A current social media publish caught my eye, one thing that may very well be described because the antithesis of LinkedIn. As an alternative of the everyday self-congratulatory product launch or inflated efficiency claims, it was a blunt video clip of a combustion chamber tearing aside beneath strain.

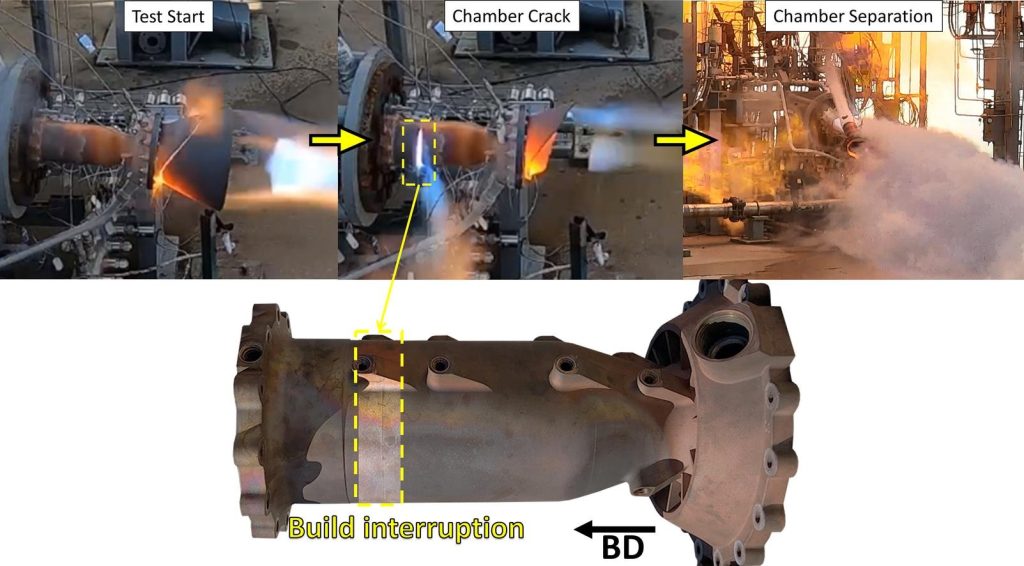

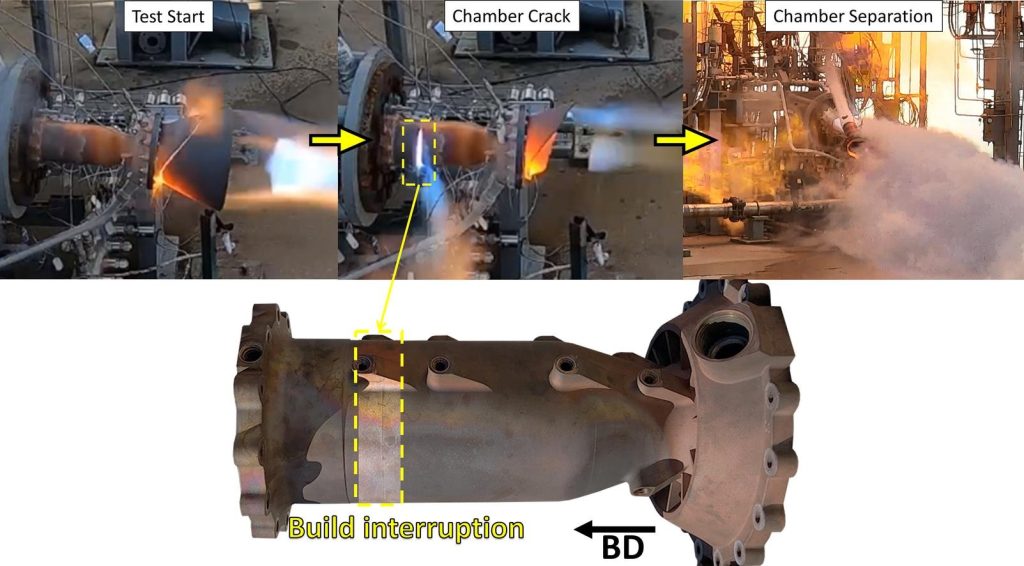

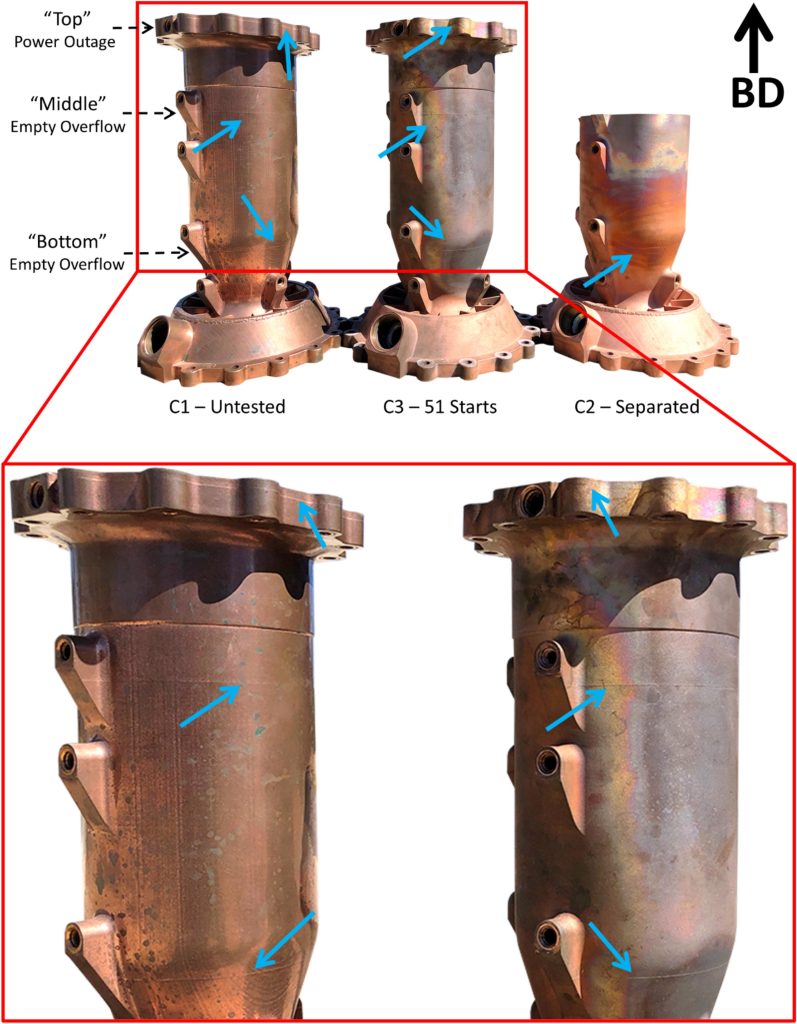

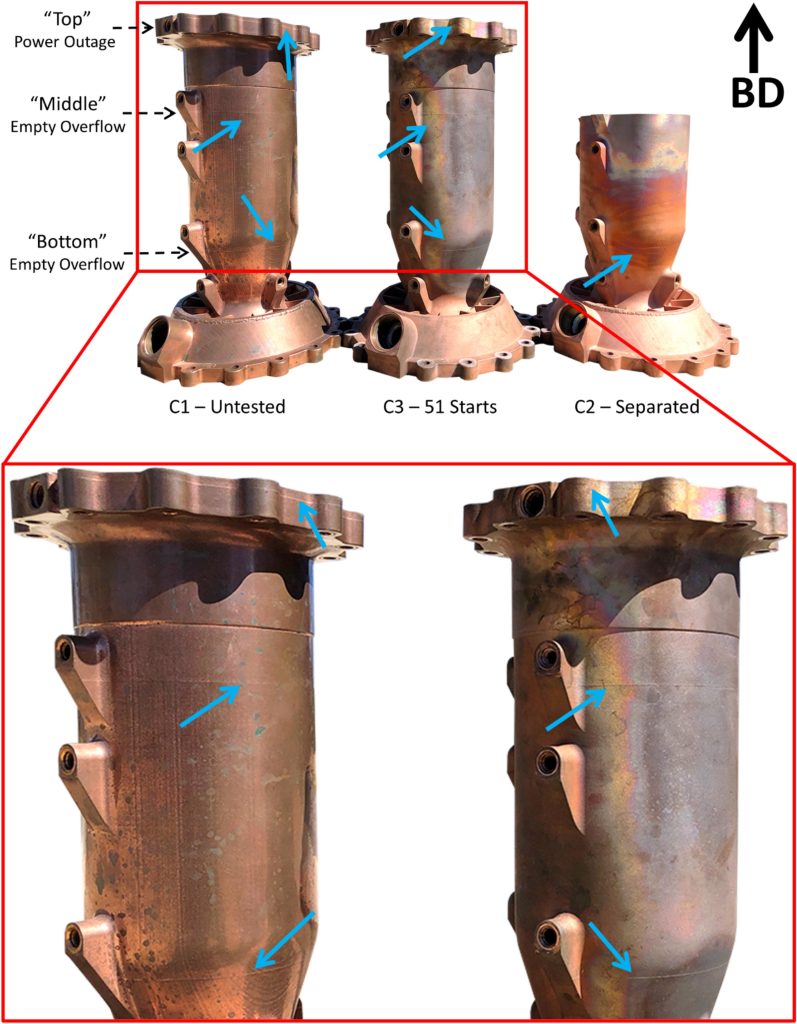

Throughout hot-fire testing, an additively manufactured GRCop-42 combustion chamber failed and with it, provided a robust failure evaluation case research within the unforgiving physics of propulsion {hardware}. The incident demonstrates how a pause in construct continuity can cascade into structural defects like lack of fusion and porosity, in the end compromising mission-critical elements.

