Throughout a current tour of Materialise’s world headquarters in Leuven, I used to be given a uncommon glimpse into the corporate’s aerospace 3D printing operations.

The Belgian software program agency runs a contract manufacturing service that provides totally licensed elements for the aerospace and aviation industries. Leveraging a fleet of FDM and SLS machines, the corporate produces a variety of flight-ready polymer elements. These seem in numerous industrial plane, together with Airbus’s airliners and the Dornier 328 turboprop.

I sat down with Jan Van Espen, Digital Intelligence Supervisor, and Erik de Zeeuw, Market Supervisor of Licensed Manufacturing, to be taught extra about Materialise’s aerospace 3D printing capabilities.

They highlighted the corporate’s distinctive place as a licensed provider of flight-ready elements for Airbus, backed by AIPI 03-02-029 accreditation for 3D printing with Ultem 9085CG. The 3D printing software program developer additionally holds EN 9100 aerospace certification for each its polymer 3D printing and Bremen-based steel additive manufacturing providers.

Additive Manufacturing Benefit: Aerospace, House and Protection returns on July tenth. Reserve your free ticket now.

Up to now, Materialise has 3D printed upwards of 500,000 aerospace elements, industrializing over 4,000 completely different licensed flying elements. Each aerospace specialists acknowledged steel AM’s essential function in “superhero purposes,” like jet engines and gearboxes. Nevertheless, Materialise primarily delivers the “unsung heroes” for Upkeep, Restore, and Overhaul (MRO) that maintain airliner fleets operational, like cabin elements and discontinued substitute elements.

De Zeeuw described additive manufacturing as “one other device in your toolbox,” highlighting vital benefits in time, value, and gasoline effectivity. It allows Materialise prospects to entry new polymer 3D printed elements in simply days or even weeks, in comparison with the months required by conventional strategies. “Clients are sometimes stunned by how shortly we will industrialize elements,” De Zeeuw added.

Aerospace 3D printing at Materialise HQ

Materialise’s aerospace manufacturing focuses totally on polymer 3D printing for low-critical elements. At its Leuven facility, the corporate splits its output roughly evenly between FDM and SLS applied sciences, relying on half geometry and manufacturing quantity necessities.

Most of this work helps plane cabin elements for MRO actions. These purposes sometimes contain high-mix, low-volume manufacturing runs to assist reconfigurations or format adjustments in plane interiors. As an example, Materialise continuously manufactures ducting parts and small structural brackets that require minimal post-processing.

The Belgian firm started working with Airbus in 2015, initially supplying FDM-printed elements for the A350 XWB after acquiring EN9100 and EASA 21G certification. The partnership shortly advanced right into a key factor of Airbus’s cabin improve technique. By 2018, Materialise was deploying its in-house FDM methods to fabricate customized spacer panels. These have been reportedly the primary passenger-visible, 3D printed elements to look in industrial plane cabins.

The elements, which fill gaps between overhead storage bins, achieved full bionic design certification and have been 15% lighter than conventionally produced alternate options. By 2021, Materialise was 3D printing 100 completely different sorts of flight-ready elements for the A350, with some 26,000 models put in throughout the worldwide fleet.

2021 additionally noticed Materialise develop into certified to 3D print SLS flight-ready elements for Airbus. The settlement noticed Materialise fabricate elements utilizing EOS’ flame-retardant polyamide (PA) powder, PA 2241 FR. This transfer marked Airbus’ preliminary foray into SLS additive manufacturing. Materialise and EOS turned the primary corporations accredited to 3D print elements below Airbus Course of Specification AIPS 03-07-022. This specification units the necessities for fabricating flight-ready elements utilizing laser sintering.

Elsewhere, Materialise beforehand partnered with 328 Assist Providers (now Deutsche Plane GmbH) to supply plastic spare elements for the Dornier 328 plane. These spares are lighter, cheaper, and quicker to make than conventional alternate options, demonstrating the worth of additive manufacturing for producing high-quality, on-demand aftermarket elements.

De Zeeuw referred to as these the “unsung heroes” of aerospace 3D printing. Whereas vital, they’re much less flashy than “superhero purposes,” like 3D printed jet engine elements, which Materialise doesn’t serve straight. For Van Espen, the engine and gearbox markets are “leaping on steel AM essentially the most.” That is due to the load discount, design freedom, and gasoline effectivity benefits of 3D printing.

