New York-based IT multinational Worldwide Enterprise Machines Company (IBM) has patented a way for designing 3D printed buildings in digital actuality (VR).

The doc (US12340150B2) was initially filed in June 2021 and revealed in December 2022. Final week, the United States Patent and Trademark Workplace (USPTO) granted the patent, which means it’s now legally enforceable.

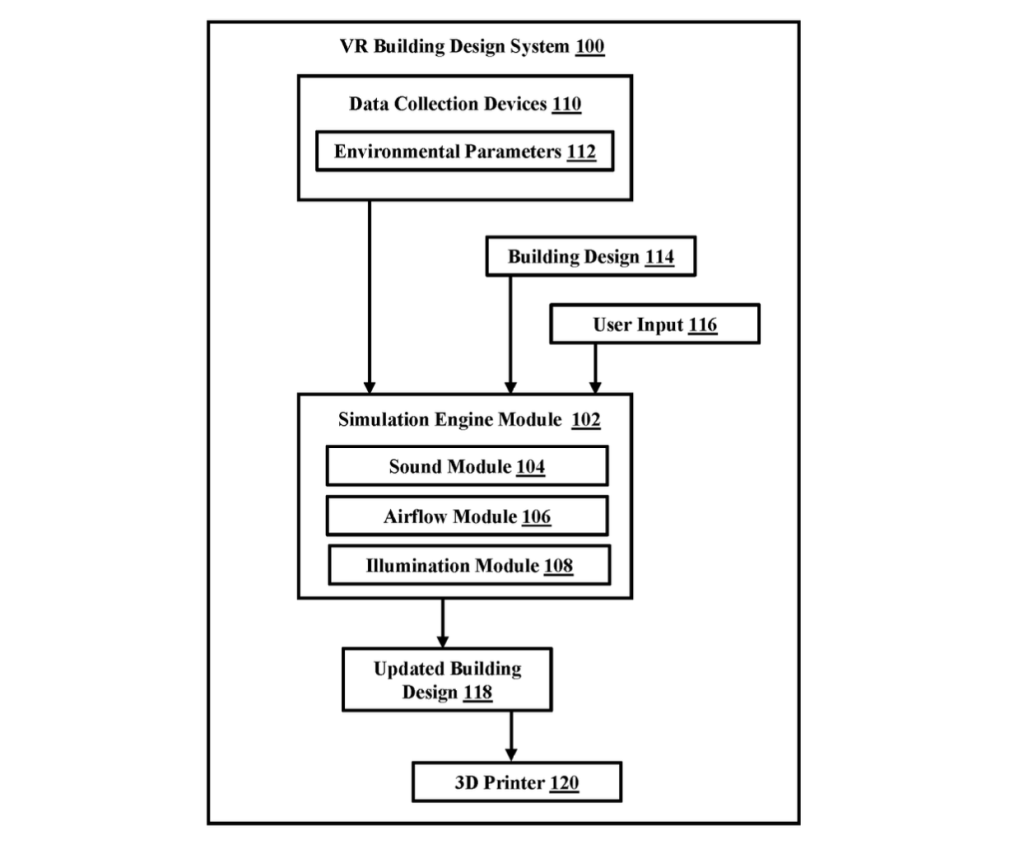

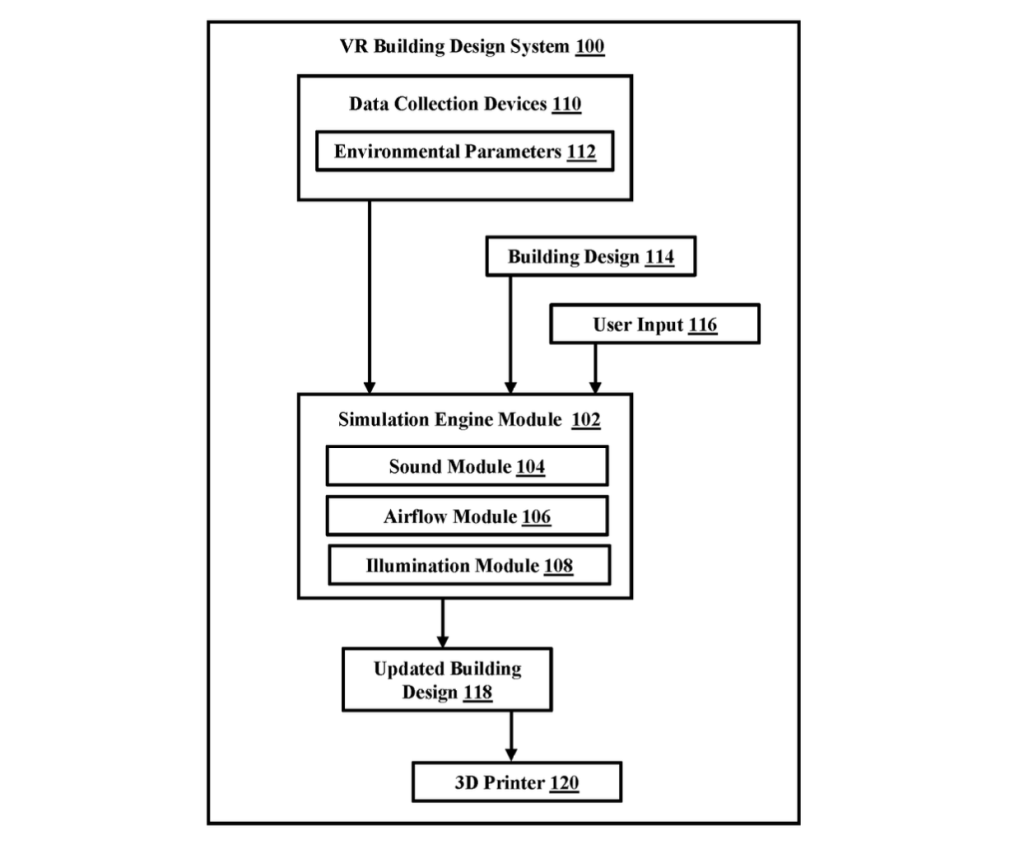

The patent outlines a course of that makes use of VR to simulate buildings earlier than they’re constructed. A simulation engine module replicates environmental components comparable to noise, airflow, lighting, and temperature, enabling customers to expertise how the constructing would really feel and performance in real-world situations.

Architects can request design changes, like noise-reducing supplies or repositioning home windows, which the system routinely generates and integrates into revised blueprints. As soon as finalized, the up to date design is distributed to a development 3D printer to manufacture the constructing.

In keeping with the patent, this course of allows extra user-centered constructing designs, enhancing performance and decreasing expensive post-construction adjustments. The doc claims that this method is particularly precious for 3D printed buildings, that are tough to change after fabrication.

IBM’s new patent extends past the development of residential buildings comparable to homes and condominium blocks. It explicitly applies to “any constructing or construction a consumer might wish to assemble in a specific geographical location.” Given the corporate’s emphasis on digital infrastructure