Good manufacturing is quick turning into a strategic crucial for industrial leaders in america, in line with Deloitte’s 2025 Good Manufacturing Survey.

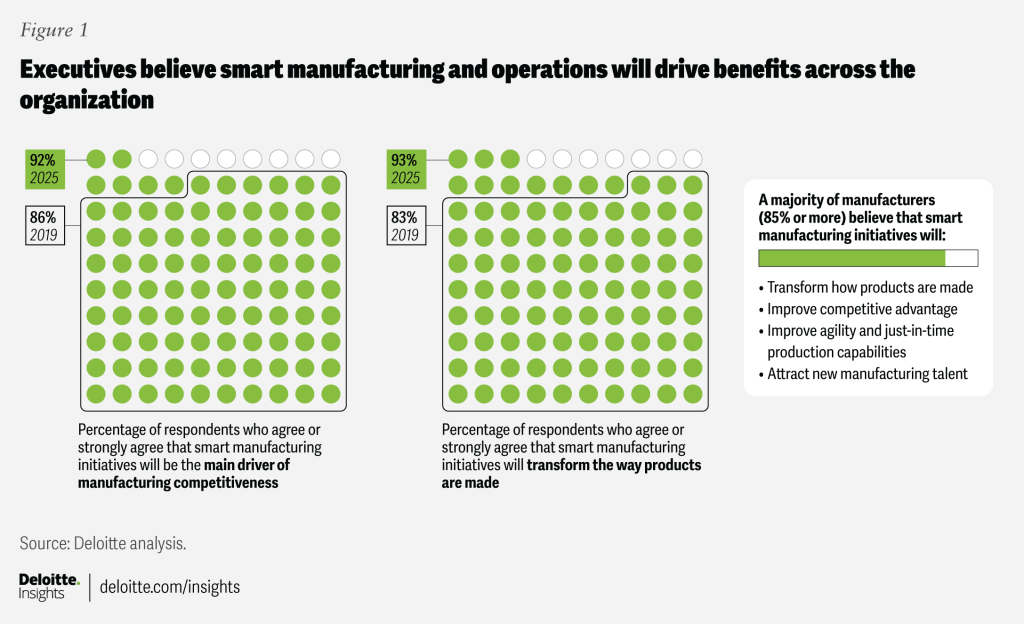

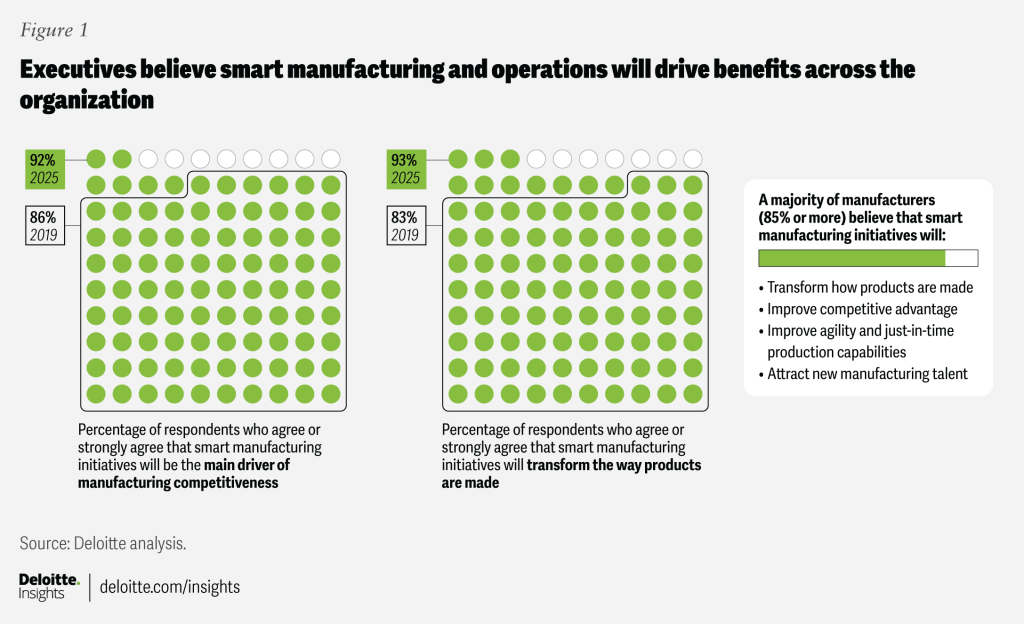

Performed between August and September 2024 and involving 600 senior executives from massive manufacturing corporations, the examine exhibits that 92% of respondents view good manufacturing as the first driver of competitiveness over the subsequent three years. This exhibits a rise of 6 share factors (PP) since 2019. About 85% of respondents are satisfied that good manufacturing will reshape manufacturing processes, increase agility, and entice high expertise to the sector.

