Tyler Anderson, Technical Specialist at MatterHackers, takes you thru the method of his creation- The Computerized Print Ejector. This machine will increase your 3D Printer’s autonomy by eradicating your accomplished prints off your print mattress by punching them with a boxing glove.

Posted on December 18, 2015

by

MatterHackers

The aim of this machine is to take away completed objects from the printer in probably the most amusing Rube Goldbergish manner potential. The unique plan was to have a boot swing down and kick the half up and about, however we determined {that a} boxing glove can be extra hilarious. It’s impressed by related issues from outdated cartoons.

The Computerized Print Ejector is made totally from printed elements and issues we had laying round within the warehouse of MatterHackers. The printer being victimized is an OpenBeam Kossel Professional.

I began off by rapidly designing some linkages in Solidworks. The holes match some little ball bearings we had laying round. Every part is held along with M3 bolts. We had an assortment of various sized bearings, so I needed to design elements with a pair completely different gap sizes. The entire ones posted on-line are made to suit 9.5mm outer diameter bearings. The holes additionally embrace an additional 0.3mm to account for the tolerances of printing.

This was a enjoyable challenge as a result of most parts took lower than half-hour to print. I may very well be designing the following factor whereas the final piece was printing. There was no ready. In some instances its higher to plan the whole lot out at first earlier than you construct it, however it may be extra enjoyable to simply dive in and determine issues out as you go alongside. That is what I did with this challenge. I ended up with loads of trashed elements, however who cares.

Every part was printed in PLA since I used to be not anxious about something getting heat.

Advisable Print settings:

- 0.2 mm Layers

- 2 Perimeters

- 30% Infill

As a way to actuate the scissor mechanism, I added a gear to the tip of one of many linkages. I additionally discovered an outdated stepper motor to drive it. I might have used a pastime servo, however the stepper is what we had and its received extra torque anyhow. It additionally conveniently had a small gear already on the shaft.

That is the bracket I designed to carry the motor and the whole lot. The plan was that your entire machine would jut out from the facet of the printer, supported by a size of OpenBeam. As you may see, engineering is an iterative course of.

At this level it turned obvious that solely driving one linkage would not work. Your complete meeting would simply rotate down as an alternative of extending outward. Each of the tip linkages have to be compelled collectively or pulled aside to ensure that the mechanism to work. I added a second gear with inward dealing with tooth. This manner it might be pushed in the other way, forcing the linkages collectively.

Because the gears have completely different radiuses, there are barely completely different gear ratios and one linkage strikes barely farther than the opposite. This makes the entire thing rotate downward a couple of levels when it extends. Oh effectively. Its ok.

The boxing glove mannequin was discovered by way of googling and I modified it in Blender with a sq. gap within the backside to attach it to the arm. This glove turned out to be probably the most troublesome factor to print. Not as a result of it’s a difficult form, however purely due to a sequence of unlucky coincidental points with the printer (a few of which concerned fireplace). When it lastly did print, the help construction underneath the fingers failed, so it would not have fingertips. I made a decision I do not care since you will not see that facet a lot anyhow.

That is after I bumped into the following downside. How do you retain the boxing glove horizontal? I designed a fork formed factor that will slide over the bolts within the heart of the linkages. This makes positive that no matter is connected to the tip stays parallel to the mechanism.

Final step was to connect the beam to the underside and bolt it onto the facet of the printer.

I needed to design some nook brackets as effectively to be able to join the beam to the printer’s body. The mattress is in the way in which so I couldn’t use the official OpenBeam T-Brackets. Luckily I remembered to place some further nuts within the beams after I was constructing the printer. As a result of the factor is mounted perpendicularly on one facet, it punches the objects straight into the tower on the alternative facet. Ultimately I’ll make some 30 diploma / 60 diploma nook brackets so it’ll punch in the appropriate path.

The 24 cm beam is simply barely lengthy sufficient. The print head narrowly misses the glove whereas doing the auto-calibration routine and bumps into it a little bit bit when printing all the way in which out to the sides.

The completed product.

COMPONENT LIST (What you’ll need)

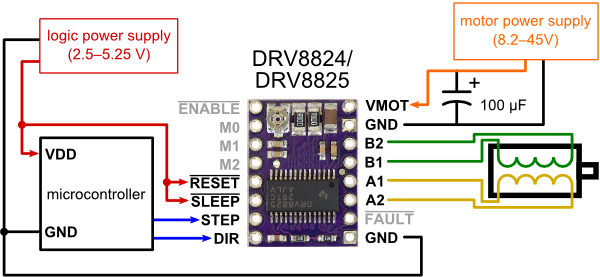

Wiring was fairly simple. I salvaged an outdated Pololu stepper driver from considered one of our spare RAMPS boards and used a ribbon cable with feminine headers to wire it as much as the Brainwave. Right here is the the wiring diagram from Pololu:

I used the 12V rail from the Brainwave for VMOT versus the 24V rail from the Kossel’s PSU. Undecided how a lot present the 12V line was supposed for, however it appears to be doing all proper. The STEP, DIR, and EN traces are hooked as much as OC1B, OC1C, and OC1A, respectively. I did not hassle with microstepping as a result of I wished as a lot torque as potential. A pullup resistor on the EN line is likely to be a good suggestion however I did not embrace it. Right here is the pin configuration added to the Brainwave Professional part of pins.h. I needed to dig round in Arduino’s pins_arduino.h to search out the corresponding pin numbers.

#outline PUNCH_STEP_PIN 26 // OC1B

#outline PUNCH_DIR_PIN 27 // OC1C

#outline PUNCH_ENABLE_PIN 25 // OC1A

The motor I discovered already had a connector on the tip of it, however after I plugged it in it did not need to work. I verified the motor connections utilizing an outdated trick. When you leap two of the traces collectively and the motor turns into tougher to show, you understand they’re related to the identical coil. Rearranged the pins on the connector and the whole lot was good.

The programming can be not difficult. I am together with the attention-grabbing elements right here however the total factor is accessible on GitHub. The firmware is predicated on the OpenBeam department of Marlin firmware. The modifications shouldn’t be arduous to patch into another department of Marlin, although.

I added a brand new G-Code command (G42) that prompts the punching mechanism. It additionally accepts a feedrate (in Hz) so you may inform it how briskly to punch. For instance, “G42 F300”. If you don’t set a velocity, it defaults to 50 steps/s. Right here is the part from the G-Code parser in Marlin_main.cpp:

case 42: // G42

if(code_seen('F')) {

punch(code_value());

} else {

punch(50);

}

That is the precise punching code in pugilism.cpp.

void punch(float velocity)

{

int delayLength = 1000 / (velocity*2);

SERIAL_ECHOLN("WHAM!");

// Allow driver

digitalWrite(PUNCH_ENABLE_PIN, LOW);

// Set path

digitalWrite(PUNCH_DIR_PIN, HIGH);

// Punch

// Thought: Ramp up velocity

for (int i=0; i

Mainly it prompts the driving force, sends 150 pulses to the step pin, then reverses and disables the driving force. 150 steps appears to be about the appropriate distance for the reason that stepper motor has 200 steps/revolution and I might inform from transferring the linkage by hand that the gear rotates about 3/4 of a flip.

300 steps/s appears to be the best velocity. It’s fast and forceful, however not so quick that it overloads the stepper motor. Generally it skips steps whereas punching however that is superb as a result of it resets its place when it retracts. I had an concept that you may get extra energy by accelerating as an alternative of punching at a continuing velocity. This would not be arduous to implement however I have never accomplished it but.

Try the challenge web page at hackaday.io for future updates to this challenge.

Comfortable Printing Punching!