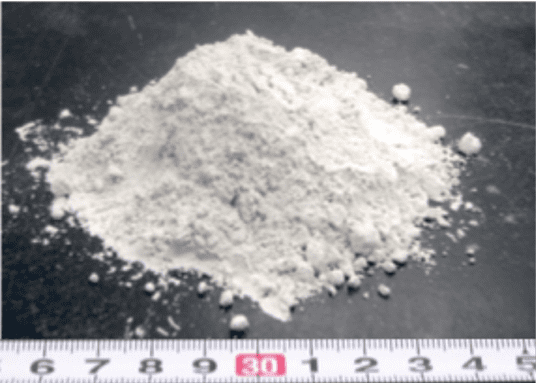

Researchers in Japan have developed a seemingly extra sustainable different to Portland cement, within the type of a geopolymer-based soil solidifier developed from Siding Reduce Powder (SCP), a building waste byproduct, and Earth Silica (ES), sourced from recycled glass.

The strategy guarantees to divert building waste from landfill, and switch it right into a high-value building enter.

Whereas geopolymers have beforehand been explored as potential replacements for cement, this newest work seems to be important for combining two waste merchandise, whereas reaching excessive efficiency and resilience to excessive situations. It additionally addresses engineering challenges similar to arsenic leaching, that may in any other case hinder the trouble to make use of such supplies in building.

A paper detailing the tactic was revealed within the Cleaner Engineering and Expertise journal in Might by researchers from the Shibaura Institute of Expertise (SIT).

Because the group explains, the mixture of SCP and ES kinds a geopolymer-based solidifier able to enhancing soil-compressive power past construction-grade thresholds of 160 kN/m2.

Thermally treating SCP at 110 °C and 200 °C is an important step that enhances its reactivity and permits for lowered materials utilization with out compromising efficiency.

SIT’s Professor Shinya Inazumi mentioned: “This analysis represents a big breakthrough in sustainable building supplies.”

“Through the use of two industrial waste merchandise, we developed a soil solidifier that not solely meets business requirements but additionally helps handle the twin challenges of building waste and carbon emissions.”

Environmental security has additionally obtained consideration within the strategy, addressing issues with arsenic leaching that may hamper efforts to reuse recycled glass content material. Inazumi mentioned: “Sustainability can’t come on the expense of environmental security. Most significantly, we recognized and solved a possible environmental concern: when arsenic leaching was detected in preliminary formulations, we demonstrated that incorporating calcium hydroxide successfully mitigated this problem by the formation of secure calcium arsenate compounds, guaranteeing full environmental compliance.”

He outlined quite a few sensible functions with wide-reaching real-world impression. For instance, in city infrastructure, to stabilize weak soils beneath roads, buildings, and bridges with out counting on carbon-intensive Portland cement.

“That is notably precious in areas with problematic clay soils the place typical stabilization strategies are expensive and environmentally burdensome.”

Catastrophe-prone areas may gain advantage from fast soil stabilization utilizing these supplies, which he mentioned had demonstrated good workability and setting instances appropriate with emergency response wants. As well as, rural infrastructure tasks in growing areas might deploy the supplies to create stabilized soil blocks for building, offering a low-carbon different to fired bricks or concrete.

The answer additionally appears to reply a necessity for higher decarbonization within the building sector, with the geopolymer solidifier providing another that seems to exceed the efficiency of conventional strategies however with a lighter carbon footprint.

And for geotechnical engineering, the outcomes seem to ascertain sturdiness below excessive situations (i.e., sulphate assault, chloride ingress, freeze-thaw cycles).

By changing Portland cement, the strategy helps efforts to adjust to inexperienced constructing certifications and carbon discount targets.

Cement manufacturing presently accounts for 7–8% of worldwide CO2 emissions.