Researchers from the Nationwide College of Singapore (NUS) have developed a 3D printed, self-powered mechanoluminescent (ML) photonic pores and skin designed for communication and security monitoring in underwater environments. The stretchable system emits gentle in response to mechanical deformation, requires no exterior energy supply, and stays practical underneath situations equivalent to excessive salinity and excessive temperatures.

The findings have been printed in Superior Supplies by Xiaolu Solar, Shaohua Ling, Zhihang Qin, Jinrun Zhou, Quangang Shi, Zhuangjian Liu, and Yu Jun Tan. The analysis was carried out at NUS and Singapore’s Company for Science, Know-how and Analysis (A*STAR).

3D printing stretchable light-emitting skins with auxetic geometry

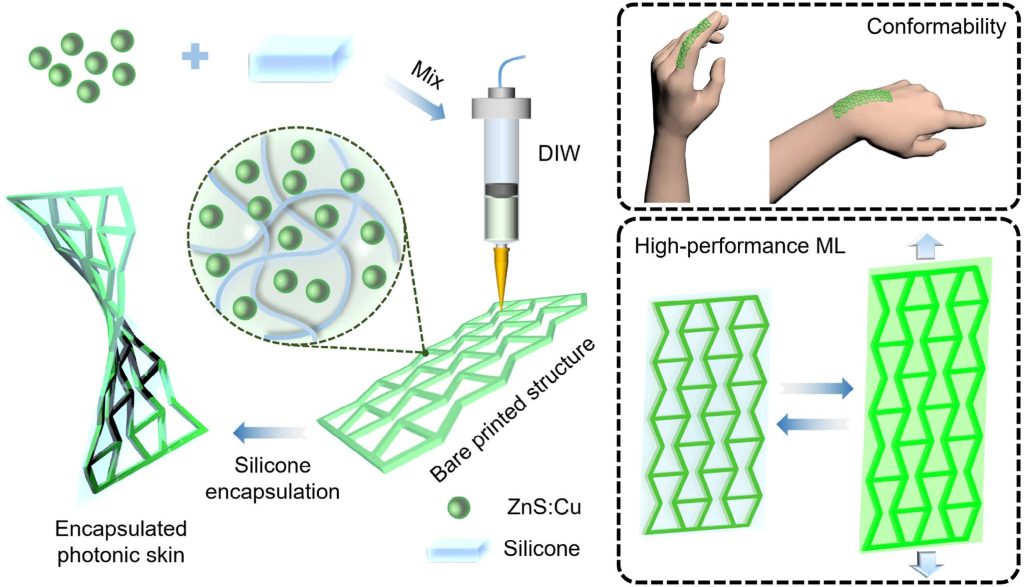

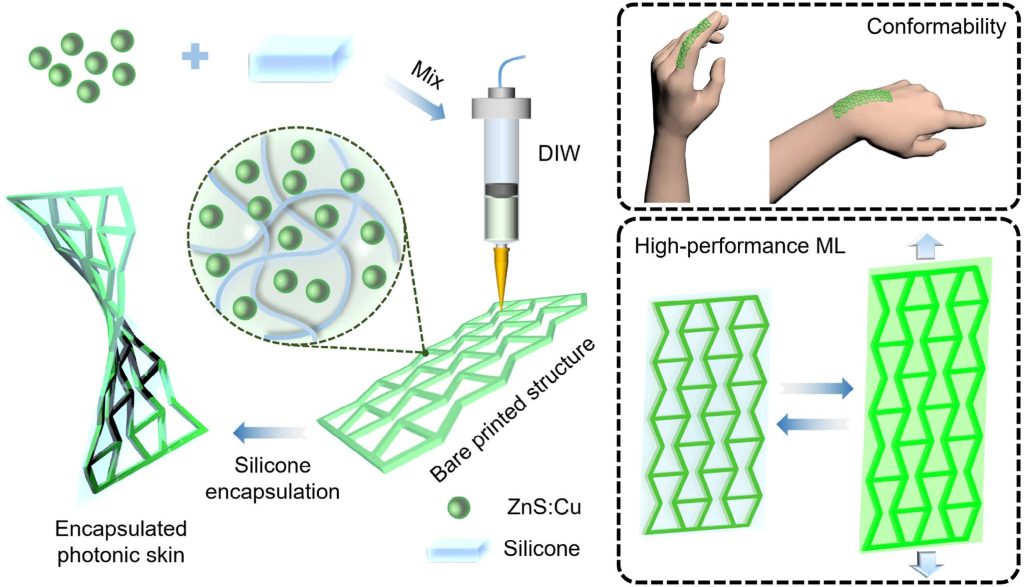

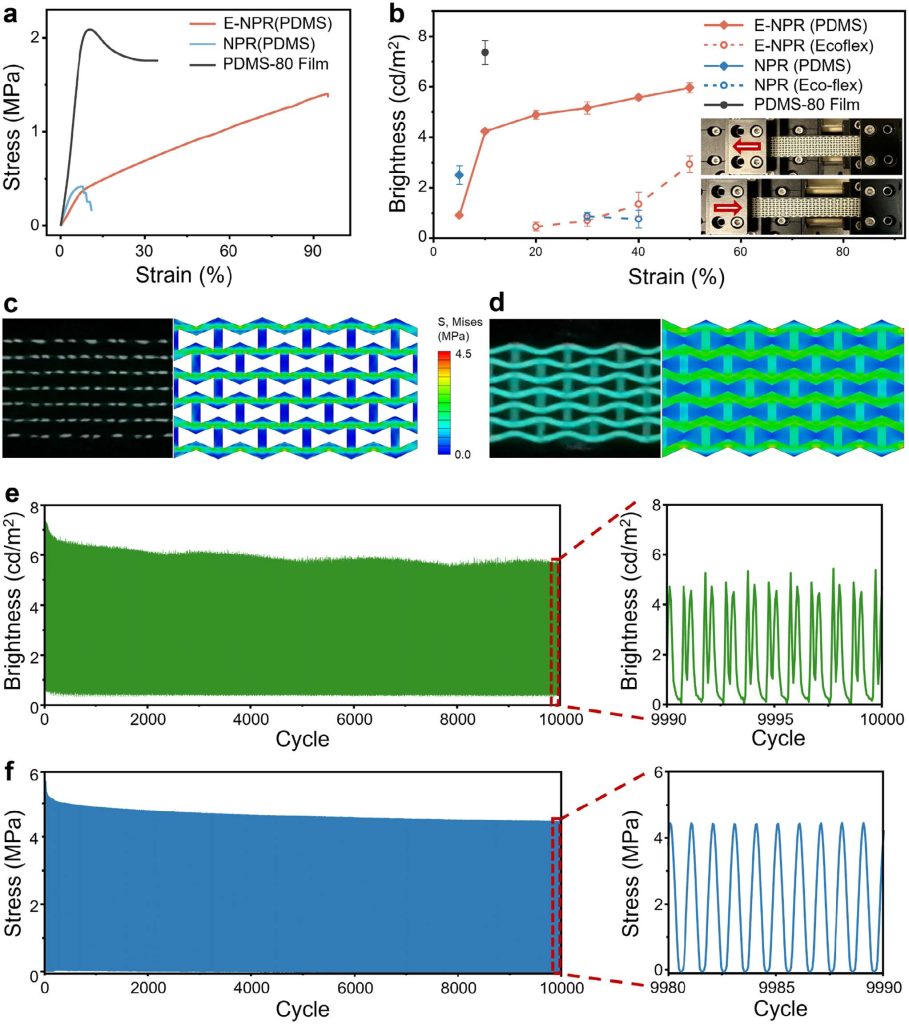

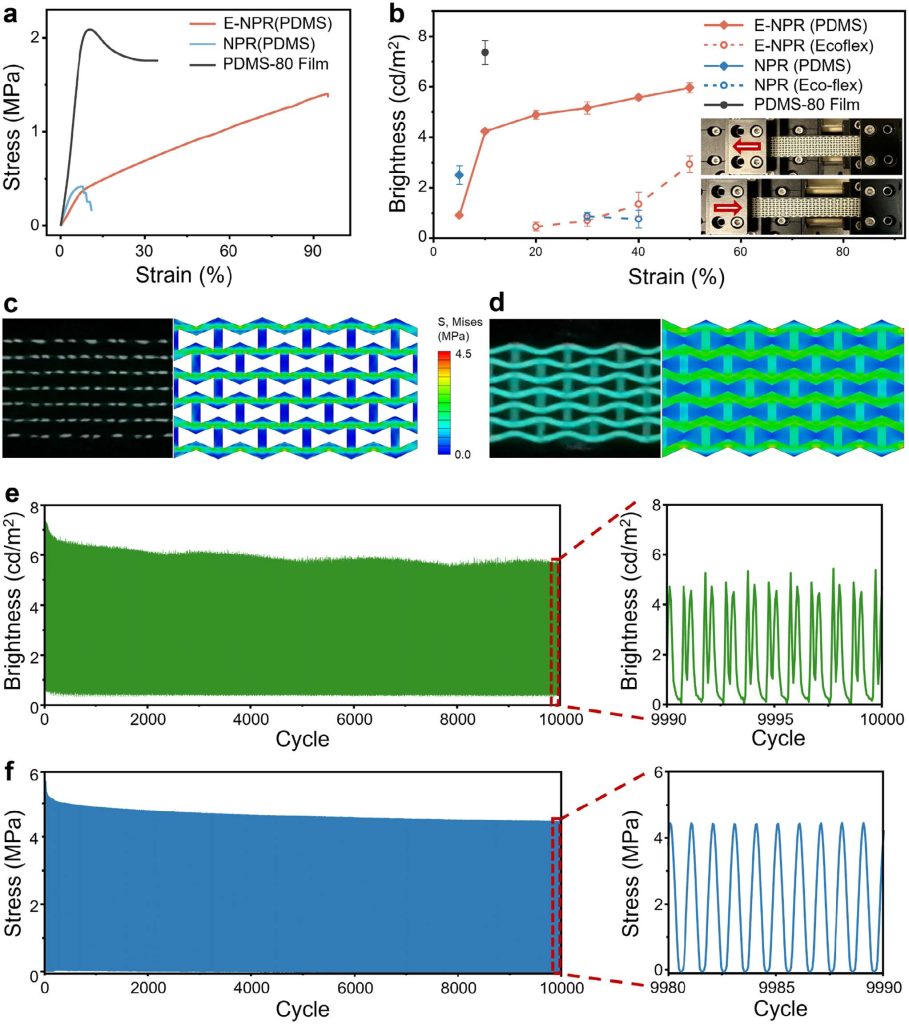

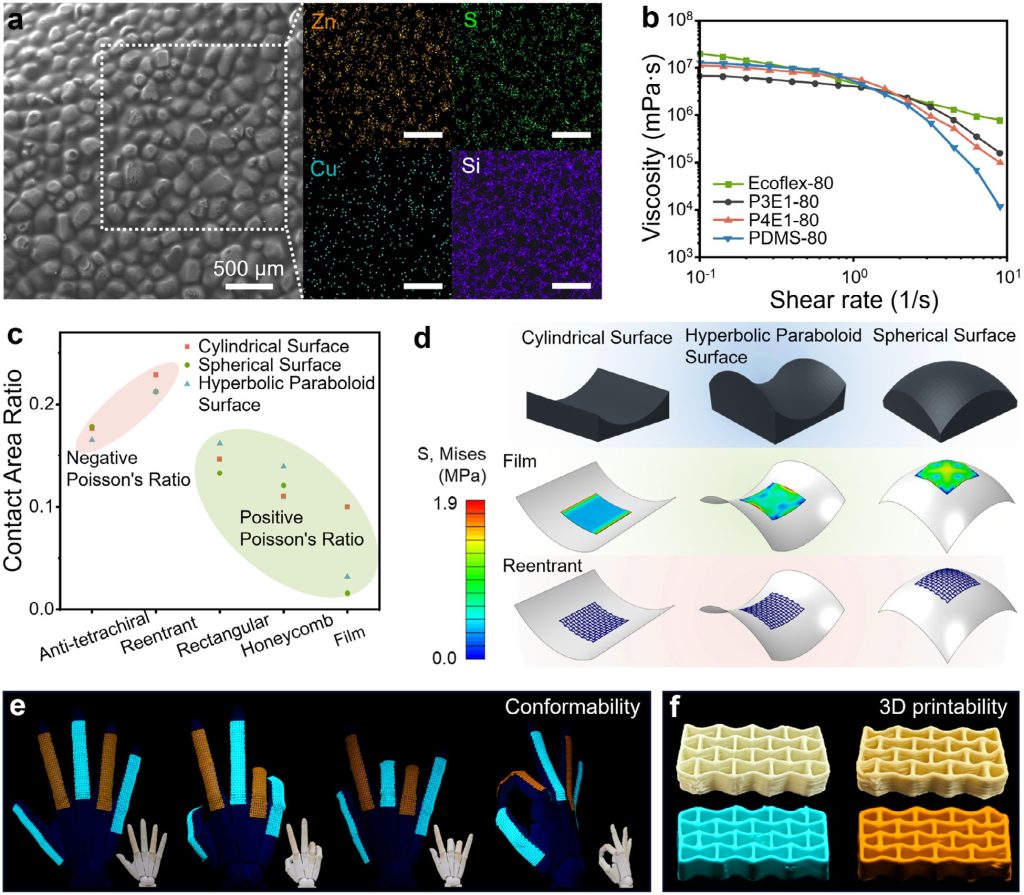

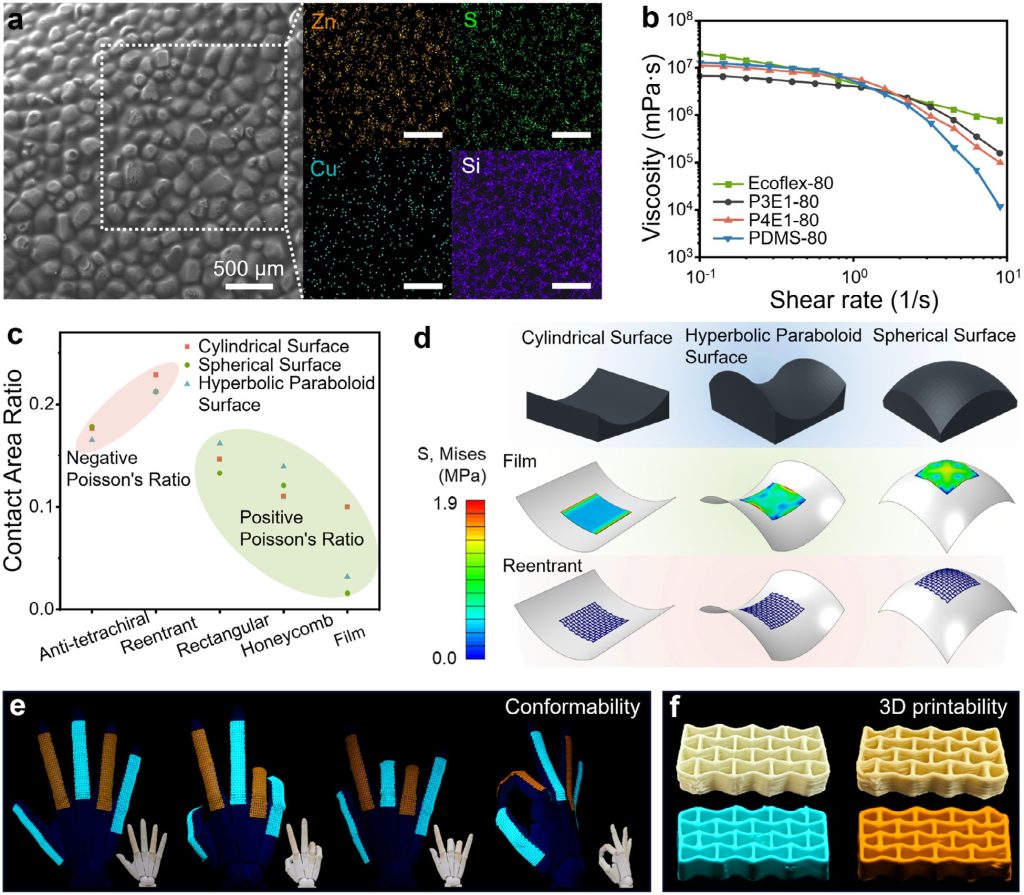