Certainly, some of the well-known aerospace 3D printing examples is GE’s gasoline nozzle suggestions, that are 25% lighter and 5 instances extra sturdy than conventionally manufactured variations. Every GE Aerospace LEAP engine comprises 19 of those 3D printed nozzles, boosting gasoline effectivity by 15% in comparison with CFM56 engines. Whereas Materialise has not but entered this market, its on-demand, MRO 3D printing service performs an important function in protecting industrial airliners flight-ready.

Materialise’s additive manufacturing benefit for aerospace

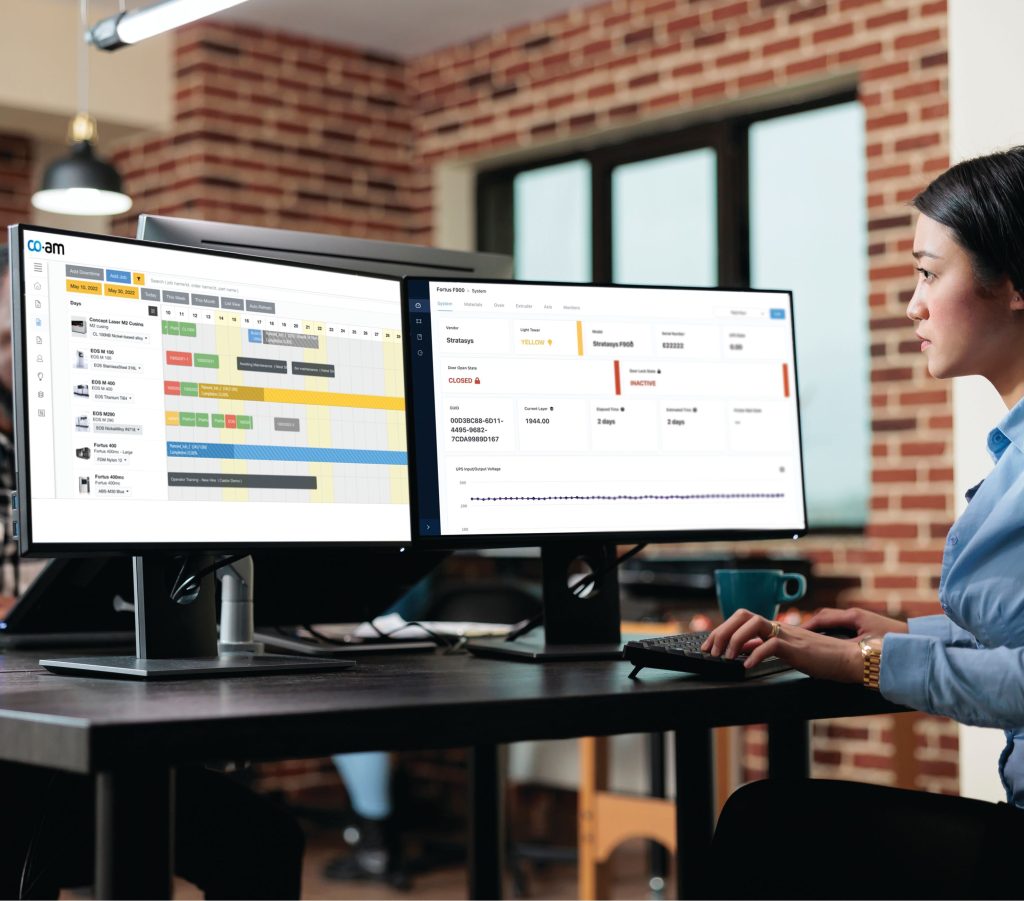

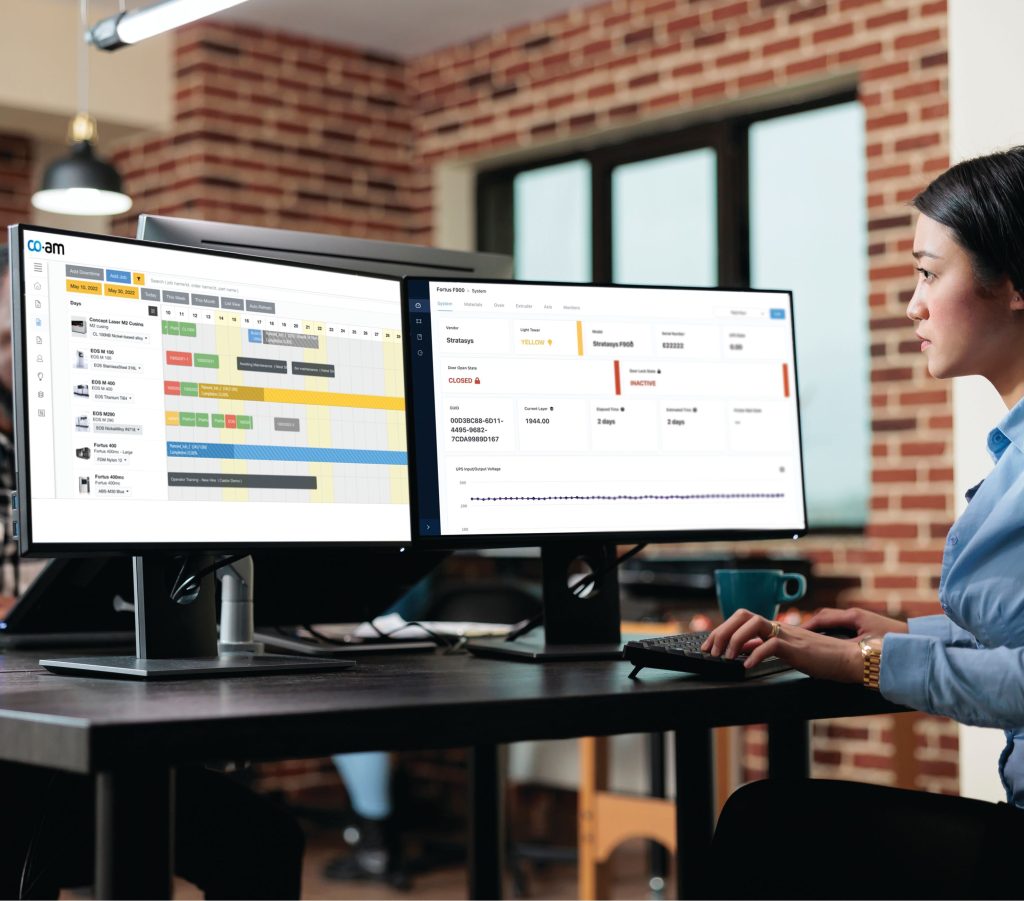

Throughout our dialog, De Zeeuw and Van Espen defined that Materialise expertise has develop into a essential cog within the aerospace additive manufacturing ecosystem. Along with its contract manufacturing service, the corporate provides CO-AM, an industrial 3D printing software program that helps the manufacturing of high-quality, repeatable elements.

In accordance with De Zeeuw, the platform allows aerospace corporations to scale their manufacturing capabilities greater than different enterprise methods, which regularly restrict progress. “They lack methods to assist that scaling, and it can’t be finished with conventional ERP or MES methods,” he stated.

Van Espen noticed that many aerospace producers “lack confidence” in additive manufacturing’s means to fulfill stringent trade requirements persistently. Materialise seeks to deal with these considerations with CO-AM, which is designed to “improve the boldness in 3D printing for essential elements.”

Materialise CO-AM is an open, cloud-based platform that connects a spread of software program instruments for planning, managing, and optimizing manufacturing workflows. By integrating instruments from each Materialise and third-party distributors, customers can streamline essential operations and scale additive manufacturing extra effectively.

