That includes PFC and flyback topology, 90% effectivity, and built-in EMI and surge safety, the compact resolution provides strong thermal efficiency and design flexibility with complete documentation and PCB structure help.

Design engineers engaged on LED lighting programs for industrial and industrial environments usually face increased energy necessities than residential setups. Industrial lighting programs demand not solely strong energy supply but additionally dependable thermal administration on account of prolonged working hours and elevated ambient temperatures. This reference design by Toshiba outlines a compact, high-efficiency 100W energy provide meant for such functions. It provides engineers a sensible blueprint that balances electrical efficiency, thermal dissipation, and EMI compliance—key issues in skilled lighting infrastructure.

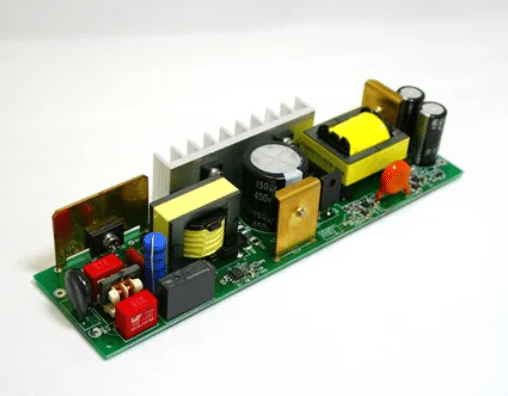

Not like residential lighting, the place energy provides are sometimes miniaturized and embedded inside the lamp enclosure, industrial programs sometimes permit for standalone energy provide models. This eases area constraints and allows using warmth sinks for thermal administration. To streamline warmth dissipation, this design makes use of a through-hole insulated bundle that allows direct warmth sink mounting without having extra insulating sheets, simplifying meeting and bettering reliability.

The facility provide contains two main phases: a Energy Issue Correction (PFC) circuit adopted by a flyback converter. The PFC boosts the enter AC voltage to a steady DC stage of roughly 390 V. The next flyback stage regulates this right down to a relentless output of DC 110 V at 1.04 A, making certain the lighting system receives a steady, flicker-free present supply. The selection of MOSFETs in each the PFC and flyback circuits is predicated on effectivity and thermal efficiency underneath high-voltage operation.

To boost system safety and EMI efficiency, a number of supporting elements are built-in. A ceramic varistor (RV1) protects towards surge voltages, reminiscent of these attributable to close by lightning strikes. X capacitors (Cx, C4, C8) and a standard mode choke (L2) assist suppress each common-mode and differential-mode noise, making certain electromagnetic compatibility. Discharge resistors (R146–R149) are employed throughout capacitors to satisfy security discharge requirements. Designers are inspired to regulate these elements primarily based on the PCB structure and enclosure to optimize EMI suppression.

Rectification is dealt with by a bridge diode (D4), chosen to tolerate the anticipated inrush currents and peak voltages within the working vary. With a excessive conversion effectivity of 90% at 230 V enter and full load, the design helps power financial savings and lowered thermal buildup. The facility provide’s compact type issue—measuring simply 180 mm × 57 mm × 40 mm—makes it appropriate for a variety of business lighting functions.

This reference design offers an entire resolution for engineers, together with steerage on energy system choice (MOSFETs and photocouplers), noise suppression methods, and warmth dissipation strategies—enabling faster growth cycles and enhanced reliability in high-power LED lighting programs.

Toshiba has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) structure, and extra. The corporate’s web site has extra information in regards to the reference design. To learn extra about this reference design, click on right here.