Stanford researchers have taken a serious step towards addressing one of many greatest hurdles in organ bioprinting: constructing real looking vascular networks able to sustaining lab-grown tissue. Their new platform, printed June 12 in Science, accelerates the design of those blood vessel programs and interprets them into 3D printable fashions—bringing the promise of customized, practical organs nearer to actuality.

Overcoming the Vascular Barrier in Organ Bioprinting

Greater than 100,000 folks within the U.S. are presently on organ transplant ready lists, many for years—and a few received’t survive the wait. Even when a donor organ turns into out there, the danger of immune rejection stays excessive. To beat these limitations, regenerative medication researchers are working to manufacture organs like hearts, kidneys, and livers utilizing a affected person’s personal cells.

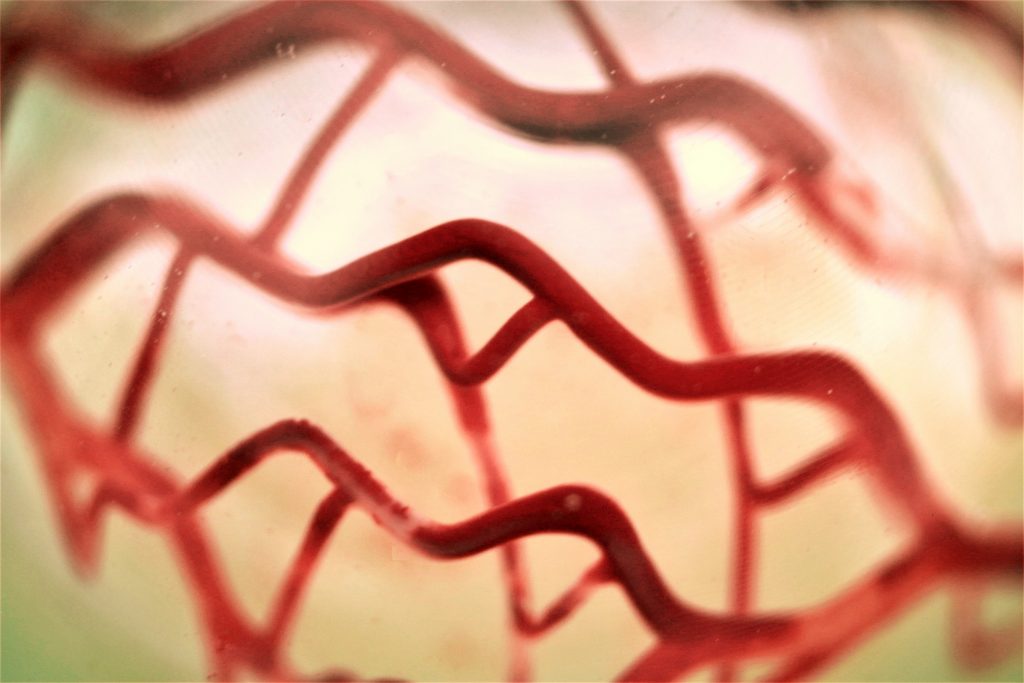

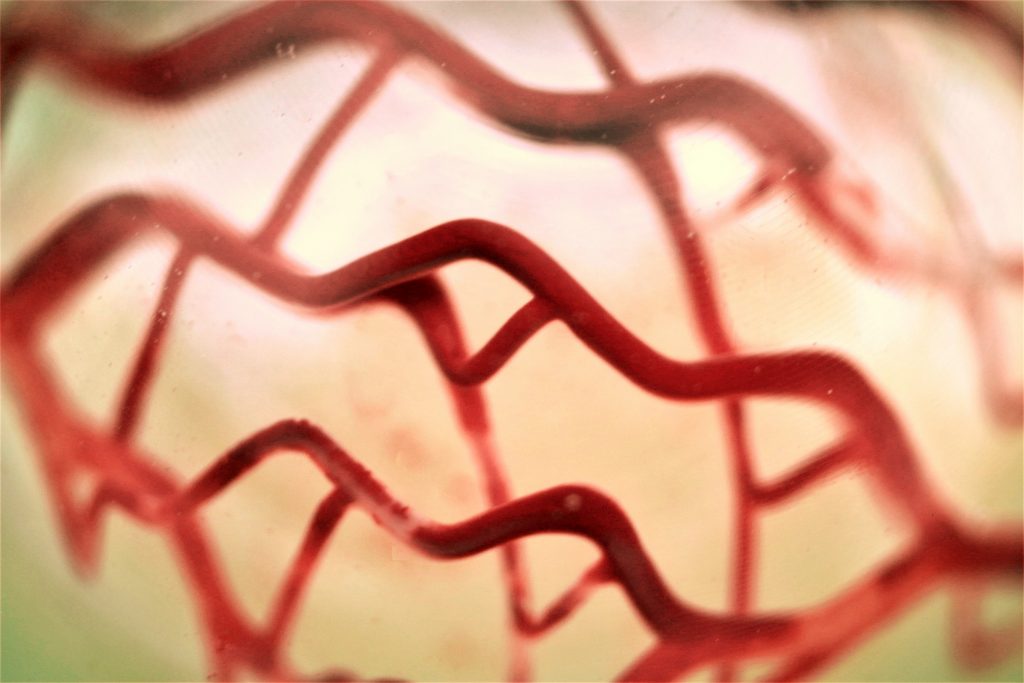

A essential problem on this course of is replicating the physique’s intricate vasculature Blood flows from giant arteries into smaller vessels that ship oxygen and vitamins to cells, which should be very shut to those vessels to outlive—particularly in demanding organs like the guts. Vascular networks differ broadly between organs and people, making it troublesome and time-consuming to create correct fashions. Many researchers depend on standardized buildings that work for small tissues however don’t scale effectively for bigger, advanced organs.

“The flexibility to scale up bioprinted tissues is presently restricted by the power to generate vasculature for them – you possibly can’t scale up these tissues with out offering a blood provide,” stated Alison Marsden, Professor of pediatrics and of bioengineering at Stanford within the Faculties of Engineering and Drugs and co-senior creator on the paper.

Accelerating Reasonable Vascular Community Technology

The Stanford crew developed an algorithm that quickly generates vascular timber that resemble actual human blood vessel networks, and converts them into directions for 3D printing. Their algorithm runs roughly 200 instances sooner than prior strategies and might mannequin advanced organ geometries.

To make sure even blood distribution and structural feasibility, the algorithm integrates fluid dynamics simulations. The designs keep away from vessel collisions and preserve a closed-loop system with one entry and exit. The crew has made the device publicly out there by the open-source SimVascular undertaking.

“It took about 5 hours to generate a pc mannequin of a tree to vascularize a human coronary heart. We had been in a position to get to a density the place any cell within the mannequin would have been about 100 to 150 microns away from the closest blood vessel, which is fairly good,” stated Zachary Sexton, a postdoctoral scholar in Marsden’s lab. “That job hadn’t been accomplished earlier than, and doubtless would have taken months with earlier algorithms.”

