Researchers from the Division of Mechanical Engineering at Virginia Tech have launched a steady fiber reinforcement (CFR) deposition device designed for multi-axis 3D printing, considerably enhancing mechanical efficiency in composite buildings. Led by Kieran D. Beaumont, Joseph R. Kubalak, and Christopher B. Williams, and printed in Springer Nature Hyperlink, the examine demonstrates an 820% enchancment in most load capability in comparison with standard planar quick carbon fiber (SCF) 3D printing strategies. This device integrates three key capabilities: dependable fiber reducing and re-feeding, in situ fiber quantity fraction management, and a slender collision quantity to assist complicated multi-axis toolpaths.

The newly developed deposition device addresses crucial challenges in CFR additive manufacturing. It’s able to reducing and re-feeding steady fibers throughout journey actions, a operate required to create complicated geometries with out materials tearing or print failure. In situ management of fiber quantity fraction can also be achieved by adjusting the polymer extrusion fee. A slender geometry minimizes collisions between the device and the printed half throughout multi-axis actions.

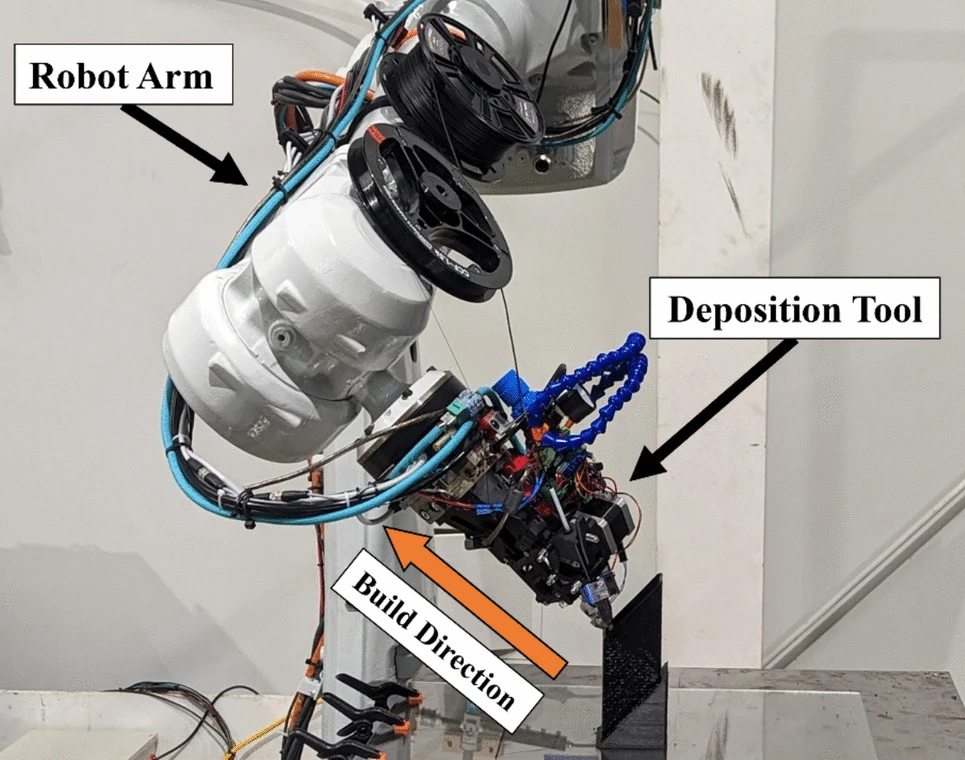

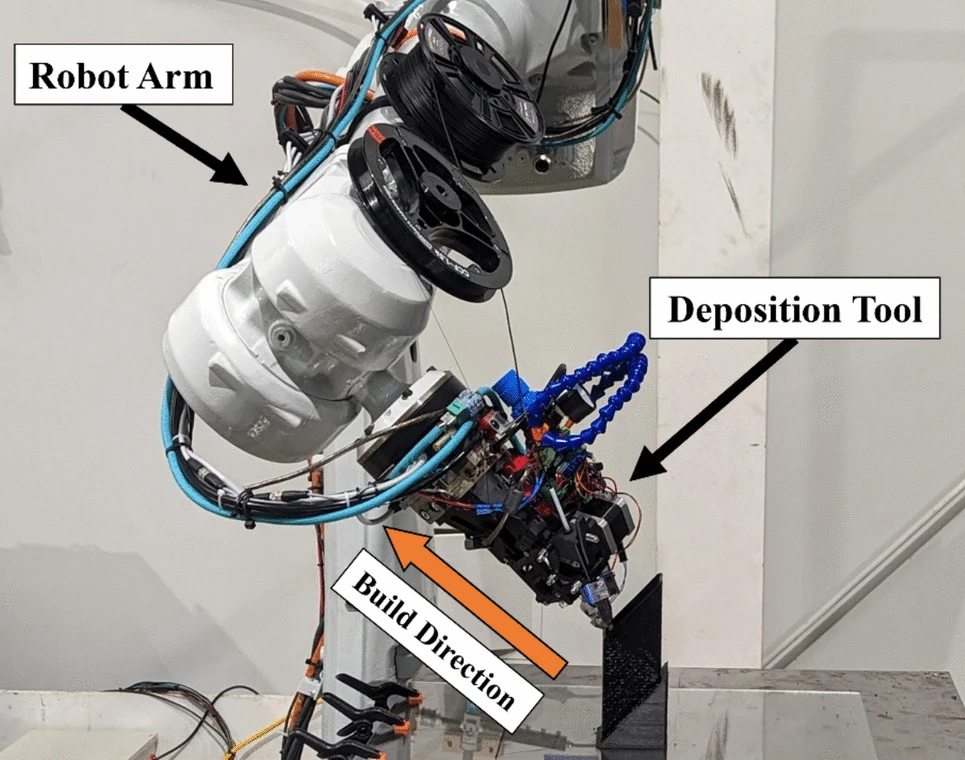

The researchers designed the device to co-extrude a thermoplastic polymer matrix with a steady carbon fiber (CCF) towpreg. This method allowed dependable fiber re-feeding after every minimize and enabled printing with variable fiber content material inside a single half. The device’s slender collision quantity helps elevated vary of movement for the robotic arm used within the experiments, permitting alignment of fibers with three-dimensional load paths in complicated buildings.