Efficiency positive factors drive rising funding urge for food

Corporations already implementing good manufacturing are seeing clear efficiency advantages, the report notes. On common, producers reported 10% to twenty% enhancements in manufacturing output, 7% to twenty% positive factors in worker productiveness, and as much as 15% extra capability unlocked.

Almost half of the executives recognized operational advantages as the first motive for adopting these initiatives, whereas 44% highlighted monetary positive factors. Reflecting this optimism, 78% of respondents mentioned they’re dedicating over 20% of their enchancment budgets to good manufacturing, and 88% count on investments to stay regular or rise within the coming yr. Producers are specializing in course of and bodily automation and on synchronizing manufacturing facility operations to drive these enhancements.

Efforts to modernize factories embody important spending on automation gear, sensors, and imaginative and prescient programs. Cloud computing, knowledge analytics, and industrial IoT are broadly used, with 57% of corporations utilizing cloud options and 46% deploying IIoT. Adoption of unified knowledge fashions and customary architectural requirements is rising, serving to corporations handle knowledge extra successfully and reply shortly to operational wants.

Even so, the report suggests many producers are nonetheless growing their synthetic intelligence (AI) capabilities. Solely 29% have adopted AI or machine studying at scale, whereas 24% have begun utilizing generative AI. Pilot tasks are underway, displaying cautious however rising curiosity in making use of AI to decision-making processes.

