3D printer OEM 3D Programs’ Software Innovation Group (AIG) is working with researchers from Penn State College (PSU), Arizona State College (ASU) and NASA Glenn Analysis Middle to develop superior thermal administration methods for spacecraft.

The NASA-sponsored tasks are utilizing 3D Programs’ Direct Steel Printing (DMP) expertise and Oqton’s 3DXpert software program to supply high-performance radiators and warmth pipes created from titanium and nickel-titanium alloys.

By embedding warmth pipes and shape-memory alloy parts instantly into radiators by way of 3D printing, the group is addressing the load and manufacturing complexity of conventional thermal methods, making future area missions cheaper and succesful.

“Our long-standing R&D partnership with 3D Programs has enabled pioneering analysis for using 3D printing for aerospace purposes,” stated Alex Rattner, Affiliate Professor at PSU. “The collective experience in each aerospace engineering and additive manufacturing is permitting us to discover superior design methods which can be pushing the boundaries of what’s thought of state-of-the-art.”

Excessive-efficiency cooling for spacecraft

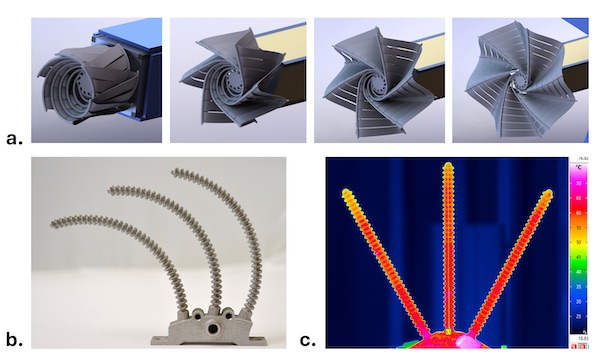

One space of focus includes 3D printing titanium warmth rejection radiators with embedded high-temperature passive warmth pipes. Historically, creating these inside porous wick buildings includes a number of manufacturing steps to permit fluid to flow into and switch warmth. The group used 3DXpert software program to embed these porous buildings instantly into the titanium warmth pipe partitions, eradicating further steps and lowering variability.

These monolithic titanium radiators operated efficiently at temperatures of 230°C and demonstrated a 50% discount in weight, attaining 3 kg per sq. m. in comparison with greater than 6 kg per sq. m. in typical methods. This method meets NASA’s targets for enhanced warmth switch effectivity and decrease launch prices.

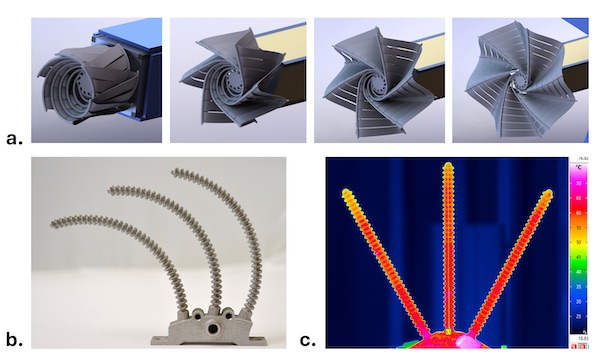

One other undertaking examines how form reminiscence alloys (SMAs) can be utilized to create deployable radiators. Researchers produced one of many first useful components created from nickel-titanium (nitinol) that may be passively actuated and deployed when heated. The group designed a deployable spoke construction in nitinol utilizing 3DXpert, leading to a sixfold enhance in deployed-to-stowed space ratio, together with a weight discount of greater than 70%, from 19 kg per sq. m. to lower than 6 kg per sq. m.

These SMA-based radiators can deploy in area with out the necessity for mechanical actuators, providing extra dependable thermal administration for high-power CubeSat and small satellite tv for pc missions. Pictures and take a look at information from Penn State affirm the prototypes’ thermal efficiency and their capacity to face up to harsh area circumstances.

In accordance with Analysis and Markets referred by 3D Programs, the aerospace additive manufacturing sector was valued at $1.2 billion in 2023 and is projected to develop to almost $4 billion by 2030. Over the previous decade, 3D Programs has produced greater than 2,000 titanium and aluminum alloy parts for area missions, reflecting the rising position of additive manufacturing in constructing high-performance, light-weight methods for demanding environments.

Thermal administration options past area

With additively manufactured components, warmth administration is being streamlined in a number of purposes. Lately, Australian warmth switch specialist Conflux Know-how partnered with Italian hypercar maker Pagani to enhance the thermal efficiency of the Pagani Utopia’s transmission.

The Australian specialist developed a 3D printed cartridge warmth exchanger for the 6-liter twin-turbo V12-powered automobile, attaining a 30% enhance in warmth rejection in comparison with the earlier design. This enchancment helps world emissions compliance and ensures thermal reliability below excessive driving circumstances. Testing by Pagani confirmed the brand new system’s sturdiness and effectiveness, assembly efficiency requirements for each observe and highway use.

For analysis final 12 months, Diamond Exhausting Surfaces labored with Additive Analytics, a spinout from the College of Wolverhampton, to develop embedded digital warmth spreaders that enhance thermal dissipation in electronics and CPUs. Shifting past conventional subtractive manufacturing strategies, the undertaking leveraged 3D printing to create complicated geometries that enhance warmth alternate effectivity and cooling efficiency.

The event mixed Diamond Exhausting Surfaces’ patented processes with Additive Analytics’ materials growth and laser processing experience. This method allowed for the manufacturing of warmth spreaders with greater floor area-to-volume ratios, serving to to forestall sizzling spots and lengthen the lifespan of compact, high-performance units.

Take the 3DPI Reader Survey — form the way forward for AM reporting in below 5 minutes.

What 3D printing traits must you be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals PSU PhD candidate, Tatiana El Dannaoui, putting in radiator prototype in thermal vacuum take a look at facility to simulate area setting operation. Picture by way of PSU.