and AI capabilities, this VR–3D printing course of might show precious in designing knowledge facilities. These complicated, large-scale amenities should meet strict temperature necessities because of their function in powering cloud companies, coaching superior AI fashions, and supporting edge computing.

IBM Engineer Subha Kiran Patnaikuni and Utility Architect Sarbajit Okay. Rakshit are named as co-inventors on the patent. Rakshit boasts practically 20 years of expertise on the firm. He beforehand helped invent a 4D printing drug supply technique and a hologram 3D printing patent revealed in 2019.

Patnaikuni focuses on digital actuality (VR), synthetic intelligence (AI), the web of issues (IoT), robotics, and sensor-driven applied sciences. His earlier patents embrace a digital twin system to enhance evacuation procedures and a robotic safety barrier that employs machine studying (ML) and IoT.

New IBM patent for VR-designed 3D printed buildings

Titled “Developing digital actuality designed buildings,” the patent states that 3D development printing lowers prices, reduces constructing waste, shortens development time, and improves design freedom in comparison with conventional strategies.

The patent additionally emphasizes that, whether or not 3D printed or historically constructed, location and environmental components are important to long-term satisfaction. If these situations are neglected in the course of the design course of, buildings can face expensive and impractical post-construction modifications. IBM’s technique seeks to scale back these dangers by guaranteeing buildings meet all crucial requirements and consumer expectations earlier than development begins.

