Researchers on the College of North Texas have developed a real-time in-situ ultrasound monitoring system able to monitoring gentle hydrogel 3D printing processes with subwavelength decision. The work, printed in Communications Engineering, supplies new strategies for observing important transient phenomena throughout the additive manufacturing of gelatin-alginate hydrogels, together with layer bonding, floor deformation, and gravitational spreading.

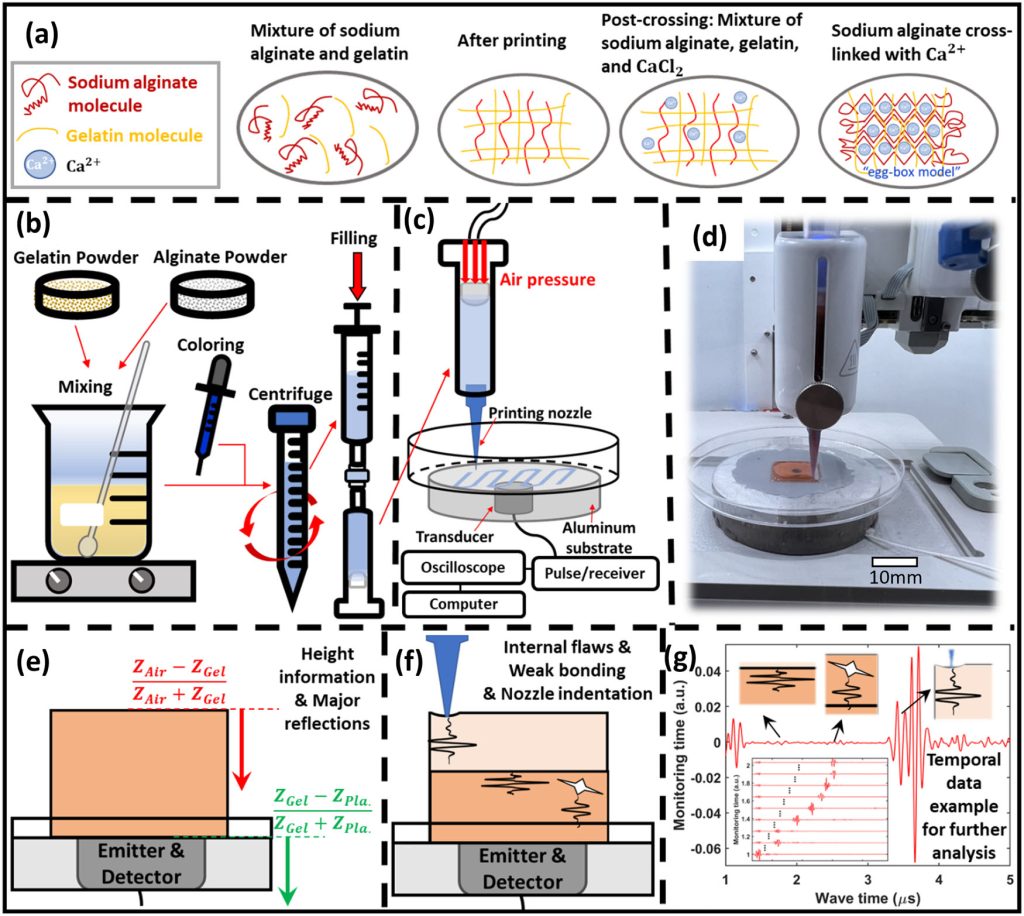

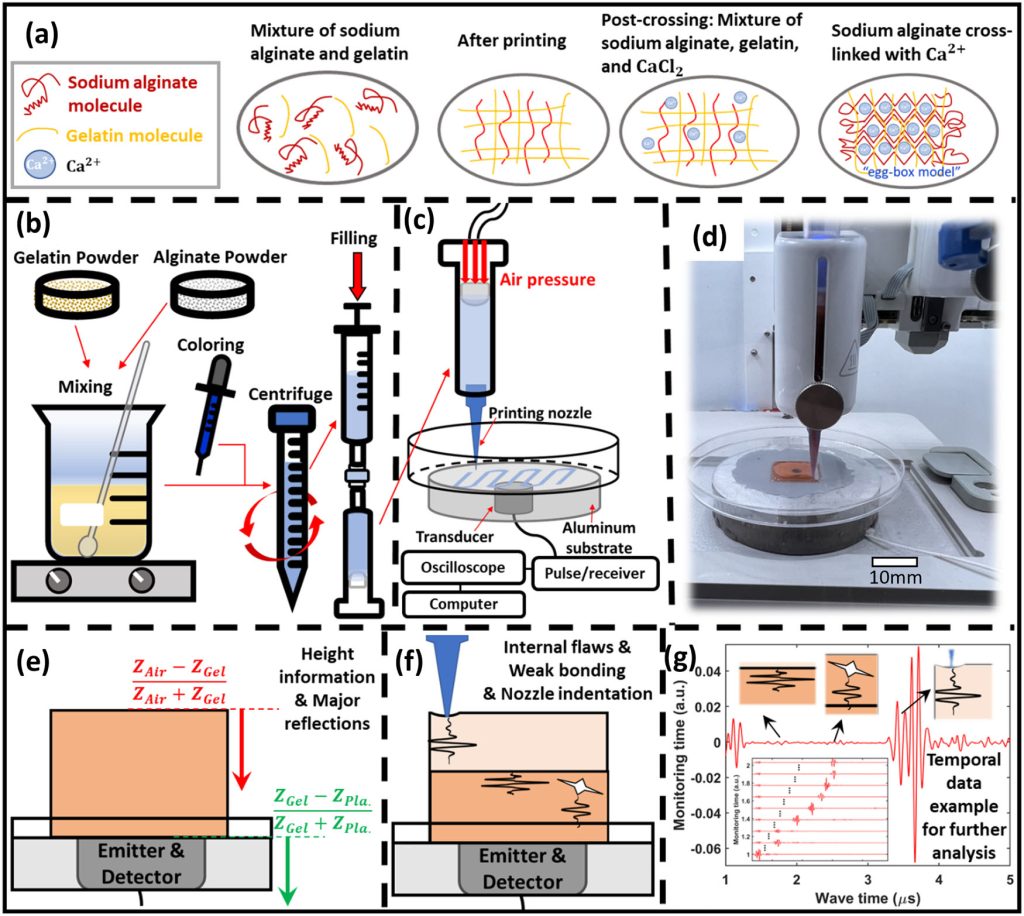

The analysis workforce, led by Yuqi Jin and Arup Neogi, built-in a ten MHz immersion ultrasound transducer right into a BIO X bioprinter platform. Their system permits for the continual assortment of acoustic indicators as materials is deposited, enabling high quality management not solely throughout printing but additionally throughout post-processing equivalent to ionic crosslinking.

Ultrasound as a software for bioprint high quality management

Whereas optical strategies like OCT and X-ray imaging have been explored for AM monitoring, they’re usually restricted by materials opacity or electromagnetic interference. In distinction, ultrasound affords higher penetration depth and is appropriate with excessive water-content hydrogels. The workforce’s setup used a monostatic configuration with a transducer embedded in a customized aluminum substrate to trace the mirrored waveforms of every printed layer in real-time.

Numerical simulations utilizing COMSOL Multiphysics have been used to mannequin sign conduct throughout printing. The ultrasound reflections enabled the researchers to detect minute modifications in layer thickness, elasticity, and mechanical disturbances brought on by nozzle scratching or inconsistent extrusion.