The photonic pores and skin was produced utilizing a 3D printing technique known as direct-ink-writing (DIW), which entails extruding a specifically formulated ink by means of a high-quality nozzle to construct up advanced constructions layer by layer. On this case, the ink was made by mixing tiny particles of zinc sulfide doped with copper (ZnS:Cu), a fabric that glows when stretched, with a versatile silicone rubber. These particles function the energetic ingredient that lights up when the fabric is deformed, whereas the silicone acts as a gentle, stretchable help construction.

To make the system extra adaptable to motion and curved surfaces, like human pores and skin or underwater gear, the researchers printed it utilizing auxetic designs. Auxetic constructions have a uncommon mechanical property referred to as a adverse Poisson’s ratio. In contrast to most supplies, which turn into thinner when stretched, auxetic designs develop laterally underneath stress. This makes them excellent for conforming to curved or irregular surfaces, equivalent to joints, versatile robots, or underwater gear, with out wrinkling or detaching.

Encapsulating the printed pores and skin in a transparent silicone layer additional improves efficiency by distributing mechanical stress evenly. This prevents localized tearing and ensures that the sunshine emission stays shiny and uniform, even after 10,000 cycles of stretching and enjoyable. In earlier stretchable light-emitting units, uneven stress typically led to dimming, flickering, or early materials failure.

