A overview printed in Digital and Bodily Prototyping explores the rising area of additively manufactured acoustic metamaterials (ACA-Meta), highlighting how 3D printing applied sciences allow novel designs for efficient sound absorption throughout various purposes. Authored by researchers from Khalifa College and Dassault Aviation, the paper classifies acoustic metamaterials into perforated, slotted, mobile, and hybrid varieties and investigates how additive manufacturing enhances their efficiency.

Increasing acoustic management with 3D printing

Additive manufacturing presents distinctive advantages for acoustic metamaterials, enabling exact management over geometry, materials distribution, and inside structure. This degree of management permits researchers and engineers to tailor acoustic conduct at particular frequency ranges, whereas concurrently optimizing for weight, mechanical power, and structural complexity.

Conventional sound-absorbing supplies, corresponding to porous foams or fibrous panels, are sometimes constrained by fastened properties and restricted adaptability. In distinction, 3D printing permits designers to create resonant buildings and inside cavities with sub-wavelength precision, a vital consider manipulating how sound waves work together with matter.

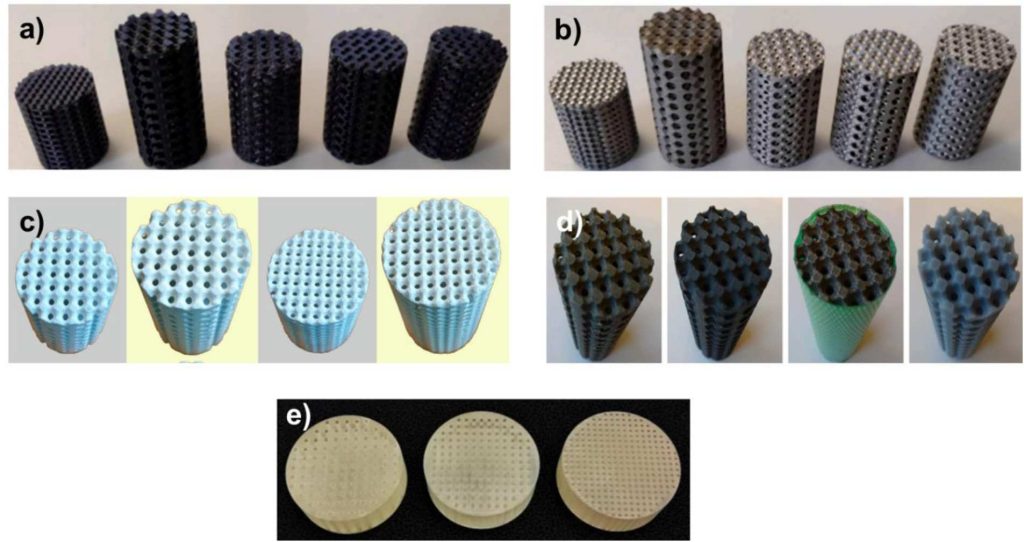

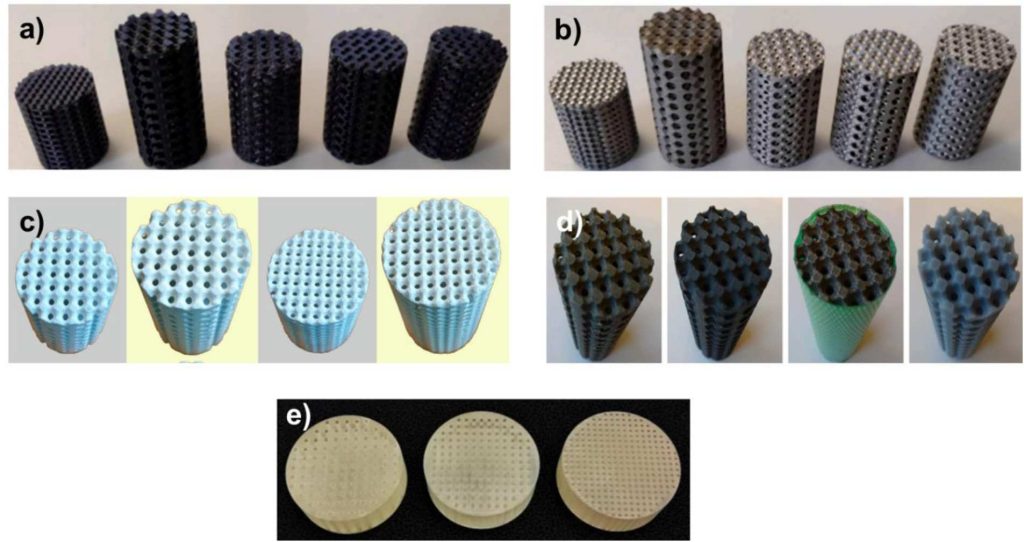

The overview outlines how methods corresponding to Stereolithography (SLA), Selective Laser Melting (SLM), Fused Deposition Modeling (FDM), and Digital Gentle Processing (DLP) are being employed to manufacture a brand new era of acoustic absorbers. These processes allow the development of intricate geometries beforehand unattainable with standard manufacturing, and permit for the fine-tuning of key parameters corresponding to pore measurement, wall thickness, infill density, and materials gradients. In doing so, additive manufacturing not solely improves absorption effectivity but additionally broadens the usable frequency vary of those metamaterials, making them extra adaptable to particular environments and industrial necessities.