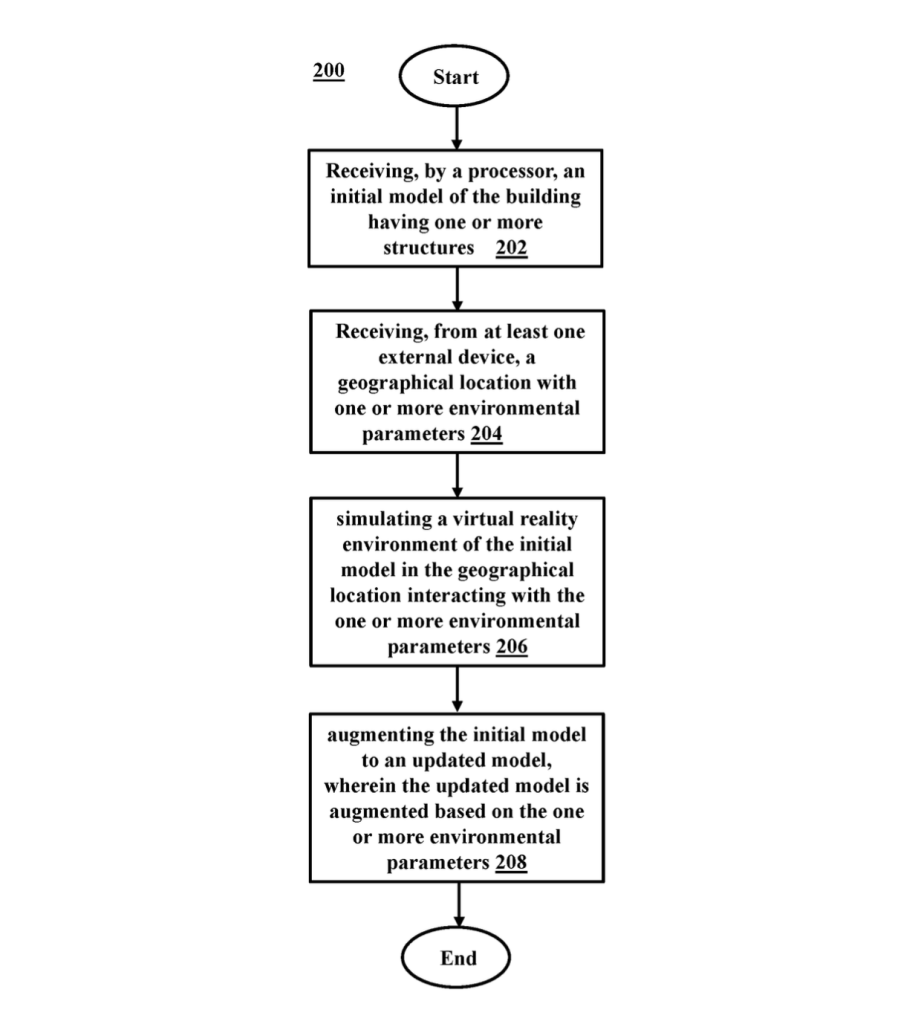

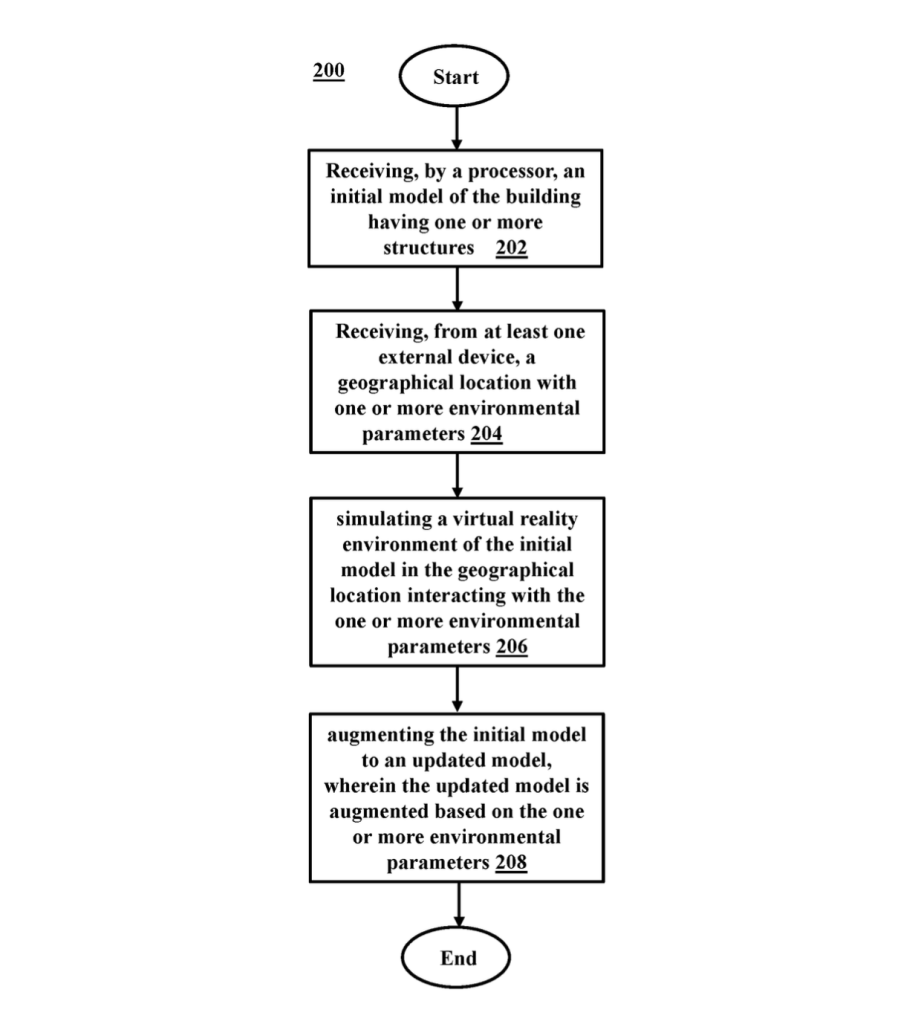

IBM’s course of begins when a 2D or 3D digital blueprint of the proposed constructing is uploaded to the pc program. This file can embrace widespread constructing design options comparable to wall placements, window sizes, room layouts, passages, arches, and development supplies.

Subsequent, IBM’s system gathers environmental knowledge particular to the proposed constructing web site. In keeping with the patent, this info will be sourced from climate satellites, sensors, IoT units, and different environmental monitoring techniques. These inputs present this system with detailed insights into noise ranges, climate situations, airflow, daylight patterns, and potential visible obstructions. The system may also simulate climate situations specified by the consumer.

This knowledge is used to generate a 3D digital reconstruction of the constructing, which is built-in into an correct digital mannequin of the chosen location. Utilizing a VR machine, designers can stroll by the construction and observe how environmental components have an effect on inside situations.

If customers establish points comparable to poor lighting or extreme noise from a close-by prepare monitor, they will request immediate design adjustments, like including insulated home windows or thickening partitions. The system routinely applies these modifications, permitting architects to rapidly assess their impression. It additionally generates dwell suggestions and presents automated design options primarily based on user-defined parameters. As soon as finalized, the design will be exported and despatched on to a 3D printer for development.

Is 3D printing the way forward for development?

IBM just isn’t alone in recognizing the potential of 3D printing for development. Quite a few firms and analysis establishments are increasing their 3D development printing initiatives, drawn by the know-how’s potential for sustainable, inexpensive, and time-efficient tasks.