Mechanical Testing Confirms Load-Bearing Enhancements

Mechanical exams evaluated the impression of steady fiber reinforcement on polylactic acid (PLA) components. In tensile exams, samples bolstered with steady carbon fibers achieved a tensile power of 190.76 MPa and a tensile modulus of 9.98 GPa within the fiber route. These values examine to 60.31 MPa and three.01 GPa for neat PLA, and 56.92 MPa and 4.30 GPa for components containing quick carbon fibers. Extra exams assessed intra-layer and inter-layer efficiency, revealing that the continual fiber–bolstered materials had lowered mechanical properties in these orientations. In comparison with neat PLA, intra-layer tensile power and modulus dropped by 66% and 63%, respectively, and inter-layer power and modulus decreased by 86% and 60%.

Researchers printed curved tensile bar geometries utilizing three strategies to judge efficiency in components with three-dimensional load paths: planar quick carbon fiber–bolstered PLA, multi-axis quick fiber–bolstered samples, and multi-axis steady fiber–bolstered composites. The multi-axis quick fiber–bolstered components confirmed a 41.6% enhance in most load in comparison with their planar counterparts. In the meantime, multi-axis steady fiber–bolstered components absorbed masses 8.2 instances increased than the planar quick fiber–bolstered specimens. Scanning electron microscopy (SEM) photos of fracture surfaces revealed fiber pull-out and restricted fiber-matrix bonding, significantly in samples with steady fibers.

To confirm the device’s fiber reducing and re-feeding functionality, the researchers printed a 100 × 150 × 3 mm rectangular plaque that required 426 reducing and re-feeding operations throughout six layers. The deposition device achieved a 100% success fee, demonstrating dependable reducing and re-feeding with out fiber clogging. This reliability is crucial for manufacturing complicated buildings that require frequent journey actions between deposition paths.

In situ fiber quantity fraction management was validated by way of printing an oblong prism pattern with various polymer feed charges, highway widths, and layer heights. The fiber quantity fractions achieved in several sections of the half had been 6.51%, 8.00%, and 9.86%, as measured by cross-sectional microscopy and picture evaluation. Though decrease than some literature reviews, the researchers attributed this to the particular mixture of device geometry, polymer-fiber interplay time, and print pace.

The device makes use of Anisoprint’s CCF towpreg, a pre-impregnated steady carbon fiber product with a fiber quantity fraction of 57% and a diameter of 0.35 mm. 3DXTECH’s black PLA and SCF-PLA filaments had been chosen to make sure constant matrix properties and keep away from the affect of pigment variations on mechanical testing. The experiments had been carried out utilizing an ABB IRB 4600–40/2.55 robotic arm geared up with a device changer for switching between the CFR-MEX deposition device and a regular MEX device with an elongated nozzle for planar prints.

Context Inside Present Analysis and Future Instructions

Steady fiber reinforcement in additive manufacturing has beforehand demonstrated vital enhancements partially efficiency, with some research reporting tensile strengths of as much as 650 MPa for PLA composites bolstered with steady carbon fibers. Nevertheless, conventional three-axis printing strategies limit fiber orientation to planar instructions, limiting these features to throughout the XY-plane. Multi-axis 3D printing approaches have demonstrated improved load-bearing capability in short-fiber bolstered components. For instance, multi-axis printed samples have proven failure masses a number of instances increased than planar-printed counterparts in strain cap and curved geometry purposes.

Virginia Tech’s device integrates a number of functionalities that earlier instruments in literature couldn’t obtain concurrently. It combines a polymer feeder based mostly on a twin drive extruder, a fiber cutter and re-feeder meeting, and a co-extrusion hotend with adjustable interplay time for fiber-polymer bonding. A needle-like geometry and exterior pneumatic cooling pipes scale back the danger of collision with the printed half throughout multi-axis reorientation. Measured collision quantity angles had been 56.2° for the complete device and 41.6° for the hotend meeting.

Regardless of these advances, the researchers recognized challenges associated to weak bonding between the fiber and the polymer matrix. SEM photos confirmed restricted impregnation of the polymer into the fiber towpreg, with the fiber-matrix interface remaining a key space for future work. The examine highlights that optimizing fiber tow sizing and bettering the fiber-polymer interplay time throughout printing might improve inter-layer and intra-layer efficiency. The outcomes additionally counsel that superior toolpath planning algorithms might additional leverage the device’s skill to align fiber deposition alongside three-dimensional load paths, bettering mechanical efficiency in practical components.

The publication in Springer Nature Hyperlink paperwork the complete design, validation experiments, and mechanical characterization of the CFR-MEX device. The work provides to a rising physique of analysis on multi-axis additive manufacturing, significantly in combining steady fiber reinforcement with complicated geometries.

Take the 3DPI Reader Survey — form the way forward for AM reporting in beneath 5 minutes.

Prepared to find who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business publication to remain up to date with the most recent information and insights.

Featured photograph reveals the six Diploma-of-Freedom Robotic Arm printing a multi-axis geometry. Photograph through Springer Nature Hyperlink.