Amongst its capabilities, CO-AM provides computerized 3D printed assist era, end-to-end traceability, high quality management, and safe information administration. The platform helps real-time monitoring of construct processes, centralizes materials and machine information, and allows digital certification workflows.

These capabilities assist producers meet rigorous regulatory requirements whereas enhancing manufacturing effectivity and repeatability. “For medical and aerospace mixed, a couple of million serial steel elements have already been printed through our spine methods,” Van Espen revealed.

How does Materialise’s software program differentiate from the competitors? For Van Espen, the benefit lies in the truth that the corporate validates its software program in-house. Not like corporations that develop software program in isolation, Materialise develops, exams, and deploys its platforms inside its licensed manufacturing environments. This shut integration, Van Espen claimed, allows the corporate to anticipate challenges 5 to 10 years forward of its rivals.

Materialise’s twin function as each a service bureau and software program supplier grounds its improvement cycles in sensible, real-world calls for. By serving high-volume shoppers within the aerospace and medical sectors, the corporate focuses past short-term developments. “Once they speak brief time period, they imply a minimum of three years,” Van Espen famous.

The Leuven-based agency develops long-term roadmaps with shoppers to make sure shut alignment with product expectations and outcomes. It additionally fosters shut relationships with 3D printer producers, making certain the software program is appropriate with most industrial steel and polymer 3D printers in the marketplace. “We connect with nearly each skilled machine,” defined De Zeeuw. He added that few rivals can match the size, maturity, or testing infrastructure of Materialise, which boasts 35 years of 3D printing expertise.