At NASA’s Marshall Area Flight Middle, Gabriel Demeneghi leads a staff of fabric scientists working with superior manufacturing and space-grade reliability. “My staff could be very numerous,” he says. “Now we have folks doing microgravity experiments, in-space welding, alloy improvement, and full characterization: from optical microscopy to mechanical testing.”

Demeneghi’s personal focus spans two fronts: supporting high-level PhDs in eradicating technical roadblocks and executing his personal initiatives, which emphasize mechanical characterization, fatigue testing, and failure evaluation. “We’re doing fatigue bending for supplies that can’t maintain shear forces, like lunar regolith or nuclear gasoline,” he explains.

Be part of AM area specialists on July tenth at Additive Manufacturing Benefit: Aerospace, Area & Protection. Areas are restricted for this free on-line occasion. Register now.

Public Information, Personal Capabilities

Not like many industrial laboratories, NASA’s work doesn’t keep behind closed doorways. One core mission is to make materials efficiency information publicly out there, reducing obstacles for smaller aerospace firms unable to fund exhaustive testing. “Giant firms can spend hundreds of thousands on mechanical exams,” says Demeneghi, “however if you happen to get a smaller firm, they don’t have the identical functionality. So NASA takes on that burden and makes the information public.”

The purpose is to construct accessible databases of take a look at outcomes, from tensile power and porosity to thermal biking, enabling downstream customers to make knowledgeable choices about alloys, remedies, and design margins.

Failure evaluation at NASA is as a lot forensic science as engineering.

For instance, contemplate the United Launch Alliance tank failure. The size of the wreckage, multi-meter fragments, means the method typically begins with visible inspection and macro pictures earlier than transferring into higher-resolution methods like scanning electron microscopy.