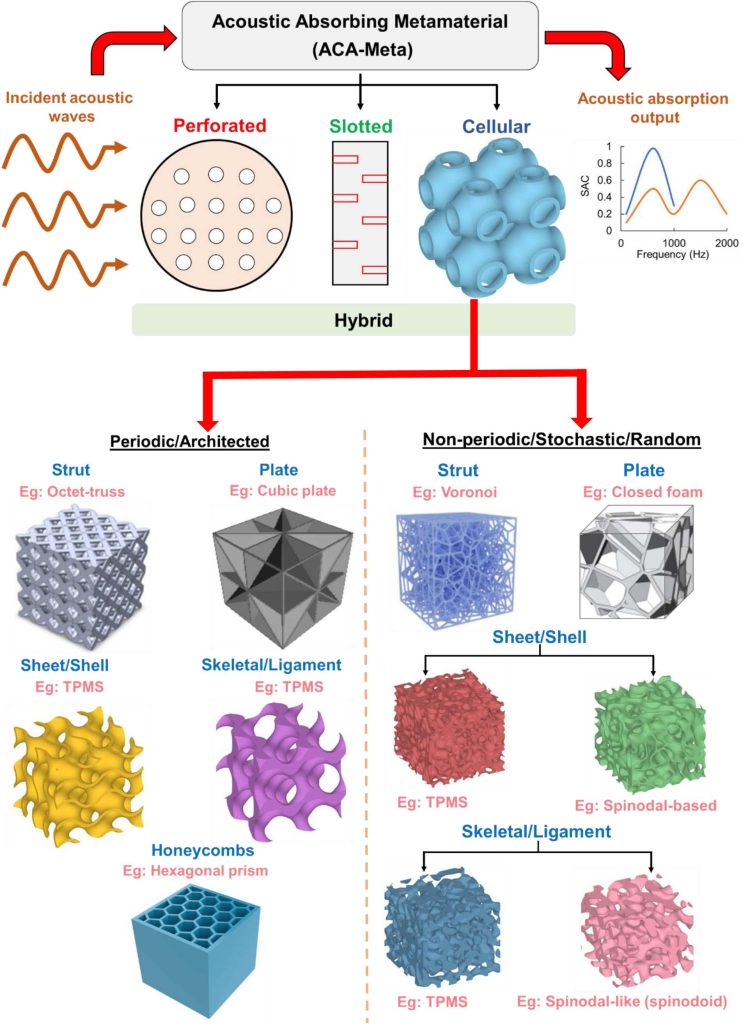

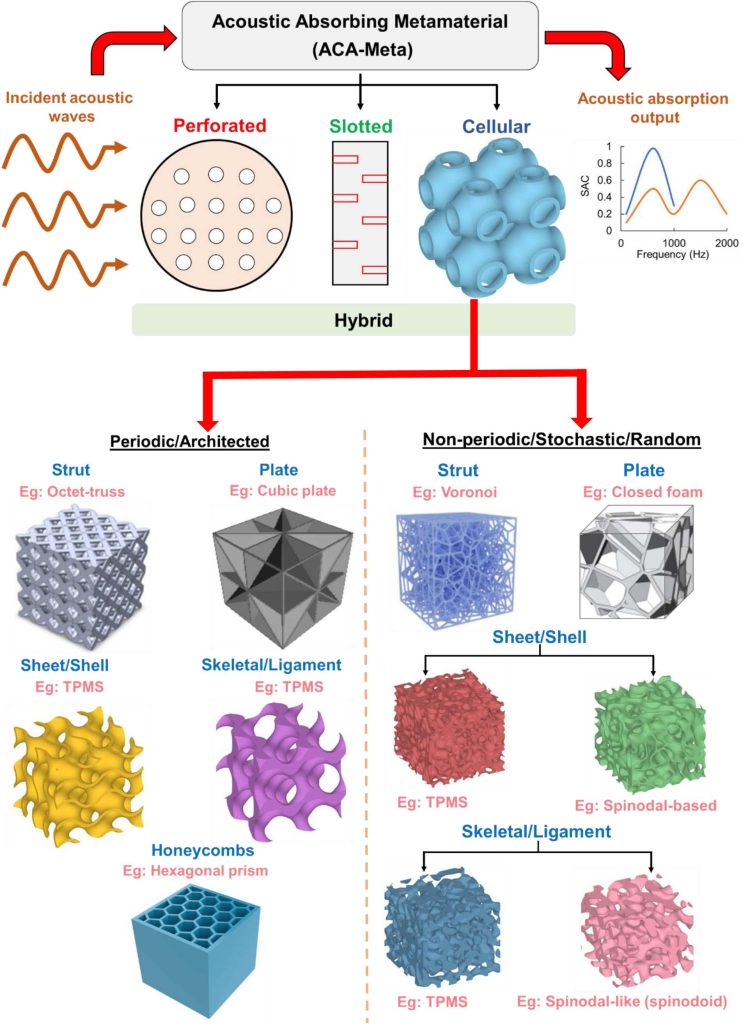

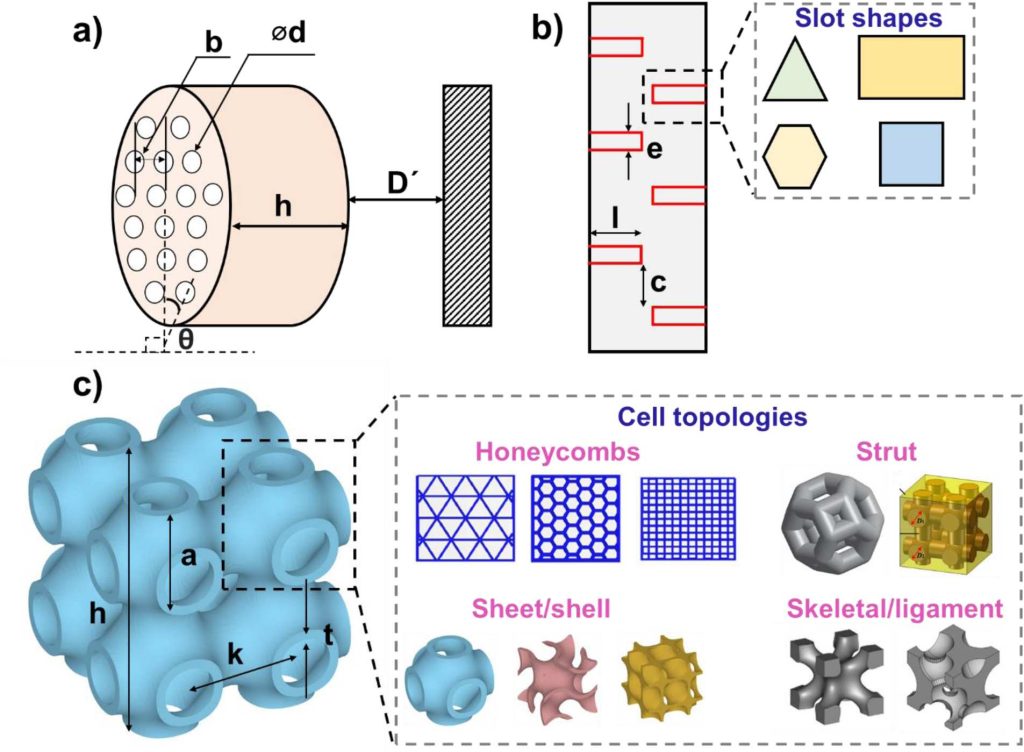

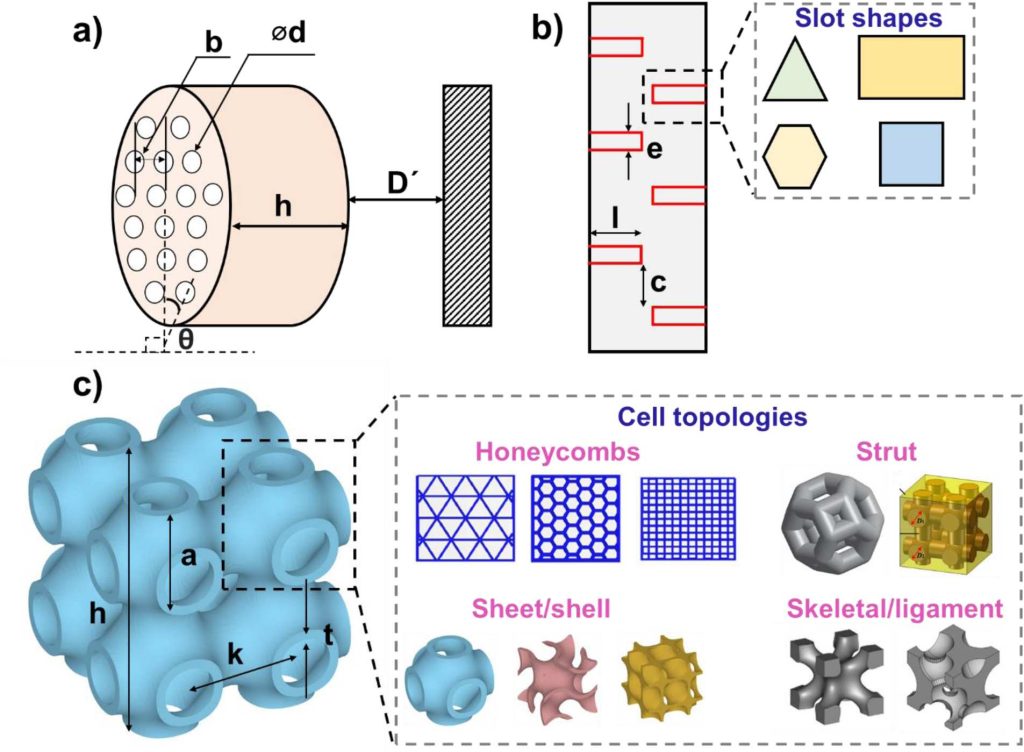

The paper categorizes these acoustic metamaterials into 4 structural households, every with distinctive mechanisms for managing sound waves. Perforated metamaterials take in mid- to high-frequency noise by dissipating power by means of arrays of micro-holes, typically backed by air cavities to reinforce low-frequency efficiency. Slotted designs make use of labyrinthine or coiled channels to increase the acoustic path size, enabling efficient attenuation at low frequencies inside a compact footprint. Mobile buildings, together with periodic honeycombs, gyroids, and stochastic foams, are engineered to exhibit broadband efficiency by means of managed porosity and inside resonance. Lastly, hybrid designs mix a number of options, corresponding to perforated faces with embedded coiled cavities or layered mobile cores, to attain tunable, wideband absorption throughout a number of acoustic regimes.

These classifications are usually not merely theoretical; every has been demonstrated by means of experimental validation, with efficiency metrics corresponding to sound absorption coefficient (SAC) measured utilizing impedance tubes and reverberation chambers. The paper emphasizes that even minor design modifications, like altering the angle of perforations or grading cell density, can have vital results on absorption efficiency, reinforcing the worth of additive manufacturing as each a prototyping and manufacturing instrument in acoustic engineering.