Underwater signaling, robotics, and fuel leak detection

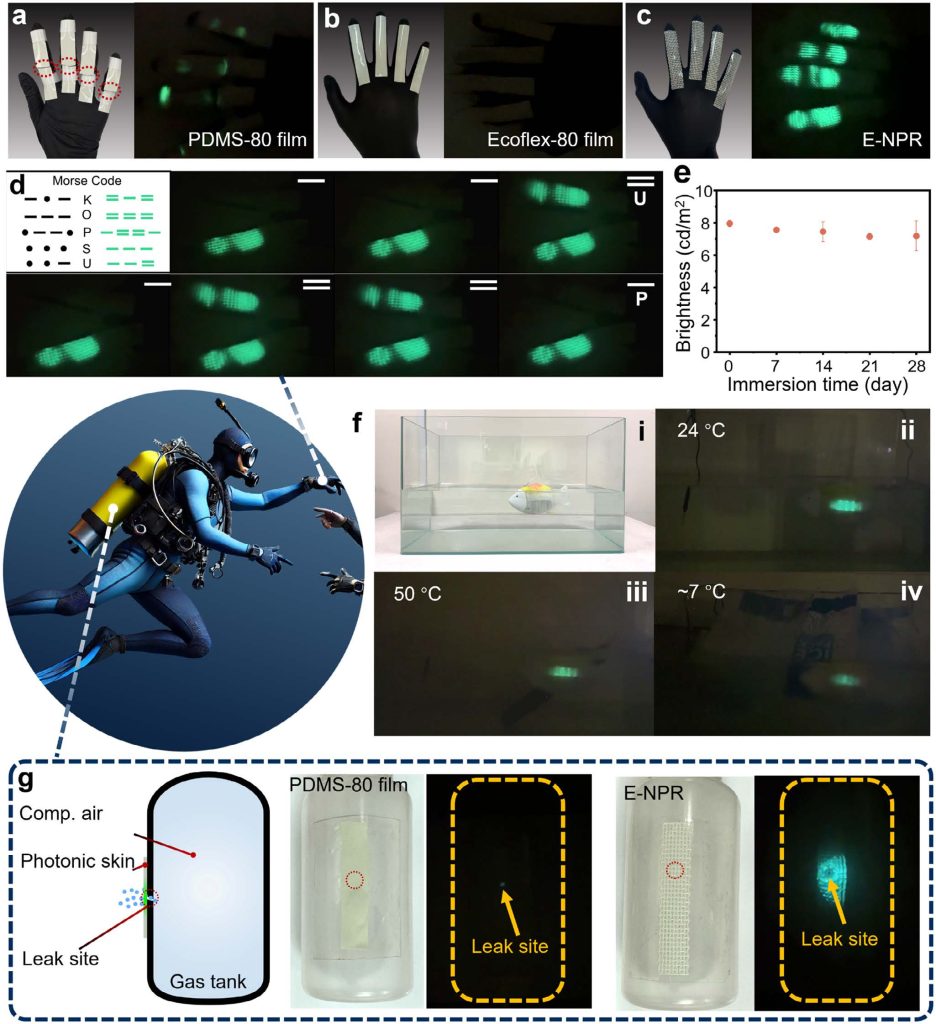

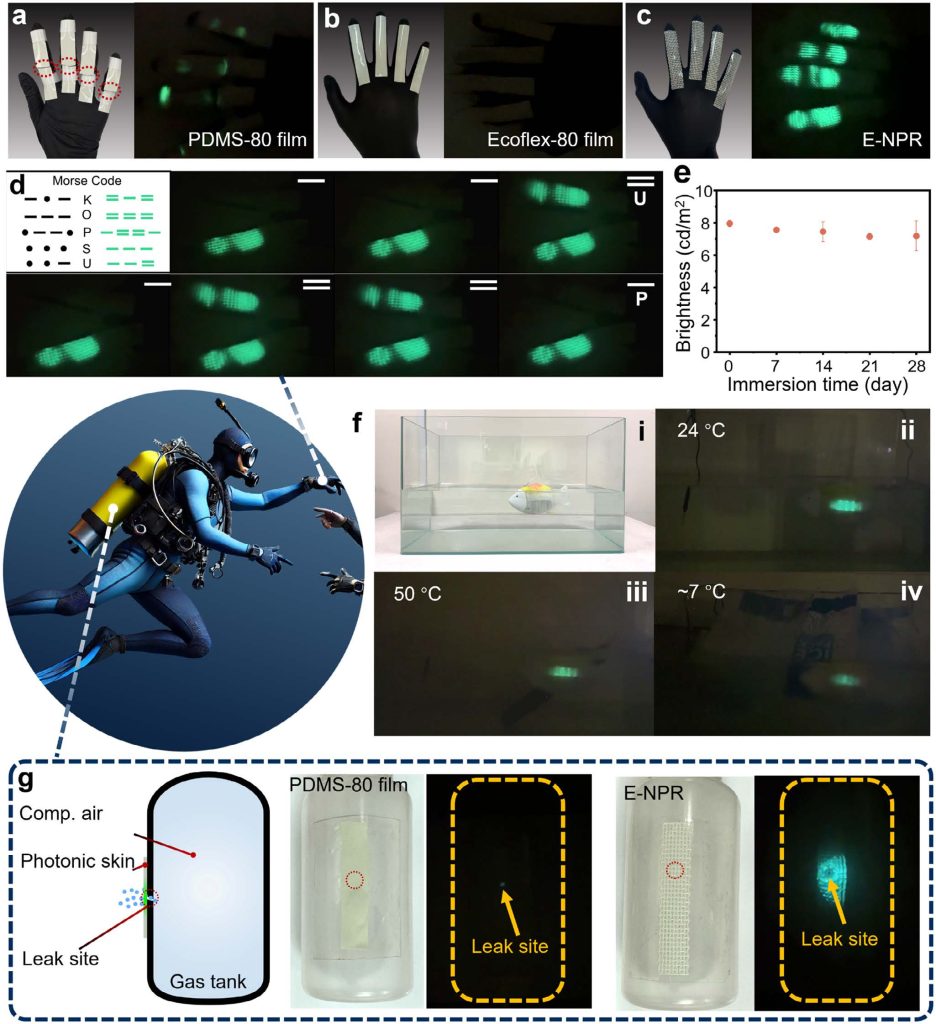

The staff demonstrated a number of purposes for the photonic pores and skin. When built-in into wearable gloves, the pores and skin enabled light-based Morse code communication by means of easy finger gestures. Bending a number of fingers activated the mechanoluminescence, emitting seen flashes that corresponded to messages equivalent to “UP,” “OK,” or “SOS.” The system remained absolutely practical when submerged in chilly water (~7°C), simulating deep-sea situations.

In a separate take a look at, the pores and skin was utilized to a fuel tank mock-up to watch for leaks. A pinhole defect was coated with the printed pores and skin and sealed utilizing stretchable tape. When pressurized air escaped by means of the leak, the localized mechanical pressure brought about a shiny cyan glow on the precise leak web site, providing a passive, electronics-free different to standard fuel sensors.

To check efficiency on gentle and cell platforms, the researchers additionally mounted the photonic pores and skin onto a robotic fish. Because the robotic swam by means of water tanks at completely different temperatures (24°C, 50°C, and seven°C), the pores and skin continued to gentle up reliably, demonstrating its resilience and utility for marine robotics.

Towards electronics-free underwater communication

Whereas LEDs and optical fibers are broadly utilized in underwater lighting programs, their dependence on inflexible type elements and exterior energy makes them unsuitable for dynamic, versatile purposes. In distinction, the stretchable ML photonic pores and skin developed by NUS researchers gives a self-powered, adaptable different for diver signaling, robotic inspection, and leak detection, doubtlessly remodeling the toolkit for underwater communication and security programs.