As additive manufacturing applied sciences proliferate, Demeneghi’s staff is tasked with figuring out their sensible limits. “Everybody’s making an attempt to promote the subsequent smartest thing since sliced bread,” he says. “However we have now to seek out the constraints.”

A lot of that work facilities on floor topography and microstructural anomalies. AM-produced components typically include options that function fatigue crack initiation websites. “We take a look at every thing from as-printed components to post-processing, together with warmth remedies like HIP to scale back porosity,” he explains. Information from this course of informs whether or not floor sharpening or machining can mitigate defect dangers with out compromising the element.

Microgravity Metallurgy, and the Fringe of AM Qualification

NASA’s materials decisions replicate the brutal thermal and mechanical regimes of rocketry. GRCop-42, a copper-based alloy designed to retain power at excessive temperatures, is steadily utilized in combustion chambers. “On one aspect of a one-millimetre wall you have got cryogenic temperatures; on the opposite, combustion at 400-700°C,” Demeneghi notes. GRCop retains 70–80% of pure copper’s conductivity whereas providing superior mechanical efficiency.

The place increased structural power is required, alloys like Inconel or NASA HR-1 come into play. For nozzles and environments demanding excessive warmth resistance, C-103 (a refractory niobium alloy) is most well-liked. “It’s not one alloy matches all,” he provides. “It’s all the time about designing for the applying.”

In the case of fatigue failure, NASA’s technique is application-specific. “For combustion chambers, we’re involved with thermal mechanical fatigue, particularly at low cycle pressure charges between 0.5% and a pair of%,” says Demeneghi. “However for turbine blades, it’s high-cycle fatigue that issues.” Whereas the staff tailors take a look at regimens to anticipated use, they nonetheless carry out a full characterization to make sure broad usability of the dataset.

The connection between supplies and design in space-grade engineering stays tightly coupled. “It’s a chicken-or-egg scenario,” says Demeneghi. One metal alloy proof against hydrogen embrittlement, presumably A286, illustrates the purpose. “It’s not printable,” he explains. To handle this, NASA developed HR-2 (Hydrogen Resistant alloy model two) tailor-made for compatibility with additive processes whereas retaining efficiency beneath hydrogen-rich situations.

GRCop and the Warmth Barrier

The pursuit extends to cost-driven substitutions for high-temperature refractory alloys. Whereas GRCop-42, a copper–chromium–niobium alloy, is more and more deployed in combustion chamber builds, its prices stay a priority. “Niobium is extraordinarily costly,” Demeneghi notes. “However if you happen to want power at excessive temperatures, you want that Cr–Nb ratio. Each have low solubility in copper and excessive affinity to one another, forming a precipitate that reinforces the microstructure.” Copper–chromium alone breaks down beneath elevated situations. “It’s solely efficient to round 500°C. Then it dissolves and loses power,” he says. NASA is actively engaged within the seek for each options and works to engineer new supplies that preserve the required efficiency.

Microstructure Management at Excessive Temperatures and 3D Printing in Area

Refractory AM techniques current contemporary challenges for microstructure stability. Past copper alloys, NASA can be exploring supplies like tungsten–tantalum carbides and ceramics, which require excessive print temperatures to forestall particle agglomeration. “You want a 50% overlap in the course of the construct to maintain particles dispersed,” says Demeneghi. “However you’ll be able to’t do this on the contour layer, which results in clustering.”

The staff has but to achieve the elusive purpose of full management over microstructure evolution in additive builds. “Additive was speculated to be absolutely controllable. Some folks confirmed outcomes, however I don’t know in the event that they have been ever replicated.”

NASA’s ongoing analysis consists of direct comparisons between welds made in area and on Earth. Whereas the outcomes usually are not but public, Demeneghi hints at future findings. “We’re how warmth switch and solidification differ with gravity. Microgravity could result in extra homogeneous supplies, however we don’t know but.”