Towards Absolutely Purposeful Organs: Overcoming the Remaining Hurdles

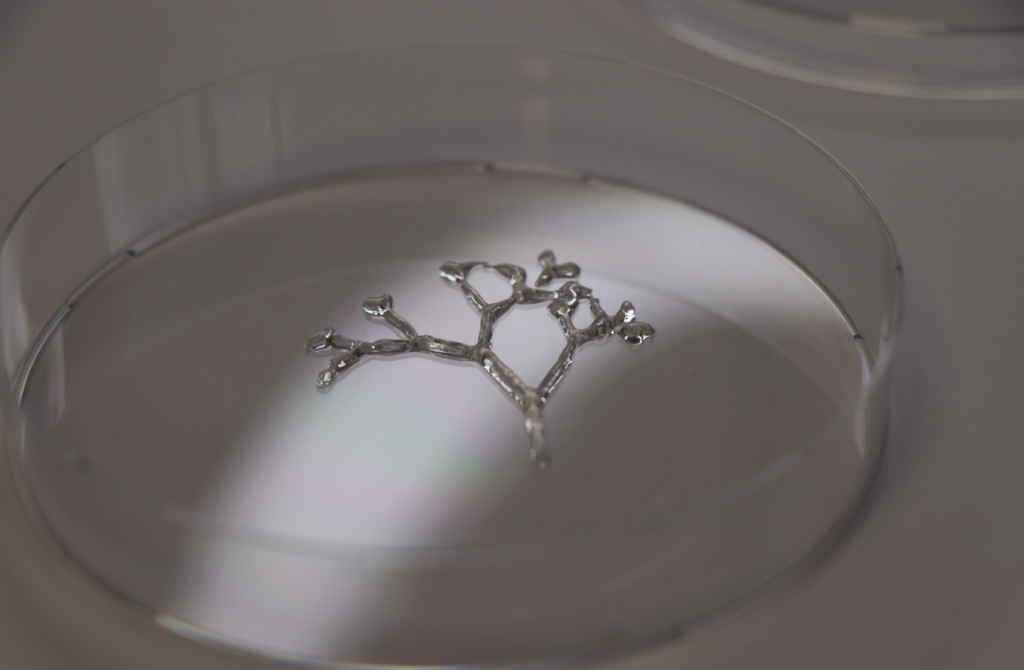

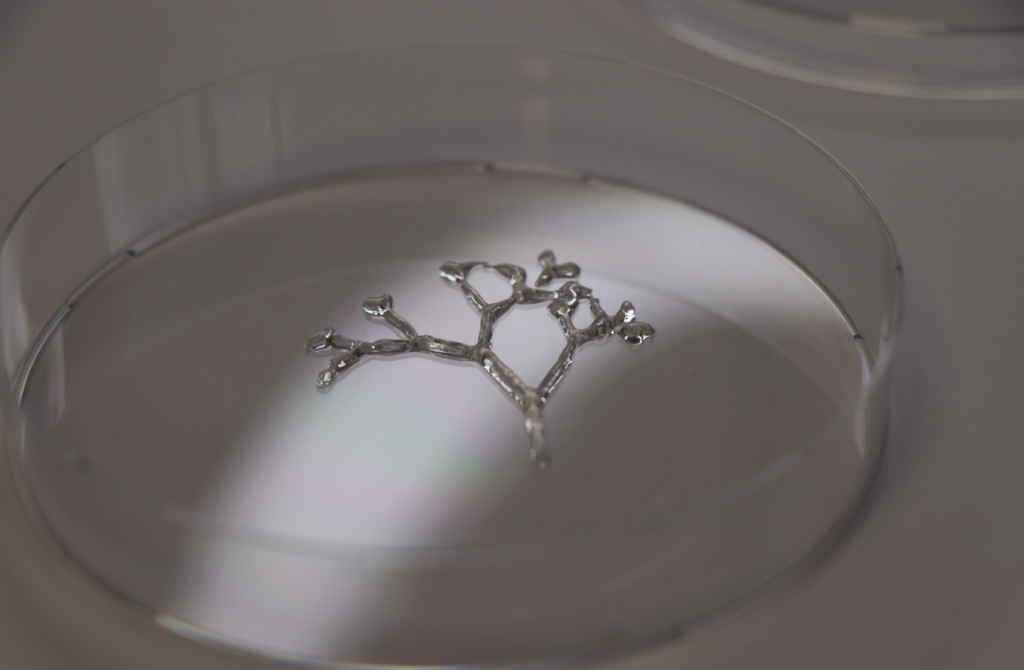

Whereas present 3D printers aren’t but able to printing each characteristic in these dense networks, the crew demonstrated proof of idea by printing a simplified model with 500 branches. Additionally they examined a bioprinted tissue ring embedded with human embryonic kidney cells and 25 vessels. When pumped with a nutrient-rich fluid, the cells close to the printed community remained alive.

“We present these vessels may be designed, printed, and might preserve cells alive,” stated Mark Skylar-Scott, assistant professor of bioengineering and co-senior creator. “We all know that there’s work to do to hurry up the printing, however we now have this pipeline to generate completely different vascular timber very effectively and create a set of directions to print them.”

The researchers famous that these printed networks usually are not but practical blood vessels—they’re structural channels missing muscle, endothelial, and different cell sorts wanted for organic perform. “This is step one towards producing actually advanced vascular networks,” stated Dominic Rütsche, a postdoctoral scholar in Skylar-Scott’s lab and co-first creator. “We are able to print them at never-before-seen complexities, however they don’t seem to be but totally physiological vessels. We’re engaged on that.”

Researchers are additionally investigating methods to stimulate the expansion of the smallest blood vessels—these too tiny or densely packed to be printed instantly—whereas additionally working to reinforce 3D bioprinter pace and precision. Moreover, they concentrate on cultivating the huge variety of cells required to print a whole coronary heart.

