A 3D printed security machine has helped save the lifetime of an NTT INDYCAR SERIES driver.

Josef Newgarden was concerned in a high-speed collision with Louis Foster in the course of the latest Bommarito Automotive Group 500 race on the World Large Expertise Raceway in Madison Illinois.

Newgarden, a two-time INDYCAR SERIES champion, collided with Foster on lap 131, sending his No. 2 Chevrolet airborne. The Group Penske driver landed the other way up, earlier than skidding alongside the tarmac in a bathe of sparks.

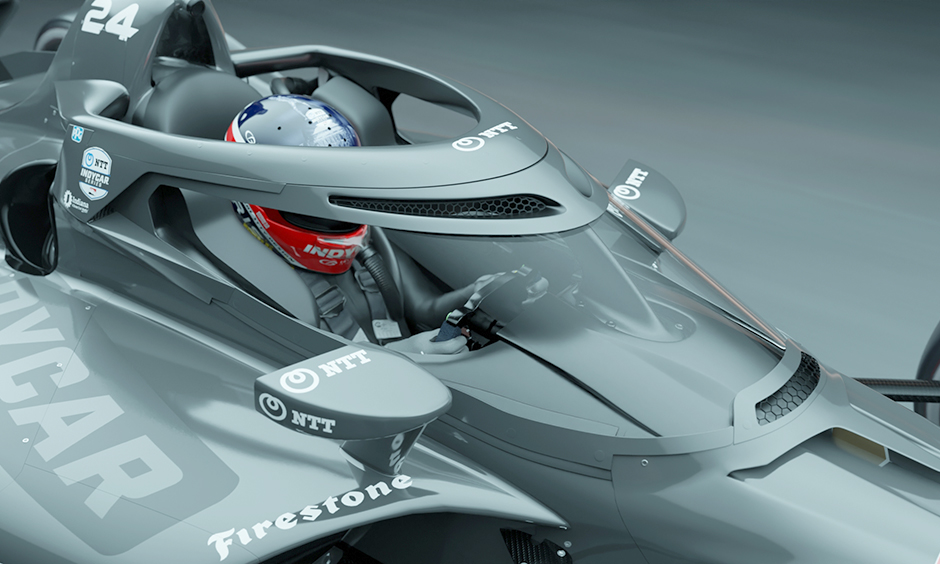

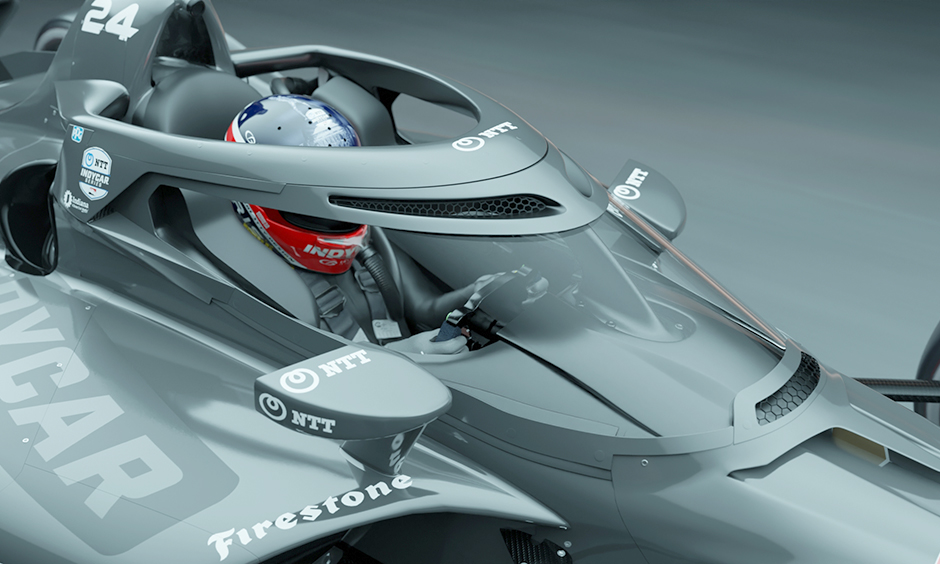

After being righted by the American Medical Response Security Group (AMR), Newgarden was in a position to climb out of the automobile, escaping critical harm. The brunt of the pressure was absorbed by his Aeroscreen, a 3D printed cockpit security machine that was first launched in 2020 and up to date with a extra light-weight design in 2024.

Foster, a Rookie driving for Rahal Letterman Lanigan Racing, spun out with main injury to his Honda-powered Dallara chassis. He additionally walked away largely unscathed after his Aeroscreen deflected a hail of particles.

