Engineers at MIT have devised an ingenious new technique to produce synthetic muscle tissues for delicate robots that may flex in a couple of route, just like the advanced muscle tissues within the human physique.

The crew leveraged 3D printing and muscle cells derived from people and mice to develop a man-made construction that pulls concentrically and radially, just like how the human iris dilates and constricts the pupil.

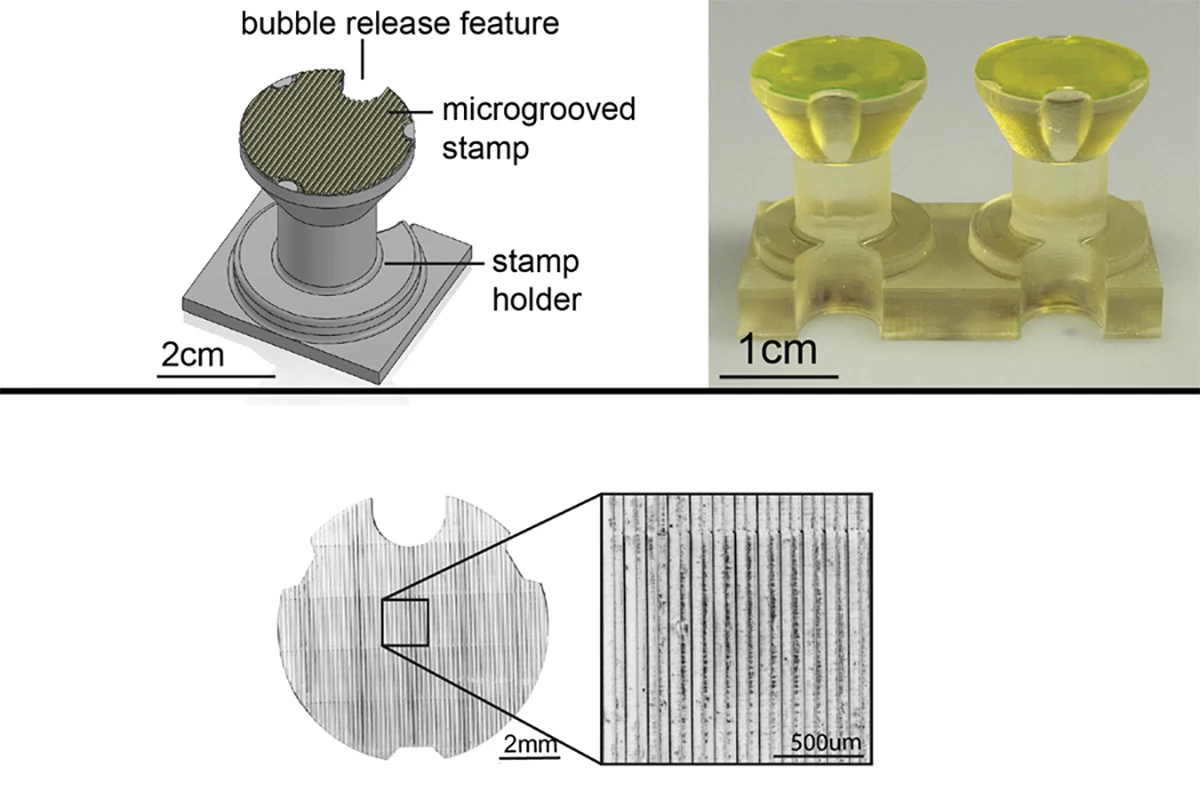

The researchers are calling this methodology ‘stamping,’ as a result of it entails 3D printing a stamp patterned with microscopic grooves solely giant sufficient to every home a person cell. Apparently, it was impressed by the best way Jell-O molds form gelatinous desserts.

Subsequent, they pressed the stamp right into a hydrogel – an artificial equal of organic tissue that supplied a versatile, water-containing matrix for actual cells.

Ritu Raman et al / MIT

These hydrogel-laden grooves had been then seeded with actual muscle cells that had been genetically engineered to reply to gentle. They grew alongside these grooves into fibers over the course of a day, and subsequently right into a muscle roughly the identical dimension as a human iris.

The researchers then stimulated this synthetic muscle with pulses of sunshine, and it contracted in a number of instructions similar to an actual human iris.

“On this work, we wished to indicate we are able to use this stamp strategy to make a ‘robotic’ that may do issues that earlier muscle-powered robots can’t do,” defined Ritu Raman, who co-authored the paper describing this methodology that appeared final week in Biomaterials Science.

This might unlock new capabilities in delicate robots, which function extra mechanically as a result of they’re fitted with rigid elements. “As an alternative of utilizing inflexible actuators which are typical in underwater robots, if we are able to use delicate organic robots, we are able to navigate and be way more energy-efficient, whereas additionally being utterly biodegradable and sustainable,” Raman famous.

The stamping methodology is notable not solely due to what it permits, but additionally as a result of it is cost-effective and simply accessible. The MIT crew used high-end precision 3D printers on the college for this work, however Raman says equally intricate stamps could possibly be produced utilizing consumer-grade printers as properly. The stamps will also be cleaned and reused to create extra synthetic muscle tissues.

The researchers plan to strive stamping with different cell sorts, and have a look at different muscle tissues they’ll replicate for quite a lot of robotic capabilities.

I am eager to see how that is used to develop extra superior delicate robots within the close to future. Earlier this yr, we noticed Cornell College researchers provide you with ‘robotic blood’ – a Redox Movement Battery system that may be embedded in robots with out the necessity for inflexible buildings. Between these two improvements, we’re inching nearer to creating robots that may squeeze into tight spots and examine leaky undersea pipes, or conduct difficult search-and-rescue operations.

Supply: MIT Information