At ETH Zurich, a public analysis college, an interdisciplinary staff led by Professor Mark Tibbitt has developed a 3D printable hydrogel infused with cyanobacteria—photosynthetic microorganisms that take in carbon dioxide from the environment and convert it into each natural biomass and steady, carbonate-based minerals. This innovation goals to scale back the carbon footprint of buildings and infrastructure by passively sequestering CO₂ over time.

“We see our dwelling materials as a low-energy and environmentally pleasant method that may bind CO₂ from the environment and complement current chemical processes for carbon sequestration,” stated Mark Tibbitt, Professor of Macromolecular Engineering at ETH Zurich.

How It Works and Why It Issues

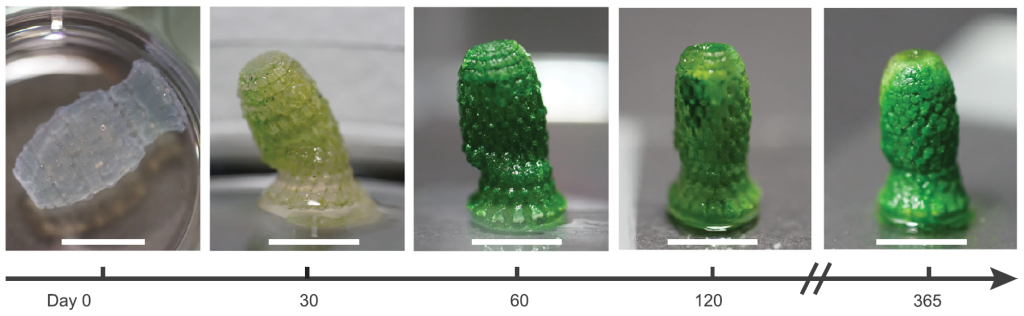

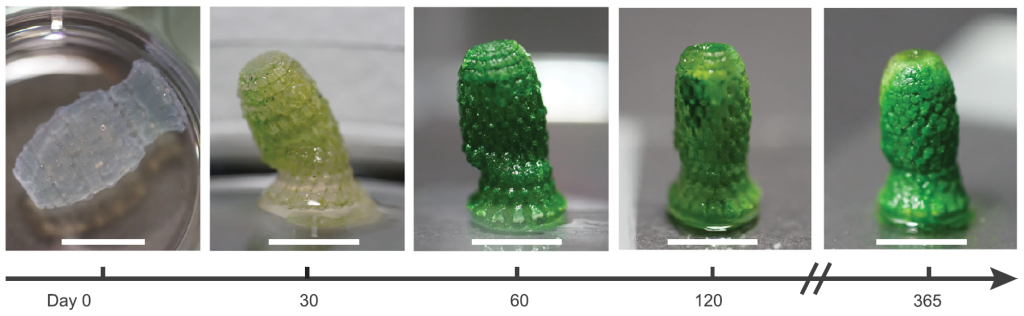

As reported in Nature Communications, the fabric grows and hardens over time whereas repeatedly capturing CO₂, relying solely on mild and a nutrient-rich synthetic seawater answer. What distinguishes it’s its twin carbon sequestration technique, enabling it to soak up extra CO₂ than it shops via natural development alone.

“It’s because the fabric can retailer carbon not solely in biomass, but in addition within the type of minerals – a particular property of those cyanobacteria,” reveals Tibbitt.

The dwelling cells are embedded inside a hydrogel—an aqueous community manufactured from cross-linked polymers with a excessive water content material. The staff chosen the polymer construction to facilitate the transport of sunshine, carbon dioxide, water, and vitamins all through the fabric, whereas guaranteeing the cyanobacteria stay evenly distributed and contained inside it.

To maximise the longevity and effectivity of the cyanobacteria, the researchers optimized the geometry of the constructions utilizing 3D printing strategies. This design enhances floor space, improves mild penetration, and promotes nutrient circulation inside the materials.

Laboratory experiments demonstrated that the fabric steadily captures CO₂ for as much as 400 days, primarily storing it as minerals—roughly 26 milligrams of CO₂ per gram of the fabric. This efficiency exceeds many organic strategies and rivals the chemical mineralization present in recycled concrete, which shops round 7 milligrams of CO₂ per gram.

Future Purposes and Outlook

The researchers emphasize that their dwelling materials represents an energy-efficient and environmentally sustainable method to capturing atmospheric CO₂, with potential to enrich current chemical sequestration strategies.

“Sooner or later, we need to examine how the fabric can be utilized as a coating for constructing façades to bind CO2 all through the whole life cycle of a constructing,” says Tibbitt.

Advancing Sustainable Building Via 3D Printing

3D printing is more and more being utilized to scale back the environmental affect of conventional building strategies. According to this pattern, UK power firm Nationwide Grid has launched a UK-first trial to fabricate, set up, and take a look at 3D printed concrete foundations for substations, in collaboration with Finnish concrete 3D printing specialist Hyperion Robotics and the College of Sheffield within the UK. The venture goals to evaluate whether or not this building methodology can scale back carbon emissions, decrease materials waste, and decrease total community infrastructure prices.

Equally, the College of Virginia (UVA) has made strides in enhancing the sustainability of 3D printed concrete. Researchers there developed a cementitious composite by incorporating graphene nanoplatelets (GNPs) into limestone-calcined clay (LC2). Remarkably, including simply 0.05% GNPs by weight enhanced the compressive power of the concrete by 23% whereas lowering greenhouse fuel emissions by practically 31% in comparison with conventional cement mixtures. This graphene-enhanced concrete boosts structural efficiency and helps environmental goals by decreasing the carbon footprint of building supplies.

Be part of our Additive Manufacturing Benefit (AMAA) occasion on July tenth, the place AM leaders from Aerospace, House, and Protection come collectively to share mission-critical insights. On-line and free to attend. Safe your spot now.

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to maintain up with the newest 3D printing information.

It’s also possible to comply with us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture reveals Steady tradition over 400 days. Picture by way of ETH Zurich.