Simulation and experimental validation

To quantify acoustic absorption, the research opinions each analytical fashions and experimental strategies. Key parameters embrace the sound absorption coefficient (SAC), floor porosity, and pattern orientation. Validation methods corresponding to impedance tube and reverberation room testing present that additively manufactured metamaterials can obtain or exceed the efficiency of conventional absorbers.

The overview additionally identifies future instructions, together with volumetric 3D printing, multi-material printing, and 4D printing utilizing sensible supplies for tunable acoustic responses. These approaches promise scalable, reconfigurable absorbers that may adapt to environmental adjustments or user-defined inputs.

Reshaping acoustic metamaterials

Curiosity within the acoustic capabilities of 3D printing has grown considerably lately. In 2019, researchers on the College of Sussex demonstrated a 3D printed metamaterial able to directing sound to a particular location with out the usage of headphones, an early instance of how additive manufacturing might redefine private audio supply. Extra just lately, the College of Strathclyde acquired £500,000 in funding to develop miniaturized acoustic programs utilizing 3D printing, aiming to advance compact and high-performance units for sensing and communication.

Client audio manufacturers have additionally embraced the know-how; Campfire Audio, as an example, leveraged additive manufacturing to create earphones inside construction for his or her Supermoon collection, optimizing each sound efficiency and match. On a extra experimental entrance, researchers have begun utilizing sound itself as a medium for fabrication, as seen in a current research on holographic Direct Sound Printing (DSP), which manipulates ultrasonic fields to solidify resin.

Collectively, these developments underscore the rising convergence of 3D printing and acoustic innovation, a convergence that the reviewed paper situates throughout the rising area of engineered sound-absorbing metamaterials.

Learn the total article in Digital and Bodily Prototyping

Subscribe to the 3D Printing Trade publication to maintain up with the most recent 3D printing information.You may as well comply with us on LinkedIn and subscribe to the 3D Printing Trade YouTube channel to entry extra unique content material.

At 3DPI, our mission is to ship high-quality journalism, technical perception, and trade intelligence to professionals throughout the AM ecosystem.

Assist us form the way forward for 3D printing trade information with our 2025 reader survey.

Function picture reveals ACA-Meta fabricated by varied additive manufactured methods.