Certifying flight: course of management in aerospace 3D printing

In extremely regulated sectors akin to aerospace, traceability and high quality assurance are important. Constant materials properties and manufacturing high quality underpin each security and compliance. For Materialise’s aerospace specialists, delivering licensed, repeatable outcomes stays one among additive manufacturing’s most formidable challenges.

“If you’re printing, you’re making your properties when you’re printing,” defined De Zeeuw. “Should you begin with unhealthy materials, you gained’t be capable to right it.” Even when beginning with high-quality feedstock, outcomes can range between 3D printers except processes are tightly aligned. “Course of management is vital,” he added. “It’s worthwhile to have proof of your output, as a result of the authorities acknowledge this threat.”

Materialise overcomes these challenges by leveraging statistical information recorded all through all manufacturing runs. This data is leveraged in course of management instruments, growing confidence that every 3D printed half matches the meant property necessities.

The necessity for consistency extends far past the construct. Van Espen underscored that high quality documentation and information should typically be preserved. For shoppers like Airbus, which means constructing solely separate high quality processes, backed by full traceability via CO-AM software program.

As delicate manufacturing information shifts to digital platforms, cybersecurity and mental property safety considerations are mounting throughout the aerospace trade. Materialise protects towards these threats with its Digital Rights Administration (DRM) system. This ensures {that a} buyer’s information can’t be tampered with, misused, or overproduced.

“If Airbus says, ‘we would like you to print 100 elements,’ then we will print 100 elements, however no more,” Van Espen defined. The system locks down all print parameters, making piracy, file corruption, and even inadvertent adjustments just about not possible. Materialise’s software program safety credentials are backed by ISO 27000 certification. In accordance with De Zeeuw, this confirms that the corporate’s software program builders “work in a cyber-secure approach, and that their merchandise are fairly safe.”

For aerospace shoppers conducting distributed manufacturing with the CO-AM platform, Materialise turns to its Identify3D model. Acquired in September 2022, Identify3D supplies encryption, entry management, and traceability for digital half information, serving to forestall tampering and counterfeiting. The software program permits designers to lock information to particular customers, machines, or supplies, making certain manufacturing aligns with the unique specs.

The way forward for 3D printing for aerospace

As aerospace 3D printing matures at Materialise, the subsequent 18 months will prioritize scaling manufacturing, particularly for steel elements. “We’ve simply established our EN 9100 certification,” defined De Zeeuw. “So now it’s time to land these first steel purposes.”

For Materialise, success goes past technical functionality; it means licensed elements flying aboard actual plane. The corporate can be increasing its polymer manufacturing capability, aiming to unlock new aerospace purposes for established supplies akin to ULTEM and PA. On the similar time, it’s exploring next-generation, high-performance alternate options. Trying forward, De Zeeuw pointed to promising DLP resins that mix photo- and thermally curable properties. These dual-curable supplies supply enhanced resistance to UV, warmth, and doubtlessly even hearth, broadening the scope for aerospace purposes.

Van Espen expects a pivotal shift within the coming months, as extra 3D printer OEMs open their methods to exterior software program platforms akin to Materialise’s CO-AM. “There’s recognition now that they should combine higher with scalable software program,” he famous. This push for 3D printer interoperability will probably be important as additive manufacturing scales from prototyping to industrial-scale, repeatable manufacturing.

Over the previous 35 years, Materialise has carved out a essential function within the aerospace provide chain. As each a producer and software program developer, the corporate occupies a uncommon place in an trade the place traceability, consistency, and long-term reliability carry extra weight than hype. Its “unsung heroes” play an important function. They minimize prices, velocity up lead instances, and streamline plane upkeep, serving to additive manufacturing acquire much-needed altitude within the aerospace sector.

Be part of our Additive Manufacturing Benefit (AMAA) occasion on July tenth, the place AM leaders from Aerospace, House, and Protection come collectively to share mission-critical insights. On-line and free to attend. Safe your spot now.

Who gained the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business publication to maintain up with the newest 3D printing information.

You may as well comply with us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits Materialise Leuven HQ. Picture by Michael Petch.

![[INTERVIEW] 3D Printing Aerospace’s “Unsung Hero” Functions at Materialise HQ [INTERVIEW] 3D Printing Aerospace’s “Unsung Hero” Functions at Materialise HQ](https://i3.wp.com/3dprintingindustry.com/wp-content/uploads/2017/04/Materialise-Leuven-HQ.-Photo-by-Michael-Petch..jpg?w=696&resize=696,0&ssl=1)