UK-based engineering agency Renishaw has introduced a collaboration with Irish Manufacturing Analysis (IMR) at their facility close to Dublin to develop superior course of parameters for metallic 3D printing of freeform optical parts utilized in laser-based satellite tv for pc communications.

This mission, a part of a Disruptive Expertise Innovation Fund (DTIF) initiative led by freeform optics producer mBryonics, goals to facilitate the transition from conventional machining to near-net-shape 3D printing, accelerating manufacturing effectivity. The partnership is concentrating on completion by autumn 2026.

“Our collaboration with IMR is about extra than simply supplying know-how; it’s about offering the experience and assist wanted to drive innovation,” mentioned Chris Dimery, AM Enterprise Supervisor (EMEA) at Renishaw. “By working carefully with IMR, we’re making certain that superior additive manufacturing options are developed with real-world industrial adoption in thoughts.”

Be part of AM protection specialists on July tenth at Additive Manufacturing Benefit: Aerospace, Area & Protection. Areas are restricted for this free on-line occasion. Register now.

Scaling Manufacturing and Trade Collaboration

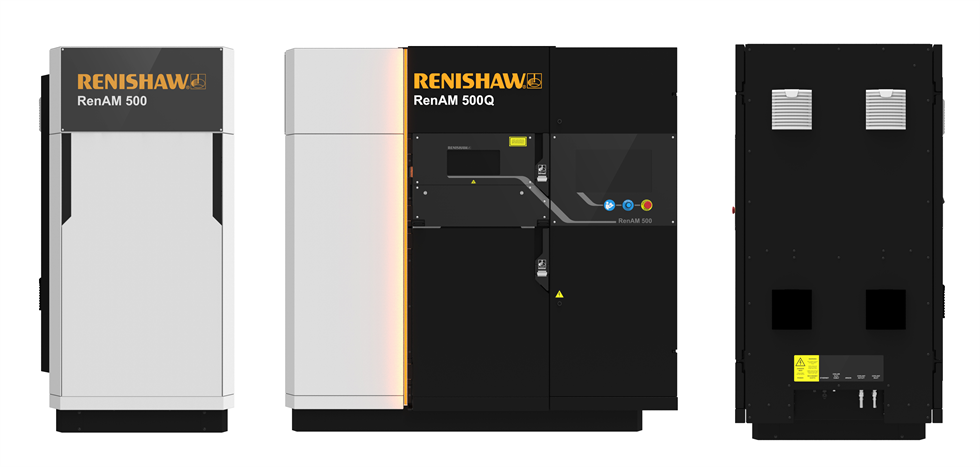

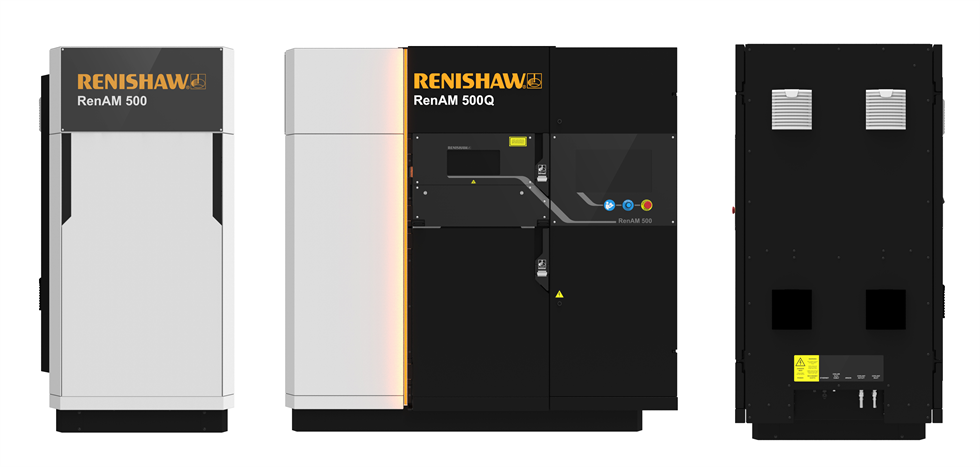

For this collaboration, IMR researchers chosen the Renishaw RenAM 500Q Flex system, a part of the RenAM 500 sequence. It options 4 500W lasers and presents both versatile or computerized powder and waste dealing with. With a 250 x 250 x 350 mm construct quantity, the system features a fuel circulation system, sealed vacuum chamber, and precision digital optics—designed to assist purposes starting from materials growth to scaled manufacturing. Its TEMPUS know-how additional enhances productiveness by means of superior course of management.

