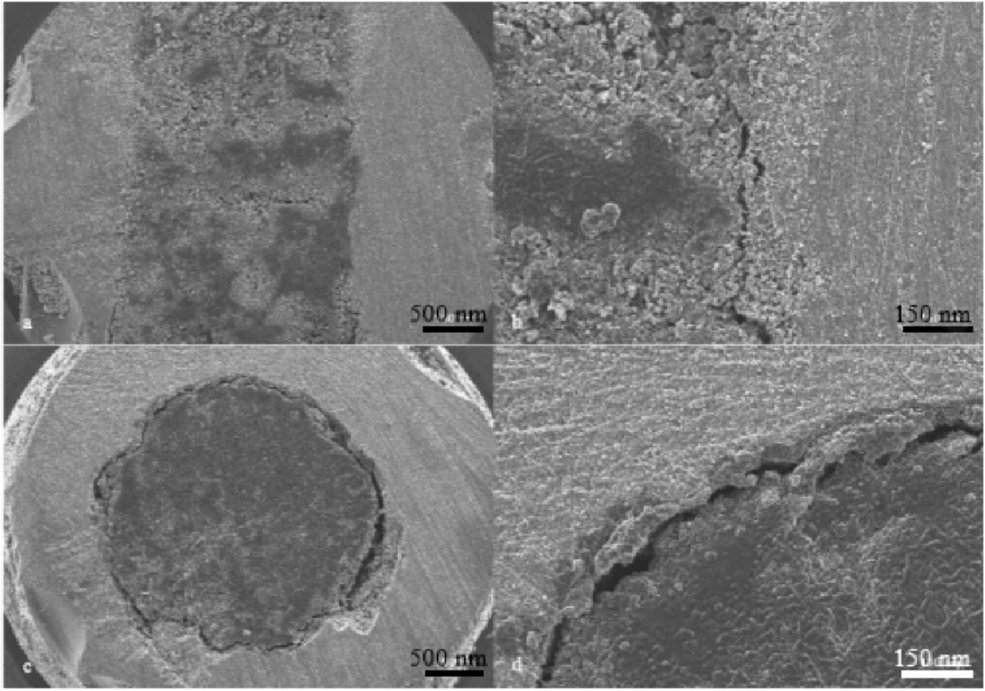

Utilizing SolidWorks software program, the researchers designed the implants and printed them at a decision of fifty microns, layer by layer. After printing, the components had been post-cured to make sure full hardening. Electron microscope photographs confirmed a dense, strong outer layer for mechanical power, whereas the within remained porous, good for storing and slowly releasing the antibiotic.

Exams revealed that the implants might deal with forces inside the vary required for non-load-bearing bone repairs, reminiscent of within the face or cranium. The implants had been additionally examined with three totally different antibiotic concentrations (1%, 5%, and 10%), utilizing polyethylene glycol (PEG) to assist distribute the drug inside the resin. Decrease concentrations led to extra even dispersion, whereas increased ranges launched some crystal formation however didn’t damage efficiency.

Drug launch and antibacterial motion

In lab assessments, the drug launch adopted a two-stage sample: a fast launch within the first 24 hours, adopted by slower, sustained diffusion. On the highest focus, about 80% of the antibiotic was launched inside three days. The researchers additionally discovered that curing time throughout printing affected how shortly the drug was launched. Longer curing occasions created a denser floor, slowing down the discharge.

The implants had been examined in opposition to widespread pathogens together with Staphylococcus aureus, Escherichia coli, and Candida albicans. All confirmed a transparent antibacterial impact, inhibiting microbial development by roughly 50% inside eight hours.

To check how the implants carried out in a organic setting, the workforce uncovered L929 fibroblast cells to bacterial infections. The drug-loaded implants helped the cells survive at charges much like these seen with direct antibiotic software.

Even at full-strength extract concentrations, the implants maintained over 70% cell viability in cytotoxicity assessments, assembly ISO 10993-5 requirements. Though one element of the resin, TPO, may be poisonous in excessive doses, the low concentrations used and full curing course of appeared to mitigate any important threat.

Whereas the outcomes are promising, this research remains to be in its early levels. The implants haven’t been examined in residing organisms but, and extra work is required to see how they carry out over time and in real-world circumstances. Future analysis will concentrate on testing in animals, combining totally different medicine to enhance therapeutic, and discovering methods to stop antibiotic resistance.

Drug supply by way of implants

Drug supply by way of 3D printed implants presents improved management, focused launch, and patient-specific customization in comparison with typical strategies. Whereas not but mainstream, it’s an rising space of analysis with rising potential in fields reminiscent of most cancers remedy, orthopaedics, and an infection administration.

In step with this, researchers on the Southwest Analysis Institute (SwRI) and the College of Texas at San Antonio (UTSA) developed a 3D printed implant designed to ship a managed dose of remedy over a number of weeks. Constituted of biodegradable supplies, the implant step by step dissolved after remedy, eradicating the necessity for surgical elimination.

It was meant to deal with circumstances reminiscent of infections, most cancers, arthritis, and AIDS by releasing medicine immediately on the website, together with triggering localized immunotherapy for tumor response. By personalizing dosages and limiting systemic unintended effects, the system provided a focused different to each day remedy or intravenous remedies. Moreover, the undertaking was funded by the Join program.

Elsewhere, researchers at Queen’s College Belfast developed 4D printed breast implants utilizing good supplies that change form in response to physique circumstances like pH and temperature. Produced with a Cellink Bio X printer and a mix of carboxymethyl cellulose and cellulose nanocrystals, the implants had been loaded with the chemotherapy drug doxorubicin for localized drug launch.

Designed to increase and conform to a affected person’s tissue cavity, the implants improved match, aesthetic outcomes, and most cancers administration. Imaging instruments like MRI and CAT scans had been used to personalize the match, providing a extra tailor-made and fewer invasive strategy to breast most cancers care.

What 3D printing tendencies must you be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits SEM picture of 3D printed implants: (a) and (b) had been the vertical part view, (c) and (d) had been the cross part view. Picture by way of Zhejiang College.