Earlier this yr, Alquist 3D accomplished a 5,000-square-foot growth of the Owens Cross Roads Walmart Supercenter in Alabama. The Colorado-based development agency used two 3D printers to manufacture 16-foot-high partitions in simply 75 hours over seven days. This marked the quickest timeline Alquist has achieved for a mission of this scale. The development 3D printing mission was reportedly delivered at a fraction of the price of conventional strategies.

Elsewhere, Kentucky-based Somerset Group School (SCC) lately revealed the state’s first 3D printed concrete house. Referred to as Floodbuster 1, the construction was developed utilizing finite factor evaluation and AI to bolster stress-critical sections. These enhancements are designed to face up to EF4 tornadoes and high-velocity flooding. In contrast to most 3D-printed buildings, which regularly function curved partitions, Floodbuster 1 adopts an oblong structure that prioritizes geometric stability and load-bearing effectivity.

In keeping with a white paper authored by Eric Wooldridge and Eldon Whitis of SCC’s Additive Manufacturing Heart, American wood-framed houses typically deteriorate inside 50 to 60 years. Titled Concrete Additive Manufacturing: A Response to America’s Housing Disaster, the examine additionally means that inexpensive housing shortages value the U.S. financial system over $2 trillion yearly. SCC’s 3D-printed constructing goals to exhibit how various development strategies can scale back long-term structural vulnerability whereas enhancing sturdiness and cost-efficiency.

Who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the newest 3D printing information.

You can even comply with us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals the IBM brand. Picture by way of IBM.