IMR researchers chosen this technique to handle the particular challenges of additively manufacturing temperature-sensitive aerospace supplies. In response to Renishaw, standard laser powder mattress fusion methods typically expertise thermal fluctuations, which might result in defects resembling cracking. The 500Q Flex’s multi-laser setup and course of stability assist mitigate these points by decreasing temperature variation and enabling quicker layer processing.

“Our method will enhance construct high quality and allow scalability,” mentioned Colin Meade, Additive Manufacturing Technologist at IMR. “This analysis isn’t nearly lab-based experimentation; it’s about growing know-how that’s prepared for full-scale manufacturing as shortly as doable. We have to attain a know-how readiness degree (TRL) of round seven or increased to make sure fast switch to business.” Meade added that this analysis may permit mBryonics to scale manufacturing from single-digit items monthly to a whole lot and even hundreds.

Strategic AM Partnerships with the RenAM 500Q Flex System

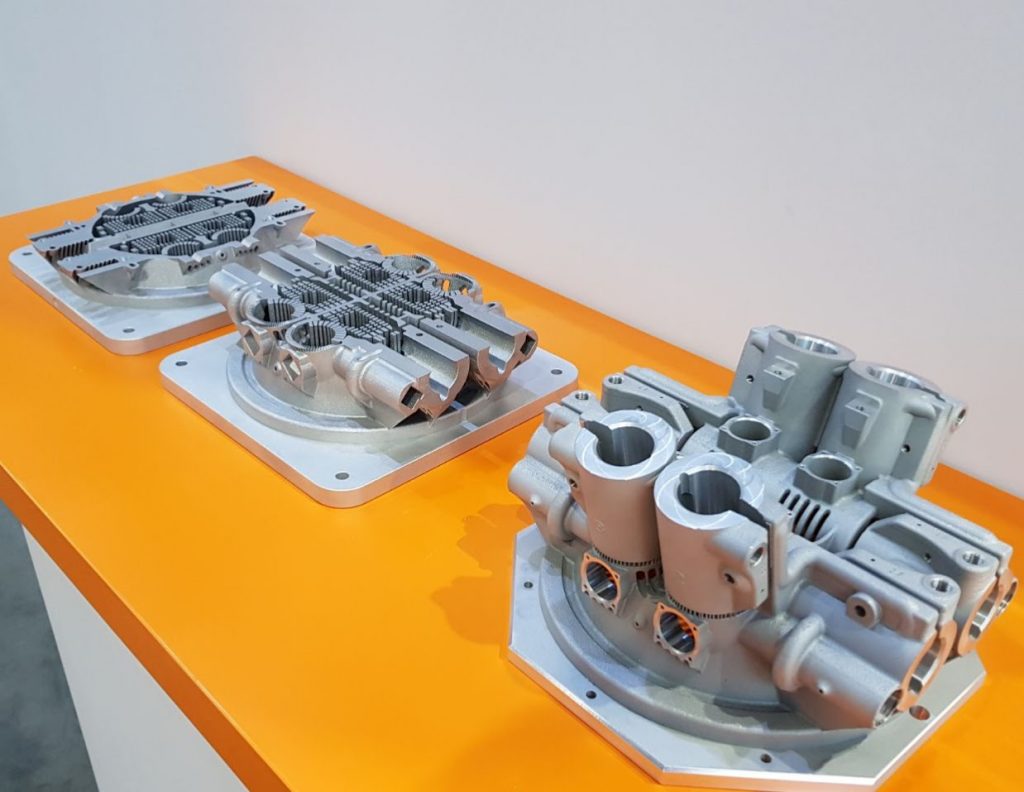

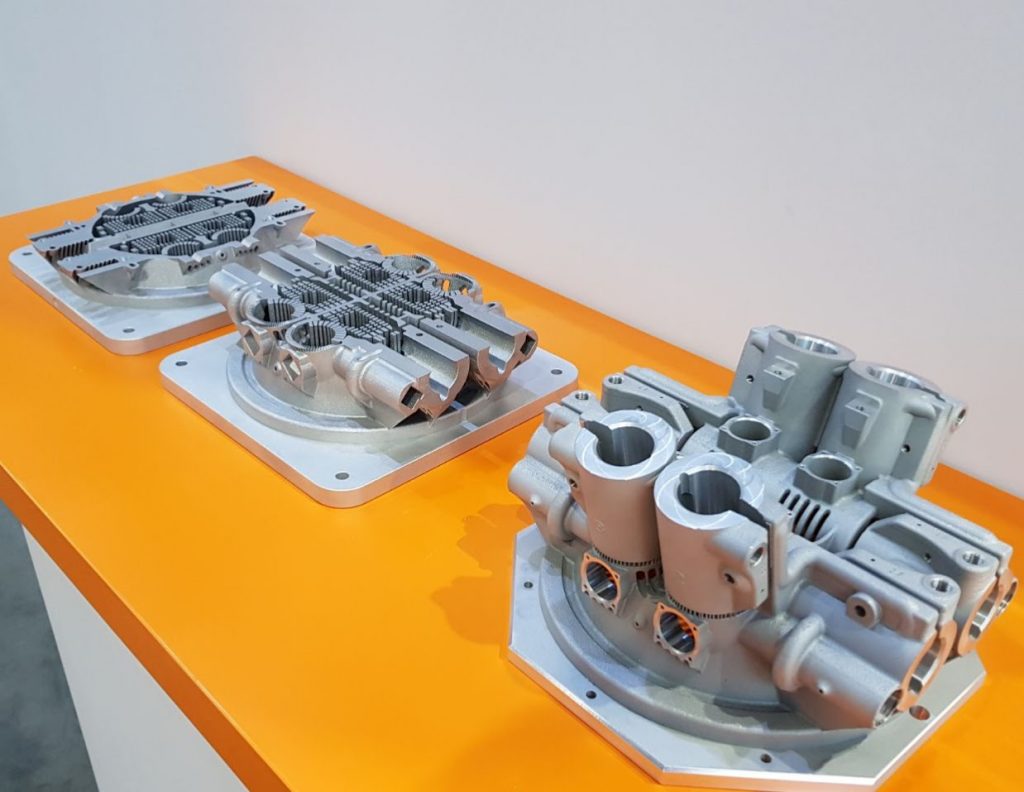

Via strategic partnerships, Renishaw has superior using its RenAM 500Q Flex system to streamline manufacturing processes and deal with sector-specific challenges. In 2023, KOSO Kent Introl (Kent Introl) partnered with Renishaw to discover how AM know-how advances the oil & fuel sector. By putting in Renishaw’s RenAM 500Q Flex system in West Yorkshire, Kent Introl turned the primary UK oil and fuel valve components producer to undertake AM know-how. Kent Introl goals to fulfill business calls for for brand spanking new options, power effectivity, and carbon emission discount, exploring AM’s potential partially design optimization and on-demand companies.

Renishaw additionally equipped its RenAM 500Q AM system to Domin, a fluid energy methods producer for growing extremely aggressive servo-proportional hydraulic valves utilizing 3D printing. Domin sought environmental sustainability, concentrating on a one gigatonne CO2e emissions discount by 2030. Using Steel AM, Domin aimed to design complicated buildings with excessive effectivity and diminished waste, combining additive manufacturing with trendy applied sciences to create modern hydraulic valves.

Be part of our Additive Manufacturing Benefit (AMAA) occasion on July tenth, the place AM leaders from Aerospace, Area, and Protection come collectively to share mission-critical insights. On-line and free to attend. Safe your spot now.

Who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to maintain up with the newest 3D printing information.

You may as well observe us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals Renishaw’s RenAM500 Q 3D printers. Picture by way of Renishaw.