Navigating dangers and workforce wants

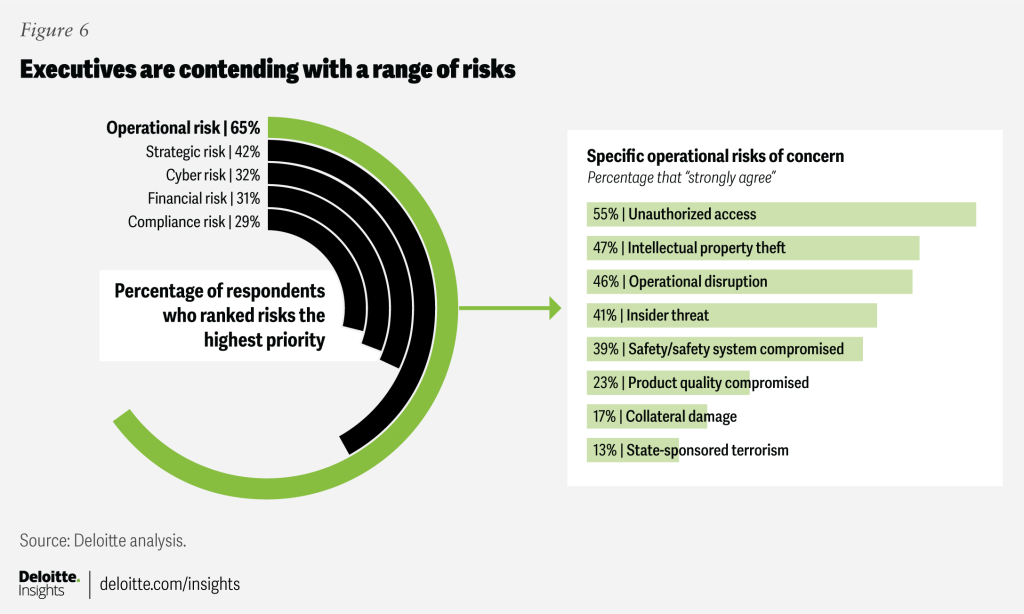

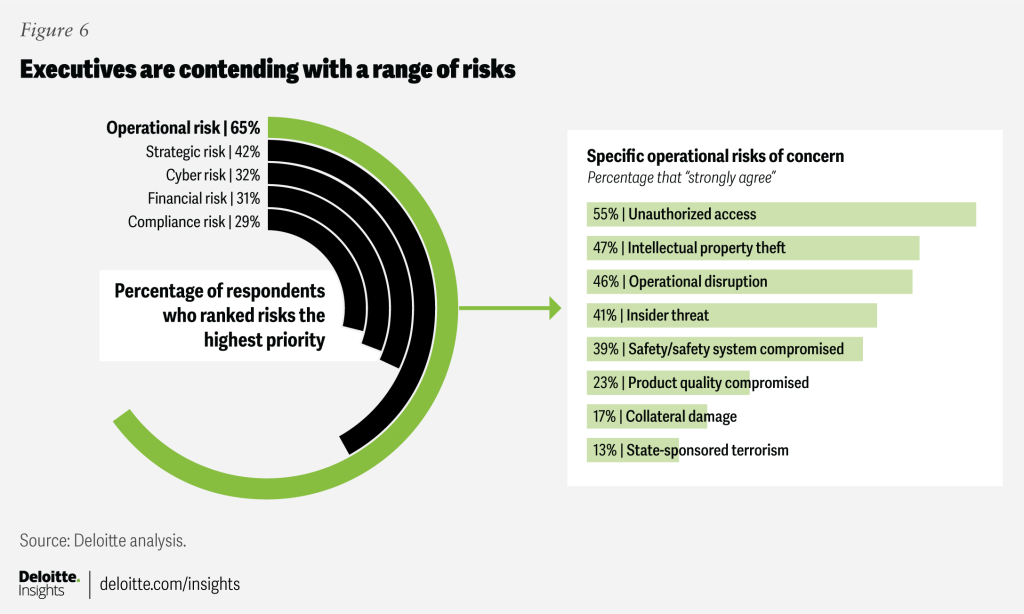

Whereas the advantages are clear, scaling good manufacturing comes with challenges. 65% of executives cited operational threat as a high concern, together with disruptions to enterprise and potential monetary losses from failed tasks.

Cybersecurity can also be a urgent problem, with 91% of producers reporting no less than one cybersecurity breach prior to now yr, in line with Deloitte’s 2024 International Way forward for Cyber survey. In the meantime, the expertise scarcity looms massive with the sector anticipated to wish 3.8 million new staff by 2033. In response, 48% of firms have launched coaching applications for good manufacturing, however Deloitte’s survey suggests human capital stays the least developed space.

The expertise hole extends past the manufacturing facility flooring, with many firms struggling to fill data expertise (IT), OT, and knowledge science roles. Consequently, round 70% of producers are turning to third-party suppliers to satisfy their cybersecurity and knowledge calls for.

Inside manufacturing corporations, efforts to handle this transformation are evolving. Greater than half of respondents have established devoted groups to drive good manufacturing initiatives, whereas 45% are specializing in constructing communication processes to assist workers and prospects adapt to those modifications.

Management for these initiatives usually cuts throughout departments, with round half of the respondents saying that operations heads, together with Chief Working Officers (COO), are spearheading efforts. Expertise leaders, equivalent to Chief Expertise Officers (CTO), take the lead in about 38% of circumstances.

What started as an aspirational thought in 2017 has change into a sensible roadmap for enhancing competitiveness, Deloitte’s report concludes. Good manufacturing is not about chasing the newest expertise pattern, it’s about focused investments in knowledge, core programs, and workforce improvement to unlock operational and monetary worth.

Good manufacturing efforts in AM

Deloitte’s findings resonate with the adoption of data-driven 3D printing and digital manufacturing facility options, which carry agility and resilience to fashionable manufacturing.

For instance, Hexagon’s Digital Manufacturing unit unveiled on the Farnborough Worldwide Air Present 2024, permits producers to create digital replicas of their manufacturing facility flooring and combine digital twins of equipment, optimizing layouts and workflows. Developed by means of Hexagon’s Manufacturing Intelligence division, it combines 3D metrology expertise with cloud-based collaboration instruments to allow distant monitoring, decision-making, and smarter operations.

The system guarantees substantial financial savings by means of decreased planning errors and streamlined manufacturing agility, whereas additionally minimizing the necessity for on-site coaching and journey. Designed to combine with current workflows and appropriate with in style CAD and BIM software program, Digital Manufacturing unit creates a data-driven manufacturing atmosphere that helps the shift to smarter, extra sustainable factories.

In 2020, High quality assurance (QA) software program developer Sigma Labs partnered with superior manufacturing agency IN4.OS to construct “Good Factories of the Future,” integrating DMG MORI’s LASERTEC steel 3D printers and Sigma’s PrintRite3D expertise to make sure high-quality manufacturing. These cyber-physical amenities goal to supply protection and aerospace corporations with scalable, location-agnostic, trade 4.0 manufacturing for mission-critical components.

On this setup, the software program developer’s PrintRite3D QA software program allowed for unified high quality management and versatile machine integration, whereas distant monitoring provided enhanced flexibility and resilience. Based on IN4.OS CEO R J Singh, PrintRite3D is important for making additive manufacturing mainstream and dependable for vital manufacturing, working seamlessly with DMG MORI’s superior programs in these good factories.

Take the 3DPI Reader Survey — form the way forward for AM reporting in below 5 minutes.

What 3D printing developments must you be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits that executives agree good manufacturing will increase competitiveness and remodel manufacturing. Picture through Deloitte.