Monitoring geometry, floor high quality, and materials conduct

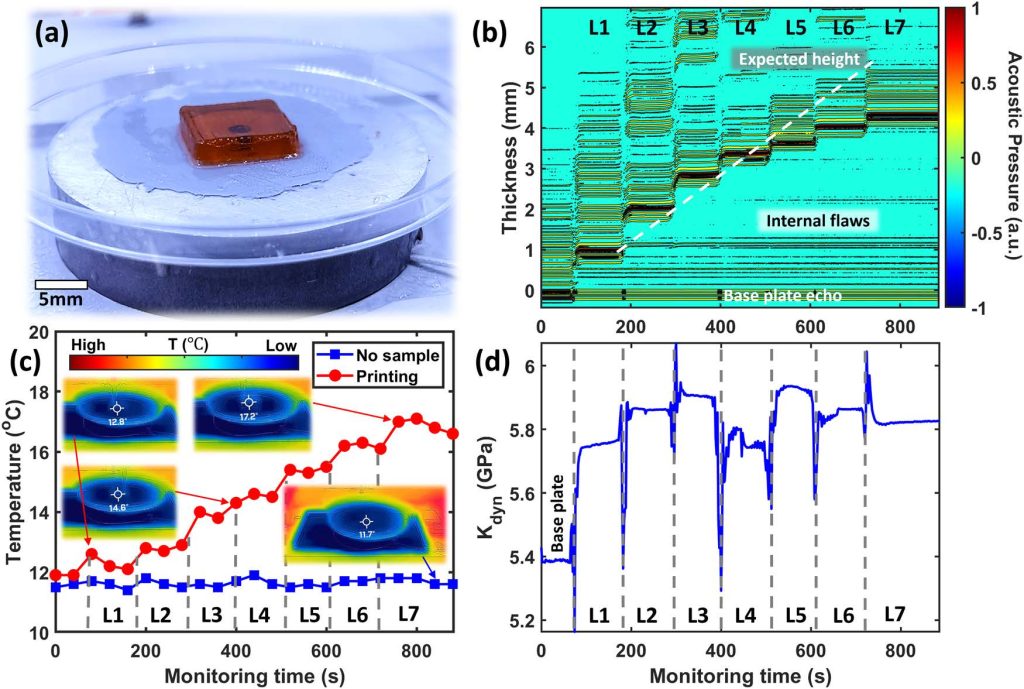

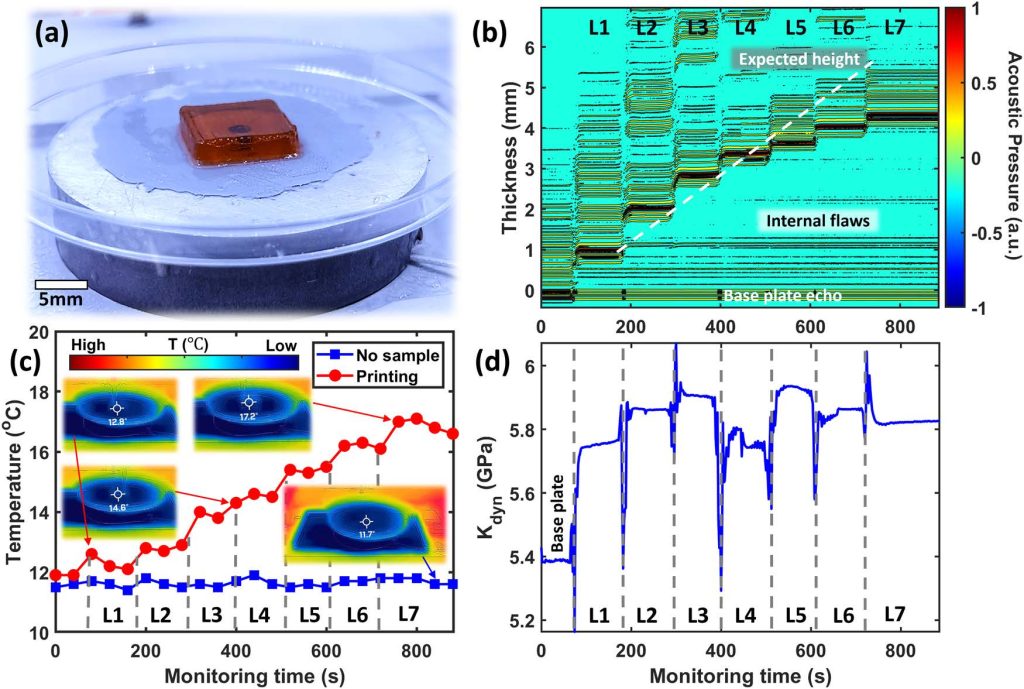

In assessments utilizing totally infilled hydrogel blocks, the researchers noticed clear acoustic indicators of geometry build-up, adopted by layer top degradation brought on by cumulative weight and nozzle contact. Fourier evaluation of mirrored indicators revealed each elastic and plastic deformations, with frequency dispersion correlating to floor roughness.

The ultrasound system was additionally examined on grid-infused scaffold prints, revealing gravitational sagging and structural shrinkage as a result of unsupported geometry. These phenomena, tough to detect by way of typical ex-situ strategies, have been visualized by means of section spectra and dynamic bulk modulus (DBM) profiles.

The workforce additional prolonged monitoring to the post-crosslinking stage. By immersing samples in CaCl₂ answer, they noticed real-time stiffening of the printed constructions alongside geometric distortion. Monitoring enabled the identification of optimum crosslinking durations to boost mechanical properties with out compromising structural integrity.

Towards sensible bioprinting programs

The in-situ ultrasound system demonstrated on this research supplies a pathway towards real-time defect detection, parameter tuning, and automatic course of optimization for gentle materials 3D printing. Though presently restricted to localized measurements, the authors suggest increasing the system utilizing 2D phased arrays for full-plane protection and integration with closed-loop suggestions programs.

By offering perception into delicate mechanical and geometrical modifications throughout bioprinting, the system may help in producing constant, high-quality hydrogel constructs for tissue engineering, drug supply, and regenerative medication purposes.

This analysis builds on current developments in hydrogel-based additive manufacturing. In 2021, scientists developed a high-strength seaweed-based hydrogel for 3D printing purposes, highlighting alginate’s mechanical potential. Extra not too long ago, 3D printed hydrogels have been explored for radiation shielding in house environments, underscoring their useful versatility. In the meantime, a research on xolography launched a volumetric strategy for fabricating gentle tissue constructs, pushing the boundaries of bioprinting decision. These advances underscore the necessity for sturdy, real-time monitoring programs, such because the ultrasound-based strategy demonstrated within the present research, to make sure high quality management and reproducibility throughout complicated hydrogel printing processes.

Learn the complete article in Communications Engineering

Subscribe to the 3D Printing Business e-newsletter to maintain up with the most recent 3D printing information.

It’s also possible to comply with us on LinkedIn and subscribe to the 3D Printing Business YouTube channel to entry extra unique content material.

At 3DPI, our mission is to ship high-quality journalism, technical perception, and trade intelligence to professionals throughout the AM ecosystem. Assist us form the way forward for 3D printing trade information with our 2025 reader survey.

Featured picture exhibits in-situ monitoring experimental outcomes from the printing of grided block. Picture by way of Communications Engineering / College of North Texas.