Future instructions embody enhanced sensory integration and robotic purposes, because the staff continues exploring sturdy photonic programs for excessive environments.

The rise of 3D printed multifunctional supplies

The event of the photonic pores and skin displays a broader development in additive manufacturing towards multifunctional supplies, constructions that serve greater than a structural position. Researchers are more and more utilizing multimaterial 3D printing to embed sensing, actuation, and signaling capabilities straight into units. For instance, latest work by SUSTech and Metropolis College of Hong Kong on thick-panel origami constructions confirmed how multimaterial printing can allow massive, foldable programs with excessive energy and movement management. These and different advances, together with conductive FDM processes and Lithoz’s multimaterial ceramic instruments, mark a shift towards printing whole programs. The NUS photonic pores and skin suits squarely inside this motion, combining mechanical adaptability, environmental sturdiness, and real-time optical output right into a single printable type.

Learn the total article in Superior Supplies

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the newest 3D printing information.

You too can comply with us on LinkedIn and subscribe to the 3D Printing Trade YouTube channel to entry extra unique content material.

At 3DPI, our mission is to ship high-quality journalism, technical perception, and trade intelligence to professionals throughout the AM ecosystem.

Assist us form the way forward for 3D printing trade information with our 2025 reader survey.

Featured picture reveals a schematic of the 3D printed mechanoluminescent photonic pores and skin exhibiting fabrication steps and light-weight emission underneath deformation. Picture by way of Solar et al., Superior Supplies.