Brief-duration zero-G experiments by way of parabolic flights are restricted to fast-solidifying techniques, like dental amalgam, because of the tight 30-second window. To copy the complete spectrum of area situations (vacuum, radiation, thermal extremes, and so on.) NASA is constructing environmental chambers.

Demeneghi stays cautious: “I don’t assume microgravity is healthier or worse. It’s simply completely different. It’ll require full recharacterization.”

A distinguished development in AM for spaceflight includes combining a number of processes to sidestep scale and backbone constraints. “We are able to do fantastic options with laser powder mattress fusion after which add bulk by way of directed vitality deposition (DED),” says Demeneghi. “Or mix additive with subtractive or casting.” Laser powder mattress retains benefits as a result of finer powders, sometimes half the scale of DED, and tighter floor tolerances. “You get fewer floor discontinuities,” he explains. However pushing this course of to propulsion-scale elements is the place qualification hurdles emerge.

Failure, Restart, and Course of Management

Again to that aforementioned nozzle failure in a chamber, which supplied a dramatic reminder of additive’s sensitivity to manufacturing variables. “There was an interruption in the course of the construct, presumably an influence outage or powder refill, that led to lack of fusion, porosity, possibly oxidized powder,” Demeneghi says. “The restart protocol wasn’t adopted correctly.”

Witness specimens printed beneath managed restart situations confirmed no defects, affirming that it was a procedural oversight, not a basic flaw with laser powder mattress fusion. Requested in regards to the position of thermal simulation in additive manufacturing, Demeneghi signifies that, whereas helpful, simulation alone can not change rigorous testing. The complexity of fabric habits, significantly beneath excessive situations, nonetheless requires empirical information. “You want tight management, however you additionally want verification. Fashions are helpful instruments, however they will’t seize every thing.”

Establishing requirements and producing take a look at coupons stays central to mitigating danger. “With each fabrication, possibly produce witness specimens and take a look at at completely different construct heights,” he suggests. He’s pragmatic concerning the position of simulation in additive manufacturing. “It’s a belief however confirm scenario,” he says. Whereas physics-based fashions assist, they don’t seem to be infallible. “We are able to predict fatigue failure very properly, and nonetheless 90% of failures are as a result of fatigue. So predicting will not be all the time correlated to avoiding it.”

He additionally highlights the tempo mismatch between personal companies and authorities companies. “We can not work on the tempo that they work. Now we have much more purple tape, but additionally folks with 40 years of expertise. It’s a superb partnership. They transfer quick, and we assist with qualification.”

Replicability vs. Repeatability and Subsequent-Gen {Hardware} Wants

In his view, NASA’s best contribution could also be in its measured, test-heavy tradition. Personal launch companies could possibly transfer sooner, however Demeneghi emphasizes the worth of deep supplies information. “We’re all the time concerned. Weekly conferences with SpaceX and Blue Origin. They profit from the expertise we deliver, even when we don’t share their tempo.”

Whereas Demeneghi focuses on characterization relatively than machine improvement, he sees AM’s bottlenecks as mendacity much less in {hardware} and extra in procedural management. Finally, he views AM in propulsion as transferring quick, however solely as quick as its weakest parameter permits. “It is advisable management the method very tightly. Particularly in rocketry. Hundreds are excessive. There’s no room for error.”

Private or skilled opinions expressed on this article are Gabriel Demeneghi’s and don’t, in any approach, characterize the opinion or coverage of NASA.

Be part of AM leaders on July tenth at Additive Manufacturing Benefit: Aerospace, Area & Protection. Areas are restricted for this free on-line occasion. Register now.

Subscribe to the 3D Printing Business publication to maintain up with the most recent 3D printing information. You can even comply with us on LinkedIn.

Featured picture is sequence illustrating how the thrust chamber meeting (TCA) failed throughout testing. Photograph by way of ScienceDirect.