The machine is a compulsory function on all NTT INDYCAR SERIES vehicles for street and avenue course races. It contains a 3D printed titanium body, engineered by Pink Bull Superior Applied sciences (RBAT) and manufactured by the Austrian mechanical methods firm Pankl.

This body is paired with a laminated polycarbonate ballistic windscreen, developed by plane windshield specialist PPG Industries. Collectively, they type a protecting barrier related in operate to the Halo crash-protection system utilized in System 1 since 2018.

3D printed Aeroscreen enhances IndyCar security

Previous to its 2020 debut, a number of manufacturing methods have been explored for Aeroscreen manufacturing.

The primary design was reportedly made utilizing titanium casting. Nevertheless, prolonged manufacturing lead occasions made it unable to fulfill the tight deadline forward of the 2020 INDYCAR season opener. Consequently, Pankl was chosen to manufacture the body utilizing its EOS M400-4 laser powder mattress fusion (LPBF) 3D printer.

The unique Aeroscreen (Model 1.0) featured a body constructed from 5 3D printed sections welded collectively. In pre-race testing, it withstood forces equal to 34,000 kilos, whereas the ballistic windscreen was examined to endure the influence of a 17.3-pound object touring at 220 mph. The machine made its on-track debut throughout testing at Indianapolis Motor Speedway in October 2019 and was formally launched in competitors in February 2020.

Final 12 months, INDYCAR launched Model 2.0, a lighter display designed to reinforce efficiency and luxury. It consists of built-in air vents to enhance cockpit cooling, together with a front-facing rubber 3D printed to assist forestall hand accidents throughout a crash.

The up to date design first hit the monitor in the course of the 2024 Acura Grand Prix in Lengthy Seashore. Its weight was trimmed from 18.9 lbs on Model 1.0 to 14.5 kilos, whereas retaining the identical energy as the unique. That is because of the brand new, topologically optimized 3D printed titanium body.

Mixed with the ballistic windscreen, the up to date Aeroscreen affords a complete weight discount of 11.1 kilos, decreasing downforce by roughly 35 lbs.

Enhanced cooling performs a vital function in boosting driver efficiency, based on Tino Belli, Director of Aerodynamic Growth for the NTT INDYCAR SERIES. She famous in a press launch that drivers persistently emphasised the necessity for higher airflow, as their physique temperatures usually exceed 100°F throughout races. Racing groups can even set up an optionally available filter to assist hold mud out of the cockpit.

Additive manufacturing accelerates motorsport

3D printing isn’t new in motorsport. Racing groups have lengthy leveraged additive manufacturing to supply an edge on the monitor. For instance, the Oracle Pink Bull Racing F1 Group is a eager adopter of superior applied sciences, together with 3D printing.

In an interview with 3D Printing Business, Ian Handscombe, Head of High quality Engineering at Pink Bull Racing, claimed: “I don’t assume we are going to proceed to be on monitor until we embrace [3D printing].”

Technical partnerships with corporations play a key function in supporting additive manufacturing at Pink Bull Racing. A lot so, forward of the 2025 F1 season, Pink Bull prolonged its long-term collaboration with manufacturing expertise firm Hexagon. This builds on an 18-year-long relationship with Hexago because the crew’s unique metrology accomplice.

The Swedish agency provides Pink Bull with 3D scanners and digitalization capabilities. This expertise permits the F1 stalwart to make over 20,000 automobile design modifications every season. Based on Hexagon, metrology expertise has helped lower faults by over 50% over the previous two years.

Elsewhere, BWT Alpine F1 crew leverages 3D Methods’ SLA and SLS 3D printers to assist System 1 wind tunnel testing. The racing crew reportedly 3D prints 25,000 components yearly to scale back analysis and improvement time and enhance on-track efficiency.

Equally, the McLaren F1 racing crew has an extended partnership with 3D printer OEM Stratasys. Courting again to 2017, this collaboration has seen McLaren leverage 5 Stratasys Neo 800 to assist aerodynamic wind tunnel components. Elsewhere on the grid, Alfa Romeo Racing made intensive use of Additive Industries’ MetalFAB1 3D printer in the course of the 2021 season. The crew 3D printed light-weight racing automobile elements, which price 90% lower than these produced utilizing conventional strategies.

Who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business publication to maintain up with the most recent 3D printing information.

You can even comply with us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits Josef Newgarden’s INDYCAR crash. Picture by way of NTT INDYCAR SERIES.