Vascular 3D Printing

In 2024, researchers at Harvard’s Wyss Institute for Biologically Impressed Engineering and the John A. Paulson College of Engineering and Utilized Science (SEAS) developed a novel technique for 3D printing vascular networks. Developed from a earlier technique referred to as sacrificial writing in practical tissue, this new technique named coaxial SWIFT (co-SWIFT) permits the creation of interconnected networks of blood vessels embedded inside human cardiac tissue, enhancing the viability of manufacturing implantable human organs.

Again in 2021, Scientists from the Israel Institute of Expertise (Technion) used 3D printing to create a practical community of enormous and small blood vessels able to supplying blood to implanted tissues.

Led by Professor Shulamit Levenberg, this analysis aimed to bypass the necessity for pre-transplant steps and scale back the danger of implant rejection by utilizing patient-specific tissues. After testing the vascular community in rats, the crew deliberate to adapt the know-how for bigger animals, advancing towards lab-grown tissues appropriate for transplantation.

Be a part of our Additive Manufacturing Benefit (AMAA) occasion on July tenth, the place AM leaders from Aerospace, House, and Protection come collectively to share mission-critical insights. On-line and free to attend. Safe your spot now.

Who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business publication to maintain up with the newest 3D printing information.

You may also comply with us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits a mannequin of a vascular tree printed utilizing a 3D bioprinter. Picture through Andrew Brodhead.