A brand new n-channel MOSFET in a slim 8×8 mm bundle units a benchmark with simply 0.88 mΩ RDS(on), 0.36 °C/W thermal resistance, and enhanced solderability — very best for high-efficiency, space-constrained industrial designs.

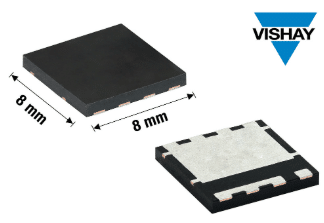

Vishay Intertechnology has launched a brand new 80 V n-channel energy MOSFET — the SiEH4800EW — designed to ship best-in-class efficiency in demanding industrial purposes. This newest addition to Vishay’s TrenchFET Gen IV household is housed within the compact PowerPAK 8x8SW bond wi-fi (BWL) bundle and stands out with an exceptionally low typical on-resistance (RDS(on)) of simply 0.88 mΩ at 10 V. This represents a 15% discount in RDS(on) in comparison with competing gadgets in the identical footprint, resulting in considerably decrease conduction losses and improved energy effectivity.

The important thing options embody:

- Low thermal resistance: RthJC of simply 0.36 °C/W — 18% decrease than comparable MOSFETs

- Compact measurement: 8 mm x 8 mm footprint saves 50% PCB area vs. TO-263 packages

- Extremely-thin profile: Only one mm thick, very best for space-constrained designs

These attributes make it very best for space-constrained purposes requiring excessive effectivity and thermal efficiency. To assist enhanced solderability and thermal design, the MOSFET includes a fused lead construction that expands the supply PAD solderable space to three.35 mm² — 4 occasions that of standard PIN-style designs. This lowers present density between the MOSFET and PCB, mitigating electro-migration and bettering long-term reliability. Moreover, its wettable flanks guarantee dependable solder joints and simplify visible inspection throughout manufacturing.

The SiEH4800EW is tailor-made for purposes similar to motor drives, energy instruments, welding machines, battery administration techniques, robotics, plasma cutters, and 3D printers. With a excessive present functionality of as much as 608 A and working temperatures as much as +175 °C, it delivers excellent efficiency even beneath harsh circumstances. Its BWL structure additional minimizes parasitic inductance, enhancing total system effectivity.

Totally RoHS-compliant and halogen-free, the SiEH4800EW can also be 100% Rg and UIS examined to make sure reliability. Samples and manufacturing portions are actually obtainable with a typical lead time of 13 weeks, making this system an instantaneous answer for engineers searching for compact, environment friendly, and strong energy switching.

For extra data,click on right here.